PUHY-YMC

Contents

Before installation and electric work

Safety precautions

Before getting installed

Before getting installed moved electrical work

Before starting the test run

Combination with indoor units

Confirmation of parts attached

Model Name Connecting pipe Elbow Shape

Outdoor unit configuration

Selection of installation site

Variable capacity unit Constant capacity unit

When there is an obstruction above the unit

Individual installation

When inlet air enters from right and left sides of unit

Space required around unit

Collective installation and continu- ous installation

Lifting method and weight of product

Be very careful to carry product

Example of collective installation

Installation of unit

Installation

Location of anchor bolt

60/61 dB A-weighted

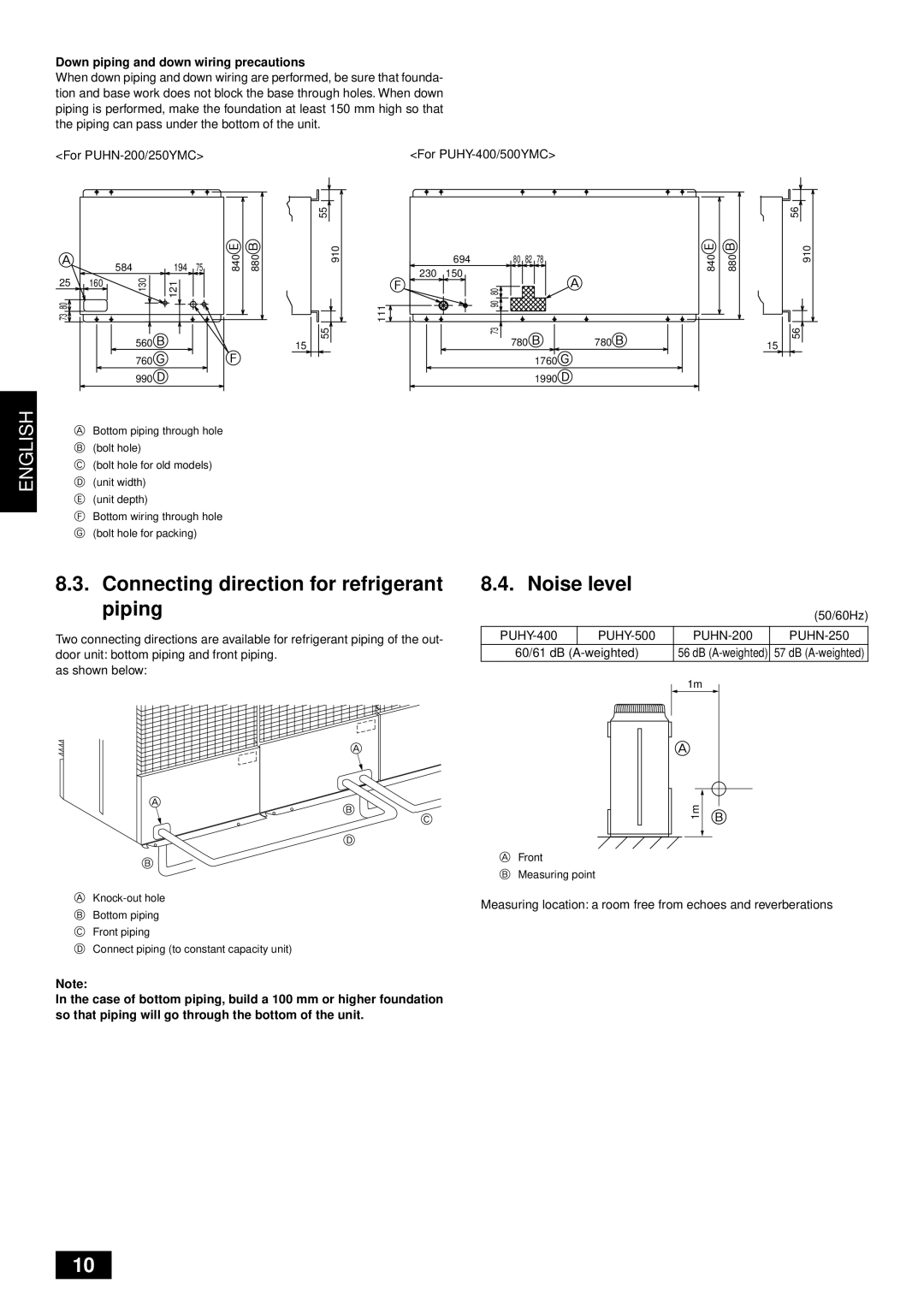

Connecting direction for refrigerant piping

Down piping and down wiring precautions

Noise level

PUHY-400/500YMC

Snow and seasonal wind

Countermeasure to seasonal wind

PUHN-200/250YMC

Areas of caution

Refrigerant piping installation

Never perform a pump down. This will damage the compressor

Refrigerant piping system

+ α

Multiple line/header

Precautions concerning piping connection and valve operation

For variable capacity unit

Gas side Liquid side Oil balance side

Figure shows valve fully open

100 to 1000 to Tightening angle standard Pipe diameter mm

50 to 57.5 / 500 to

75 to 750 to

60 to

Oil balance pipe connection method

Distributor gas connection method

Part could be damaged if not cooled sufficiently

Restrictions on the posture for attaching joints

How to install branch pipe

Joint

Gram below

Airtight test

Airtight test and evacuation

Evacuation

No heat insulation must be provided for electric wires

Thermal insulation of refrigerant piping

Penetrations

Inner wall concealed Floor fireproofing

Electrical work

Variable capacity unit

Control box and connecting posi- tion of wiring

Constant capacity unit

Hole

For details, see item 11.3. Wiring transmission cables

Plate

Transmission booster optional

Wiring examples

Wiring transmission cables

Connecting a transmission booster

Name, code and possible unit connections

One remote control unit for each indoor unit

Wiring method, address setting

Remote control RC terminal block TB6

Within Address Unit Remote control operation Same as above

For details, see wire connection example C

Unit Range Setting method

Wiring Line

Same group to the remote control RC terminal block TB6

Main remote controller

Extended length and the length to the most remote unit

Booster RP

Wiring

Capability Number of connected indoor units that can be

Wiring of main power supply and equipment capacity

Checking before getting test run

Operation procedure

Test run

Test run method

How to cope with test run abnormality

Abnormality

Display at LED lighting blinking Remarks Flag Relay output

6603 Transmission error Transmission route Busy Error

Power on

Flag 8 always lights

Coping with remote controller abnormality

Following phenomena do not represent abnormality emergency

NMK

Nknk

Nkok

NKPK#$%&*+

Nkqk

#$%&*+#,%&- ./0123145&6789#$%&=?@. !#

Sknk

Skok

#$% +,-.Ü

TK=

Uknk

Ukok

Ukpk Ukqk

Vkok

NMK=

Nmknk =

NMKOK=

$%&*+,-./01

#$%&*+QMã

NMKPK=L

NMKQK=

Ãã ! k·ãLâÖJÅã

#$%&#*#%+, -. !*#

NMKRK=

NMKSK=

#$%& *+& 012345678 .#$%&*+,-./0 1$%#234

NNK=

NNKNK=

NNKOK=

NNKPK=

Rsrv

#$% +,-./012

NRO

#$% +,-./0/12`kQN

=EqRF= !# $%&*+

NNKQK=

Vwt

NOKNK=

NOKOK=

NOKPK=

EptNF EibaF

NOKQK=

Nokrk

`ççäáåÖ EÉ~íáåÖ

NMK

Nknk

Nkqk

#$%&!*+

Sknk

Skok

TK=

Ukok

Ukpk Ukqk

Vkok

NMK=

NMKOK=

#$%&*+QMã

NMKPK=L

NMKQK=

#$%&#*#%+, -. !*#

NMKRK=

NMKSK=

#$%& *+& 012345678 .#$%&*+,-./0 1$%#234

NNK=

NNKOK=

NNKPK=

#$% +,-./012

NRO

#$#%&* +,-./0123456

=EqRF= !# $%&*+

NNKQK=

NOK=

NOKPK=

EptNF EibaF

NOKQK=

Nokrk

WT02922X02