MODELS:

Using Lead Free Solder

The symbol shown below indicates Lead (Pb) Free |

| • Poor |

| ||||

solder was used during the construction of PWBs. |

| • Higher temperatures can cause flux spattering. | |||||

Only Lead Free solder should be used when servic- | • Soldering iron tip life is shortened. |

| |||||

ing these PWBs. |

|

| • Dull finish solder joints (not shiny) can appear to be | ||||

Solder must be compatible with that used by the |

| a “cold” solder joint. |

|

| |||

|

|

|

|

|

| ||

manufacturer. Leaded solder can not be used on |

| In general a tip temperature of 700° F will usually provide | |||||

PWBs manufactured with | good results. |

|

|

|

| ||

ishi standard for service requires the use of |

|

|

|

|

| ||

Copper | Displays used to indicate | ||||||

through the Parts Department. |

|

| |||||

Order part number: PB FREE SOLDER |

|

| PCBs will be marked, indicating the level of | ||||

|

|

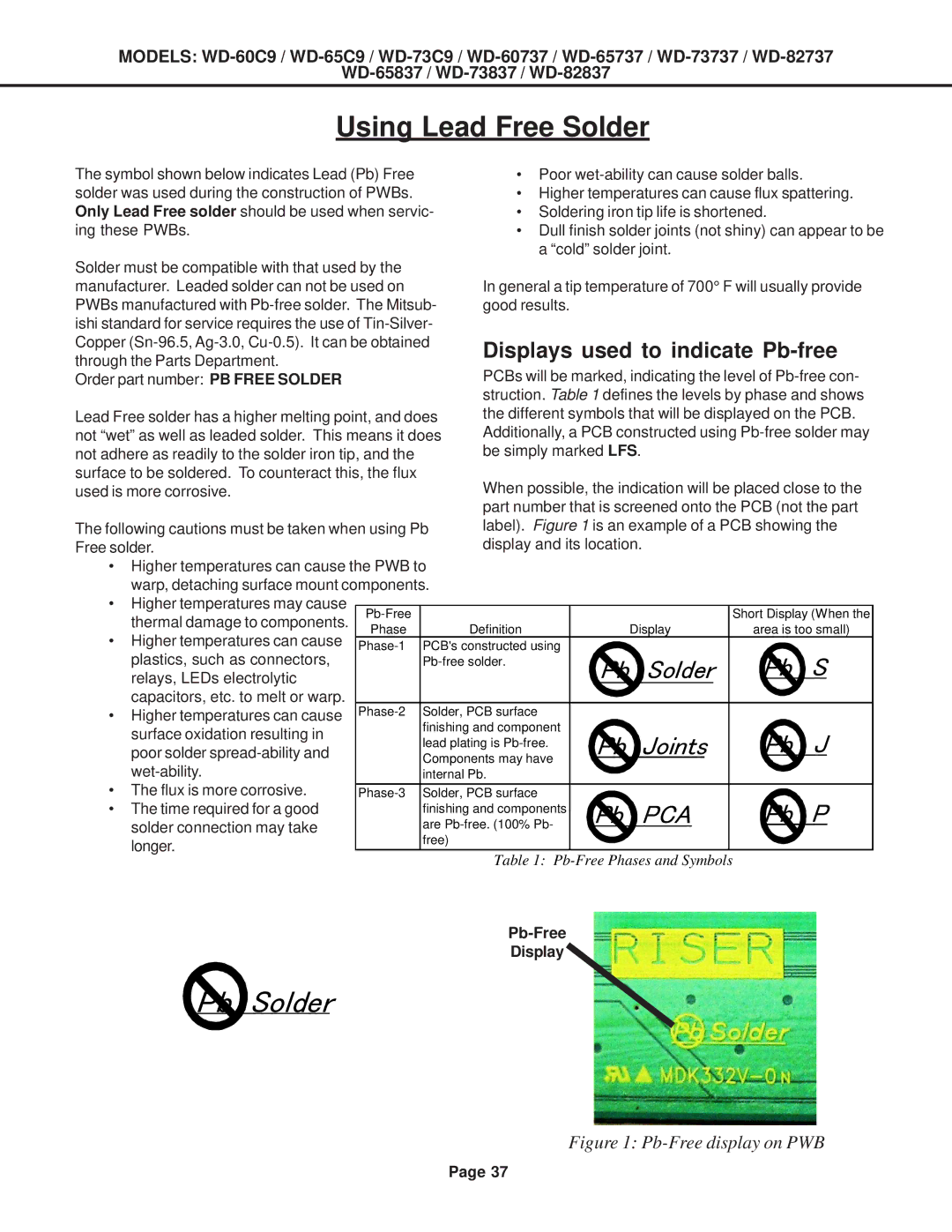

| struction. Table 1 defines the levels by phase and shows | ||||

Lead Free solder has a higher melting point, and does | the different symbols that will be displayed on the PCB. | ||||||

not “wet” as well as leaded solder. This means it does | Additionally, a PCB constructed using | ||||||

not adhere as readily to the solder iron tip, and the |

| be simply marked LFS. |

|

| |||

surface to be soldered. To counteract this, the flux |

| When possible, the indication will be placed close to the | |||||

used is more corrosive. |

|

| |||||

|

|

| part number that is screened onto the PCB (not the part | ||||

The following cautions must be taken when using Pb | label). Figure 1 is an example of a PCB showing the | ||||||

Free solder. |

|

| display and its location. |

|

| ||

• Higher temperatures can cause the PWB to |

|

|

|

|

| ||

warp, detaching surface mount components. |

|

|

|

|

| ||

• Higher temperatures may cause |

|

|

|

| Short Display (When the | ||

thermal damage to components. |

|

|

|

| |||

Phase |

| Definition |

| Display | area is too small) | ||

• Higher temperatures can cause |

|

| |||||

PCB's constructed using |

|

|

|

| |||

plastics, such as connectors, |

| Pb | Solder | Pb | S | ||

relays, LEDs electrolytic |

|

|

| ||||

|

|

|

|

|

|

| |

capacitors, etc. to melt or warp. | Solder, PCB surface |

|

|

|

| ||

• Higher temperatures can cause |

|

|

|

| |||

surface oxidation resulting in |

| finishing and component | Pb | Joints | Pb | J | |

| lead plating is | ||||||

poor solder |

| ||||||

| Components may have |

|

|

|

| ||

| internal Pb. |

|

|

|

| ||

• The flux is more corrosive. | Solder, PCB surface |

|

|

|

| ||

• The time required for a good |

| finishing and components | Pb | PCA | Pb | P | |

solder connection may take |

| are |

|

|

|

| |

longer. |

| free) |

|

|

|

|

|

Table 1:

Display

Pb Solder

Figure 1: Pb-Free display on PWB

Page 37