Mode D’EMPLOI ET D’ENTRETIEN

Instructions for USE

Instrucciones DE USO

Instruções DE USO

14 15

Terra 5200B 146 1996

Maintenance

Safety Functions

Troubleshooting Scrapping

Instructions for USE Introduction

Introduction

Instructions for USE General Instructions

Unpacking

Machine Description

Terra 5200B Sweeper Operation

Conventions

Description

Instructions for USE Technical Data

Wiring diagram See Fig. AF

ACCESSORIES/OPTIONS

Battery CHECK/SETTING on a NEW Machine

USE

Fuses

Battery Installation and WET or GEL Battery Setting

Battery installation

WET or GEL battery setting

Before Machine START-UP

Instructions for USE Starting and Stopping the Machine

Machine Operation

Starting the machine

Stopping the machine

Working Light Adjustment

Instructions for USE Hopper Dumping

Machine Long Inactivity

First Period of USE

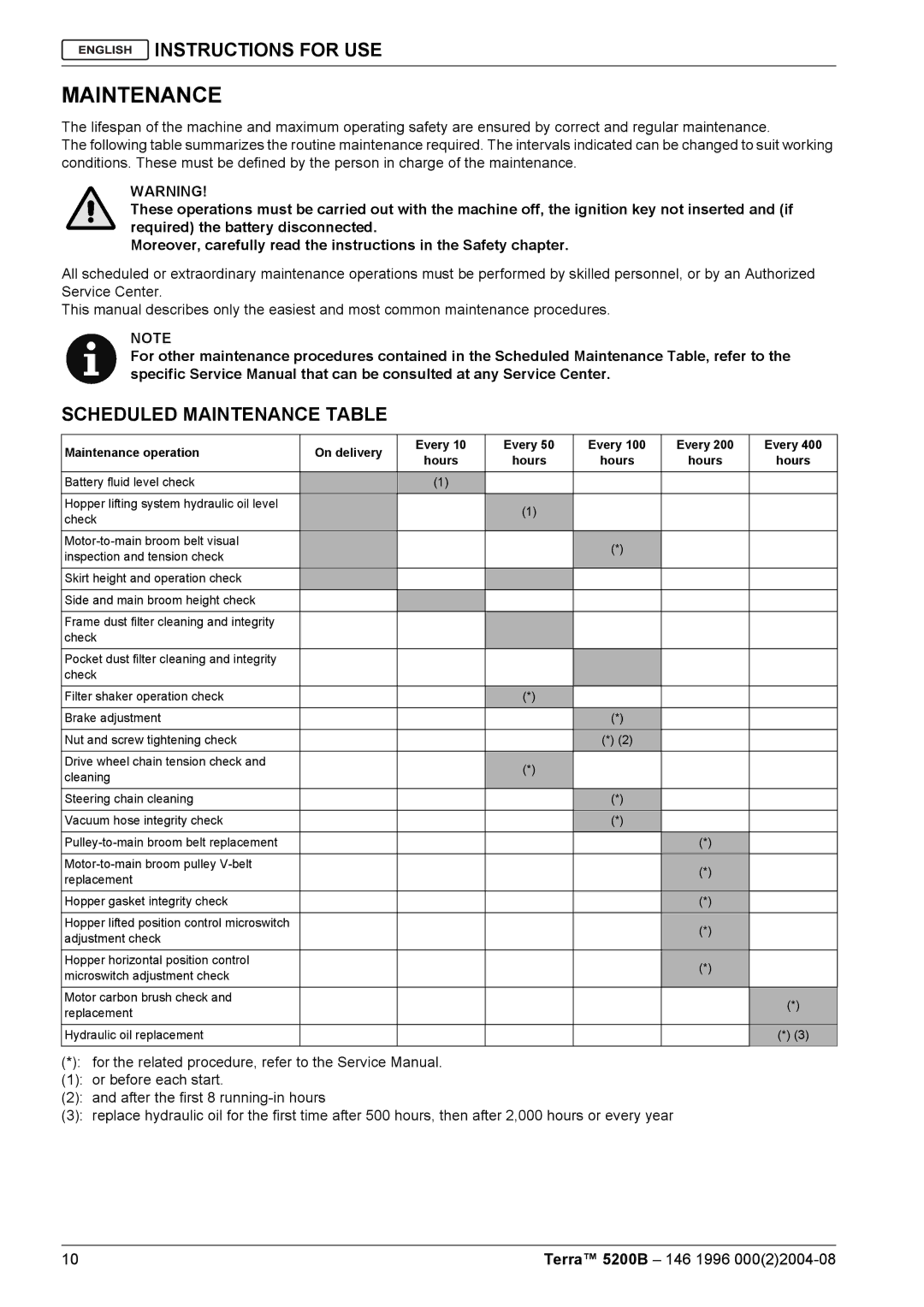

Maintenance

Scheduled Maintenance Table

This procedure is applicable to all types Brooms

Brooms of various hardness are available

Tighten the locknut 2, Fig. E

Brooms of various hardness are available

Remove the internal pocket separator 7, Fig. AC

Battery Charging

Skirt Height and Operation Check

Hopper Lifting System Hydraulic OIL Level Check

Side skirt

Safety Functions

Troubleshooting

Scrapping

Instrucciones DE USO Introducción

Descripción DE LA Máquina

USO

Mantenimiento

Introducción

Instrucciones DE USO Instrucciones Generales

Desembalaje

Descripción DE LA Máquina

Convenciones

Descripción

Instrucciones DE USO Datos Técnicos

Esquema eléctrico Véase Fig. AF

Códigos colores BK Negro BU Azul BN Marrón GN Verde GY Gris

USO

Fusibles

ACCESORIOS/OPCIONES

CONTROL/PREPARACIÓN Baterías EN LA Máquina Nueva

Antes DE LA Puesta EN Marcha DE LA Máquina

Sin baterías

Instalación de las baterías

Regulación de batería WET o GEL

Máquina EN Función

Puesta en marcha

Parada de la máquina

Máquina

Ajuste DE LA LUZ DE Trabajo

Periodo DE Larga Inactividad DE LA

Primer Periodo DE Utilización

Mantenimiento

Esquema DE Mantenimiento Programado

Hay cepillos con cerdas más o menos

Mm 0,79 1,57

Instrucciones DE USO Control Y Ajuste DE LA Altura DEL

Cepillo Lateral Laterales

Los filtros de bolsas de fibra de poliéster

Necesitan una limpieza mucho más

Además del filtro de papel estándar, hay

Estos tipos Procedimiento siguiente

Control Altura Y Funcionamiento DE LAS Puertas Abatibles

Carga DE LAS Baterías

Puerta abatible lateral

Funciones DE Seguridad

Búsqueda Averías

Interruptor DE Asenso Marcha

Pulsador DE Emergencia

Eliminación

Mode D’EMPLOI ET D’ENTRETIEN Introduction

Description DE LA Machine

Utilisation

Entretien

Mode D’EMPLOI ET D’ENTRETIEN

Symboles Utilises

But ET Contenu DU Manuel

Destinataires

Mode Demploi ET Dentretien Instructions Generales

Mode D’EMPLOI ET D’ENTRETIEN Deballage

Description DE LA Machine

Capacites Operationnelles DE Terra 5200B

Mode Demploi ET Dentretien Caracteristiques Techniques

Schéma électrique Voir Fig. AF

BE1 Feu clignotant optionnel BZ1

Arrière

ACCESSOIRES/OPTIONS

Utilisation

CONTROLE/PREPARATION DES Batteries SUR UNE Machine Nouvelle

Avertissement Consultation

Mode Demploi ET Dentretien

Installation des batteries

Avant LA Mise EN Marche DE LA Machine

Sans batteries

Machine AU Travail

Mise en marche

Débloquer le volant 10, Fig. B au moyen du bouton

Arrêt de la machine

Reglage DU Phare DE Travail

Inactivite Prolongee DE LA Machine

Premiere Periode Dutilisation

Entretien

Plan Recapitulatif Dentretien Programme

Serrer le contre-écrou 2, Fig. E

Remplacement DES Brosses Laterales

Controle ET Reglage DE LA Hauteur DES Brosses Laterales

Contrôler que le corps du filtre n’a pas de déchirures

12. Déposer le séparateur intérieur poches 7, Fig. AC

Controle DE LA Hauteur ET DU Fonctionnement DES Volets

Chargement DES Batteries

Volets latéraux

Volets avant et arrière

Fonctions DE Securite

Depistage DES Pannes

Interrupteur DE Marche

BOUTON-POUSSOIR Durgence

Mise EN Decharge

Instruções DE USO Introdução

Descrição DA Máquina

Manutenção

Funções DE Segurança

Introdução

Instruções DE USO Instruções Gerais

Desempacotamento

Descrição DA Máquina

Funcionamento DA Máquina DE Varrer Terra 5200B

Convenções

Descrição

Instruções DE USO Dados Técnicos

Esquema elétrico Ver a fig. AF

Trás

Códigos de cores

VERIFICAÇÃO/CONFIGURAÇÃO DE Bateria EM UMA Máquina Nova

Fusíveis

ACESSÓRIOS/OPÇÕES

Perigo Atenção Advertência Consulta

Configuração das baterias WET ou GEL

Instalação E Definição DE Bateria WET OU GEL

Antes DA Partida DA Máquina

Baterias não fornecidas

Instruções DE USO Partida E Parada DA Máquina

Máquina EM Funcionamento

Partida da máquina

Parada da máquina

Ajuste DA LUZ DE Trabalho

Desativação Prolongada DA Máquina

Período Inicial DE USO

Máquina está pronta para retomar o trabalho

Manutenção

Tabela DE Manutenção Programada

Verificação E Regulação DA

Altura DA Vassoura Central

São fornecidas vassouras com vários tipos

Aperte a porca de aperto 2, fig. E

Instruções DE USO Verificação E Regulação DA

Altura DAS Vassouras Laterais

Os filtros de bolsa em poliéster

Ser aplicado a qualquer tipo Procedimento indicado a seguir

Quando as superfícies de filtragem já não

Forem adequadas, será necessário

Verificação DA Altura E do Funcionamento DAS Abas

Carregamento DA Bateria

Aba lateral

Funções DE Segurança

Localização DE Defeitos

Interruptor DE Consentimento DE Funcionamento

Interruptor DE Emergência

Descarte

S310215

200 BAR

Terra 5200B 146 1996

Nilfisk-Advance, Inc