PLACE THE BOILER SECTIONS

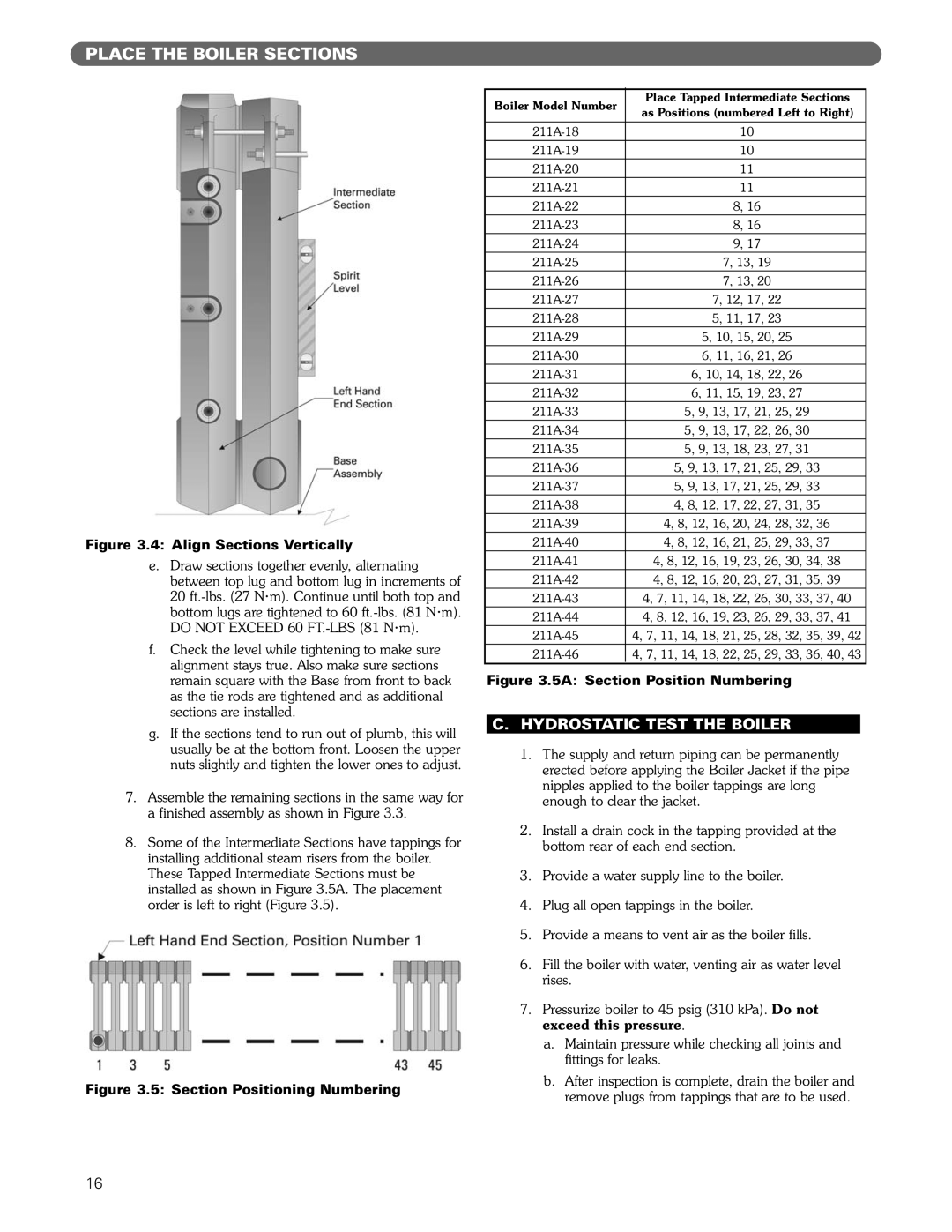

Figure 3.4: Align Sections Vertically

e.Draw sections together evenly, alternating between top lug and bottom lug in increments of

20

f.Check the level while tightening to make sure alignment stays true. Also make sure sections remain square with the Base from front to back as the tie rods are tightened and as additional sections are installed.

g.If the sections tend to run out of plumb, this will usually be at the bottom front. Loosen the upper nuts slightly and tighten the lower ones to adjust.

7.Assemble the remaining sections in the same way for a finished assembly as shown in Figure 3.3.

8.Some of the Intermediate Sections have tappings for installing additional steam risers from the boiler. These Tapped Intermediate Sections must be installed as shown in Figure 3.5A. The placement order is left to right (Figure 3.5).

Figure 3.5: Section Positioning Numbering

Boiler Model Number | Place Tapped Intermediate Sections | |

as Positions (numbered Left to Right) | ||

| ||

|

| |

10 | ||

10 | ||

11 | ||

11 | ||

8, 16 | ||

8, 16 | ||

9, 17 | ||

7, 13, 19 | ||

7, 13, 20 | ||

7, 12, 17, 22 | ||

5, 11, 17, 23 | ||

5, 10, 15, 20, 25 | ||

6, 11, 16, 21, 26 | ||

6, 10, 14, 18, 22, 26 | ||

6, 11, 15, 19, 23, 27 | ||

5, 9, 13, 17, 21, 25, 29 | ||

5, 9, 13, 17, 22, 26, 30 | ||

5, 9, 13, 18, 23, 27, 31 | ||

5, 9, 13, 17, 21, 25, 29, 33 | ||

5, 9, 13, 17, 21, 25, 29, 33 | ||

4, 8, 12, 17, 22, 27, 31, 35 | ||

4, 8, 12, 16, 20, 24, 28, 32, 36 | ||

4, 8, 12, 16, 21, 25, 29, 33, 37 | ||

4, 8, 12, 16, 19, 23, 26, 30, 34, 38 | ||

4, 8, 12, 16, 20, 23, 27, 31, 35, 39 | ||

4, 7, 11, 14, 18, 22, 26, 30, 33, 37, 40 | ||

4, 8, 12, 16, 19, 23, 26, 29, 33, 37, 41 | ||

4, 7, 11, 14, 18, 21, 25, 28, 32, 35, 39, 42 | ||

4, 7, 11, 14, 18, 22, 25, 29, 33, 36, 40, 43 |

Figure 3.5A: Section Position Numbering

C.HYDROSTATIC TEST THE BOILER

1.The supply and return piping can be permanently erected before applying the Boiler Jacket if the pipe nipples applied to the boiler tappings are long enough to clear the jacket.

2.Install a drain cock in the tapping provided at the bottom rear of each end section.

3.Provide a water supply line to the boiler.

4.Plug all open tappings in the boiler.

5.Provide a means to vent air as the boiler fills.

6.Fill the boiler with water, venting air as water level rises.

7.Pressurize boiler to 45 psig (310 kPa). Do not exceed this pressure.

a.Maintain pressure while checking all joints and fittings for leaks.

b.After inspection is complete, drain the boiler and remove plugs from tappings that are to be used.

16