PIPE THE BOILER

5. PIPE THE BOILER

A.PREPARATION

1.The boiler must be pressure tested as outlined in Chapter 3, “Place the Boiler Sections,” of this manual.

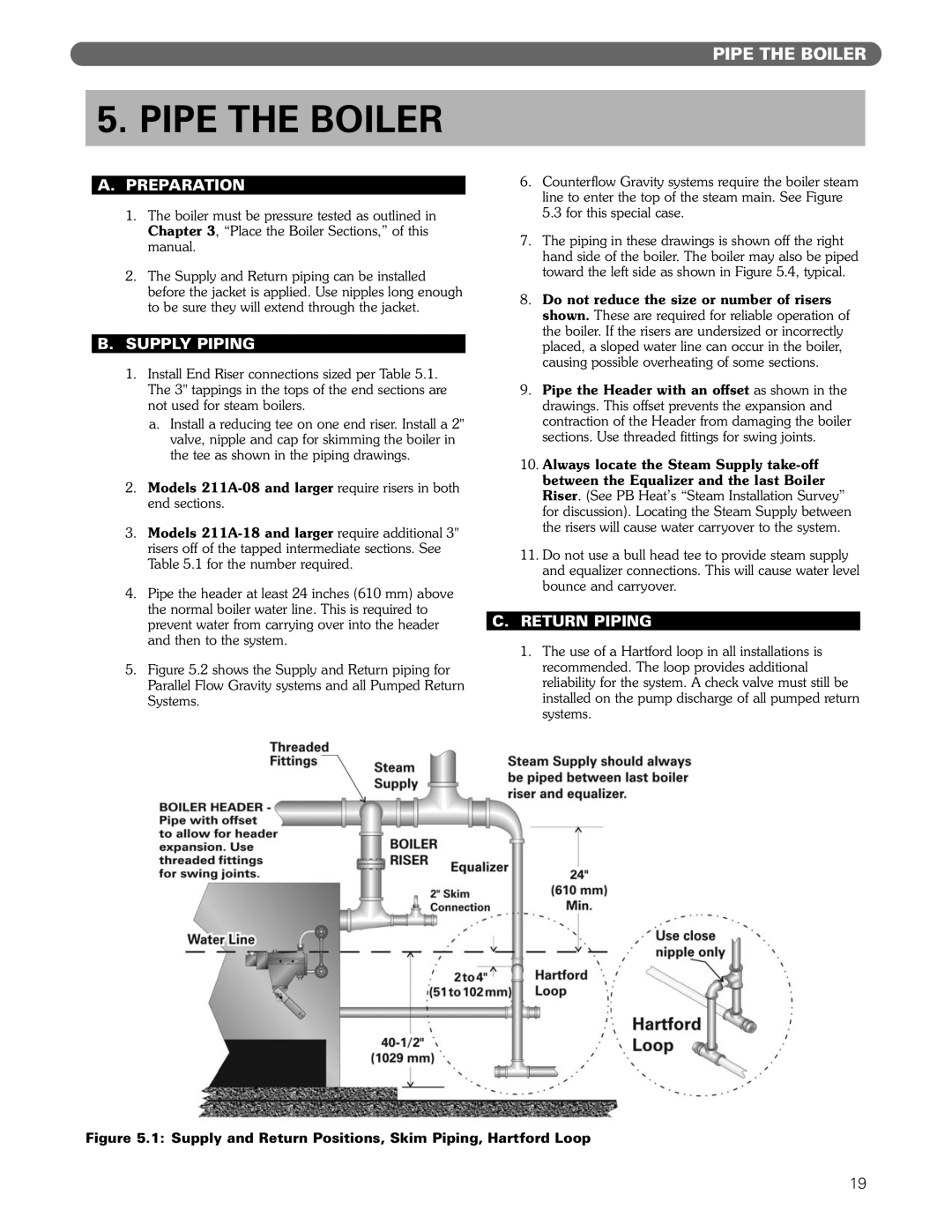

2.The Supply and Return piping can be installed before the jacket is applied. Use nipples long enough to be sure they will extend through the jacket.

B.SUPPLY PIPING

1.Install End Riser connections sized per Table 5.1. The 3" tappings in the tops of the end sections are not used for steam boilers.

a.Install a reducing tee on one end riser. Install a 2" valve, nipple and cap for skimming the boiler in the tee as shown in the piping drawings.

2.Models

3.Models

4.Pipe the header at least 24 inches (610 mm) above the normal boiler water line. This is required to prevent water from carrying over into the header and then to the system.

5.Figure 5.2 shows the Supply and Return piping for Parallel Flow Gravity systems and all Pumped Return Systems.

6.Counterflow Gravity systems require the boiler steam line to enter the top of the steam main. See Figure 5.3 for this special case.

7.The piping in these drawings is shown off the right hand side of the boiler. The boiler may also be piped toward the left side as shown in Figure 5.4, typical.

8.Do not reduce the size or number of risers shown. These are required for reliable operation of the boiler. If the risers are undersized or incorrectly placed, a sloped water line can occur in the boiler, causing possible overheating of some sections.

9.Pipe the Header with an offset as shown in the drawings. This offset prevents the expansion and contraction of the Header from damaging the boiler sections. Use threaded fittings for swing joints.

10.Always locate the Steam Supply

11.Do not use a bull head tee to provide steam supply and equalizer connections. This will cause water level bounce and carryover.

C.RETURN PIPING

1.The use of a Hartford loop in all installations is recommended. The loop provides additional reliability for the system. A check valve must still be installed on the pump discharge of all pumped return systems.

Figure 5.1: Supply and Return Positions, Skim Piping, Hartford Loop

19