PIPE THE BOILER

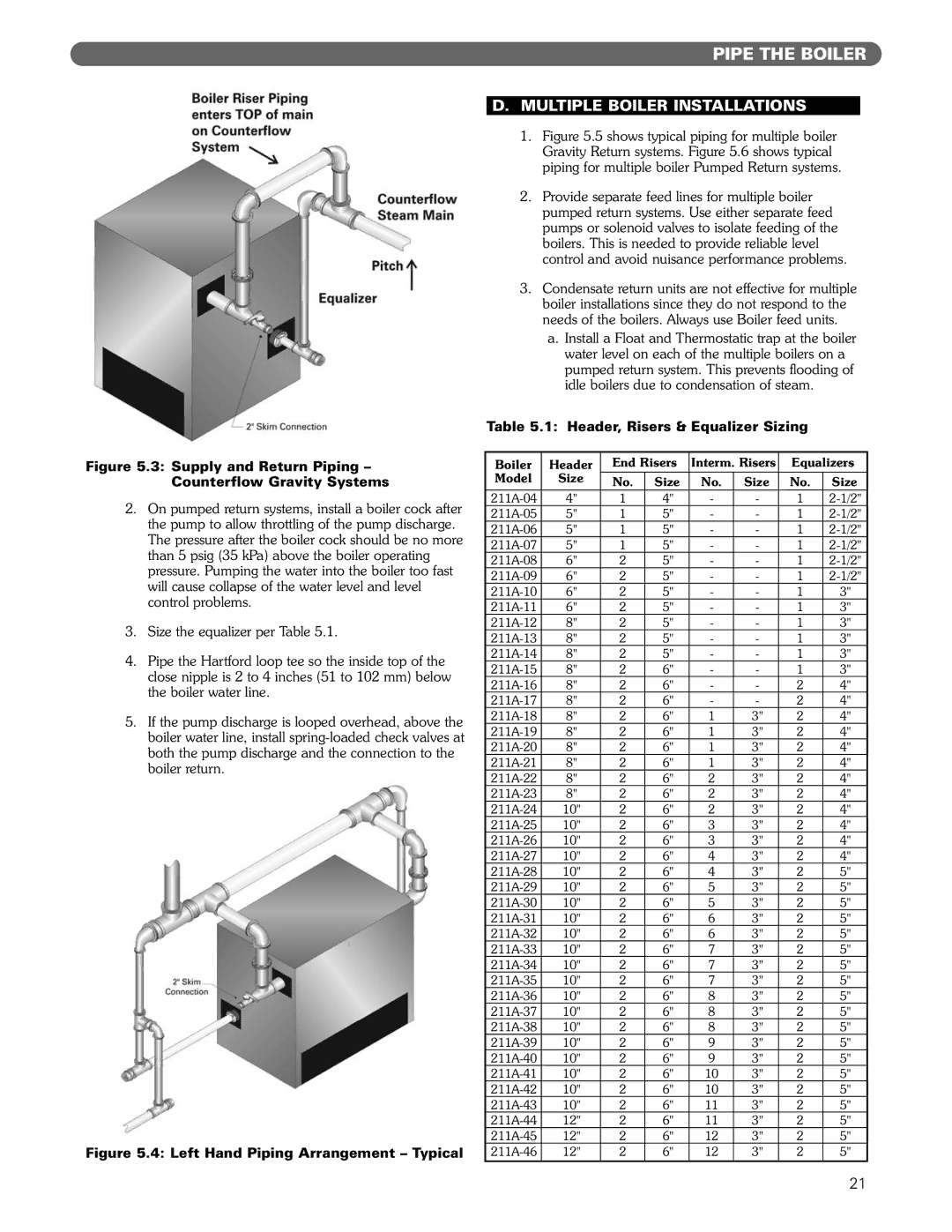

Figure 5.3: Supply and Return Piping – Counterflow Gravity Systems

2.On pumped return systems, install a boiler cock after the pump to allow throttling of the pump discharge. The pressure after the boiler cock should be no more than 5 psig (35 kPa) above the boiler operating pressure. Pumping the water into the boiler too fast will cause collapse of the water level and level control problems.

3.Size the equalizer per Table 5.1.

4.Pipe the Hartford loop tee so the inside top of the close nipple is 2 to 4 inches (51 to 102 mm) below the boiler water line.

5.If the pump discharge is looped overhead, above the boiler water line, install

Figure 5.4: Left Hand Piping Arrangement – Typical

D.MULTIPLE BOILER INSTALLATIONS

1.Figure 5.5 shows typical piping for multiple boiler Gravity Return systems. Figure 5.6 shows typical piping for multiple boiler Pumped Return systems.

2.Provide separate feed lines for multiple boiler pumped return systems. Use either separate feed pumps or solenoid valves to isolate feeding of the boilers. This is needed to provide reliable level control and avoid nuisance performance problems.

3.Condensate return units are not effective for multiple boiler installations since they do not respond to the needs of the boilers. Always use Boiler feed units.

a.Install a Float and Thermostatic trap at the boiler water level on each of the multiple boilers on a pumped return system. This prevents flooding of idle boilers due to condensation of steam.

Table 5.1: Header, Risers & Equalizer Sizing

Boiler | Header | End Risers | Interm. Risers | Equalizers | |||

Model | Size | No. | Size | No. | Size | No. | Size |

4" | 1 | 4" | - | - | 1 | ||

5" | 1 | 5" | - | - | 1 | ||

5" | 1 | 5" | - | - | 1 | ||

5" | 1 | 5" | - | - | 1 | ||

6" | 2 | 5" | - | - | 1 | ||

6" | 2 | 5" | - | - | 1 | ||

6" | 2 | 5" | - | - | 1 | 3" | |

6" | 2 | 5" | - | - | 1 | 3" | |

8" | 2 | 5" | - | - | 1 | 3" | |

8" | 2 | 5" | - | - | 1 | 3" | |

8" | 2 | 5" | - | - | 1 | 3" | |

8" | 2 | 6" | - | - | 1 | 3" | |

8" | 2 | 6" | - | - | 2 | 4" | |

8" | 2 | 6" | - | - | 2 | 4" | |

8" | 2 | 6" | 1 | 3" | 2 | 4" | |

8" | 2 | 6" | 1 | 3" | 2 | 4" | |

8" | 2 | 6" | 1 | 3" | 2 | 4" | |

8" | 2 | 6" | 1 | 3" | 2 | 4" | |

8" | 2 | 6" | 2 | 3" | 2 | 4" | |

8" | 2 | 6" | 2 | 3" | 2 | 4" | |

10" | 2 | 6" | 2 | 3" | 2 | 4" | |

10" | 2 | 6" | 3 | 3" | 2 | 4" | |

10" | 2 | 6" | 3 | 3" | 2 | 4" | |

10" | 2 | 6" | 4 | 3" | 2 | 4" | |

10" | 2 | 6" | 4 | 3" | 2 | 5" | |

10" | 2 | 6" | 5 | 3" | 2 | 5" | |

10" | 2 | 6" | 5 | 3" | 2 | 5" | |

10" | 2 | 6" | 6 | 3" | 2 | 5" | |

10" | 2 | 6" | 6 | 3" | 2 | 5" | |

10" | 2 | 6" | 7 | 3" | 2 | 5" | |

10" | 2 | 6" | 7 | 3" | 2 | 5" | |

10" | 2 | 6" | 7 | 3" | 2 | 5" | |

10" | 2 | 6" | 8 | 3" | 2 | 5" | |

10" | 2 | 6" | 8 | 3" | 2 | 5" | |

10" | 2 | 6" | 8 | 3" | 2 | 5" | |

10" | 2 | 6" | 9 | 3" | 2 | 5" | |

10" | 2 | 6" | 9 | 3" | 2 | 5" | |

10" | 2 | 6" | 10 | 3" | 2 | 5" | |

10" | 2 | 6" | 10 | 3" | 2 | 5" | |

10" | 2 | 6" | 11 | 3" | 2 | 5" | |

12" | 2 | 6" | 11 | 3" | 2 | 5" | |

12" | 2 | 6" | 12 | 3" | 2 | 5" | |

12" | 2 | 6" | 12 | 3" | 2 | 5" | |

|

|

|

|

|

|

|

|

21