PREINSTALLATION

2.Required Combustion Air Volume: The total required volume of indoor air is to be the sum of the required volumes for all appliances located within the space.

Rooms communicating directly with the space in which the appliances are installed and through combustion air openings sized as indicated in Subsection 3 are considered part of the required volume. The required volume of indoor air is to be determined by one of two methods.

a.Standard Method: The minimum required volume of indoor air (room volume) shall be 50 cubic feet per 1000 BTU/Hr (4.8 m3/kW). This method is to be used if the air infiltration rate is unknown or if the rate of air infiltration is known to be greater than 0.6 air changes per hour. As an option, this method may be used if the air infiltration rate is known to be between 0.6 and 0.4 air changes per hour. If the air infiltration rate is known to be below 0.4 then the Known Air Infiltration Rate Method must be used. If the building in which this appliance is to be installed is unusually tight, PB Heat recommends that the air infiltration rate be determined.

b.Known Air Infiltration Rate Method: Where the air infiltration rate of a structure is known, the minimum required volume of indoor air for appliances other than fan assisted and for the Series 211A Boiler shall be determined as follows:

| 21 ft3 | ⎛ | Iother | ⎝ | |

Required Volumeother = |

| ⎝⎜ |

|

| ⎜ |

ACH | 1000Btu/hr |

| |||

|

|

|

|

| ⎛ |

where:

Iother = Input of appliances other than fan assisted in Btu/hr

ACH = air change per hour (percent of the volume of the space exchanged per hour, expressed as a decimal)

For fan assisted appliances, calculate the required volume of air using the following equation:

Required Volumefan = | 15 ft3 | ⎛ | Ifan |

| ⎝ |

| ⎜ |

|

| ⎜ | |

ACH | Btu | / | |||

| ⎝ | 1000 |

| ||

|

|

|

| hr | |

|

|

|

|

| ⎛ |

Ifan = Input of the fan assisted appliances in Btu/hr

Note: These calculations are not to be used for infiltration rates greater than 0.60 ACH.

3.Indoor Air Opening Size and Location: Openings connecting indoor spaces shall be sized and located as follows:

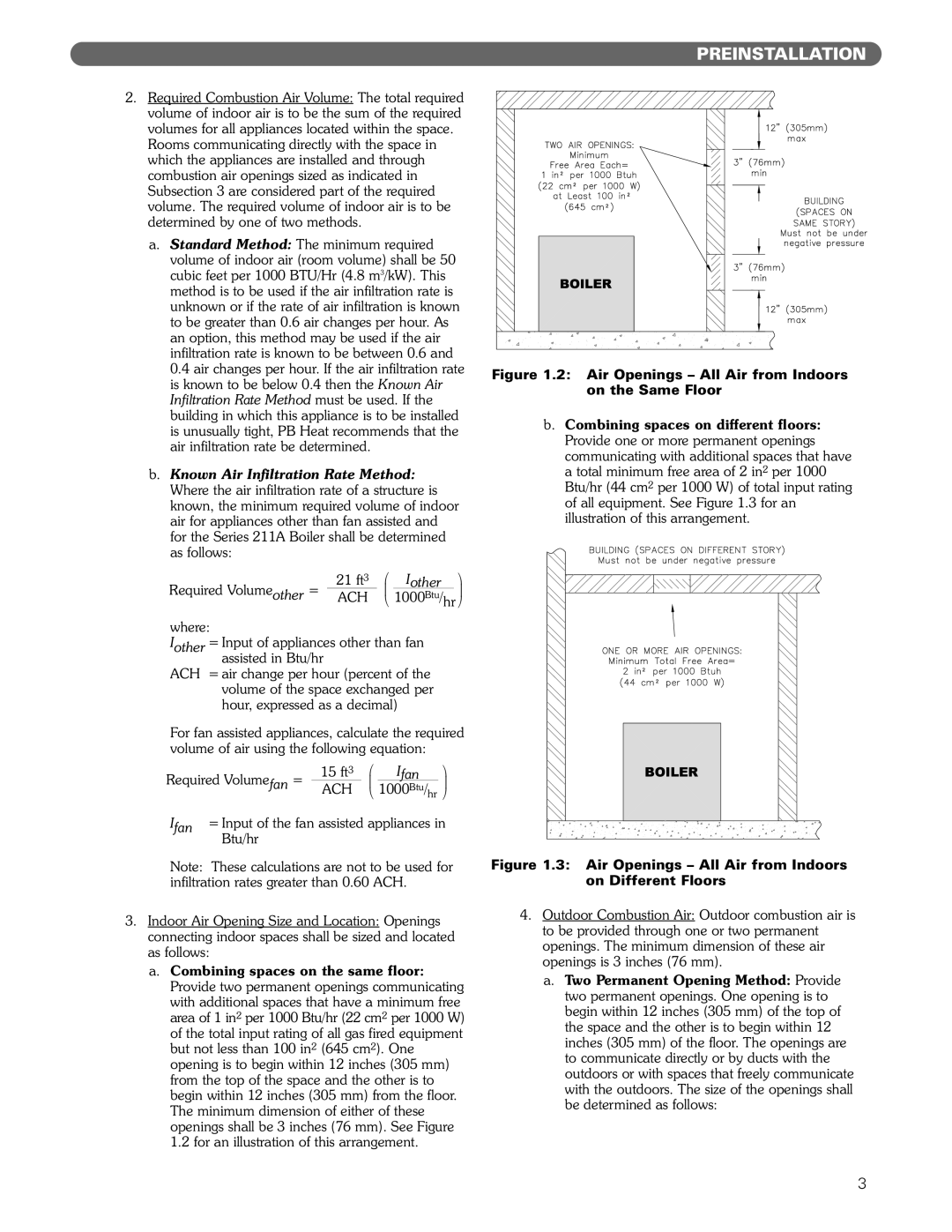

a.Combining spaces on the same floor: Provide two permanent openings communicating with additional spaces that have a minimum free area of 1 in2 per 1000 Btu/hr (22 cm2 per 1000 W) of the total input rating of all gas fired equipment but not less than 100 in2 (645 cm2). One opening is to begin within 12 inches (305 mm) from the top of the space and the other is to begin within 12 inches (305 mm) from the floor. The minimum dimension of either of these openings shall be 3 inches (76 mm). See Figure 1.2 for an illustration of this arrangement.

Figure 1.2: Air Openings – All Air from Indoors on the Same Floor

b.Combining spaces on different floors: Provide one or more permanent openings communicating with additional spaces that have a total minimum free area of 2 in2 per 1000 Btu/hr (44 cm2 per 1000 W) of total input rating of all equipment. See Figure 1.3 for an illustration of this arrangement.

Figure 1.3: Air Openings – All Air from Indoors on Different Floors

4.Outdoor Combustion Air: Outdoor combustion air is to be provided through one or two permanent openings. The minimum dimension of these air openings is 3 inches (76 mm).

a.Two Permanent Opening Method: Provide two permanent openings. One opening is to begin within 12 inches (305 mm) of the top of the space and the other is to begin within 12 inches (305 mm) of the floor. The openings are to communicate directly or by ducts with the outdoors or with spaces that freely communicate with the outdoors. The size of the openings shall be determined as follows:

3