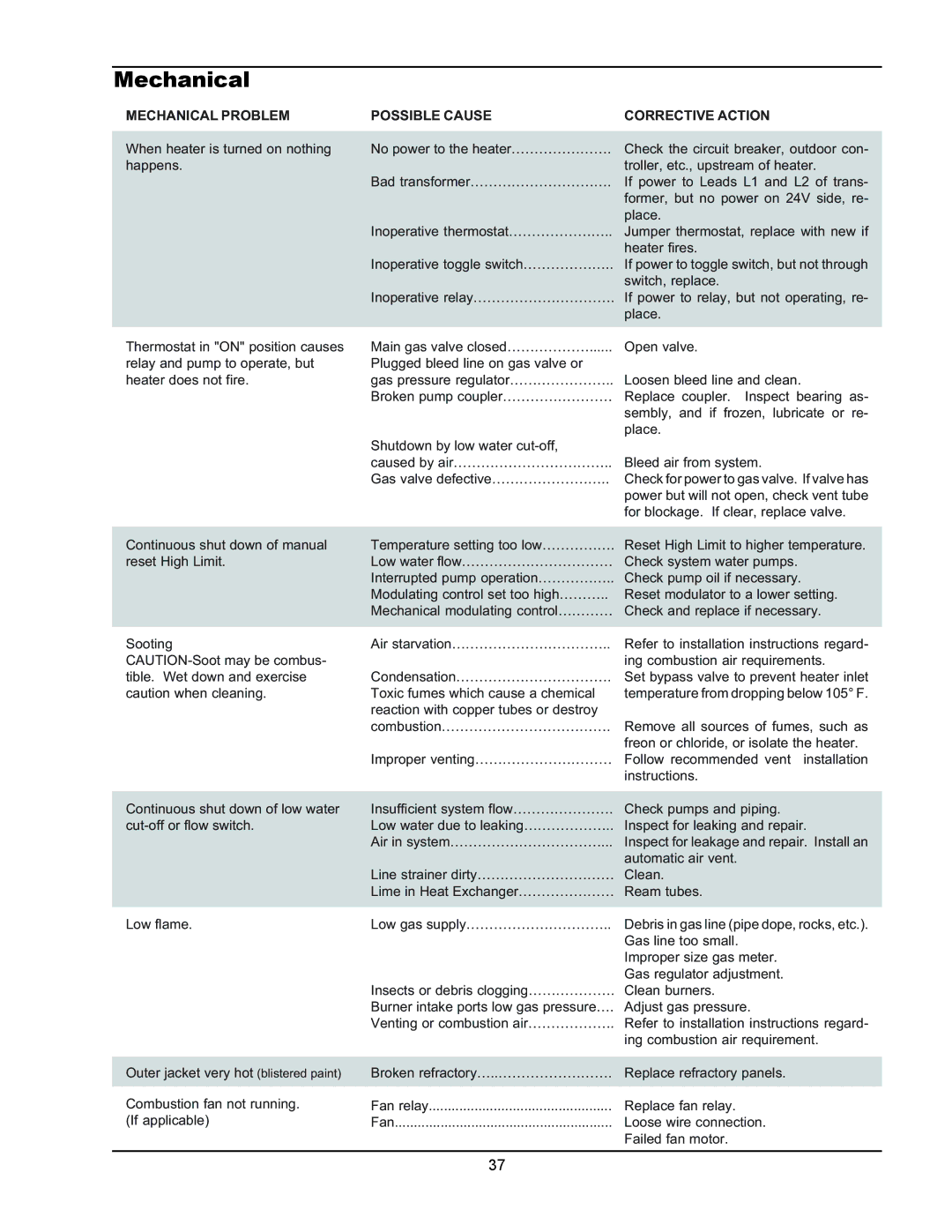

Mechanical

MECHANICAL PROBLEM | POSSIBLE CAUSE | CORRECTIVE ACTION |

When heater is turned on nothing | No power to the heater…………………. | Check the circuit breaker, outdoor con- |

happens. |

| troller, etc., upstream of heater. |

| Bad transformer…………………………. | If power to Leads L1 and L2 of trans- |

|

| former, but no power on 24V side, re- |

|

| place. |

| Inoperative thermostat………………….. | Jumper thermostat, replace with new if |

|

| heater fires. |

| Inoperative toggle switch……………….. | If power to toggle switch, but not through |

|

| switch, replace. |

Inoperative relay…………………………. If power to relay, but not operating, re-

place.

Thermostat in "ON" position causes relay and pump to operate, but heater does not fire.

Main gas valve closed………………...... Open valve.

Plugged bleed line on gas valve or

gas pressure regulator………………….. Loosen bleed line and clean.

Broken pump coupler…………………… Replace coupler. Inspect bearing as-

sembly, and if frozen, lubricate or re- place.

Shutdown by low water

caused by air…………………………….. Bleed air from system.

Gas valve defective…………………….. Check for power to gas valve. If valve has

power but will not open, check vent tube for blockage. If clear, replace valve.

Continuous shut down of manual | Temperature setting too low……………. | Reset High Limit to higher temperature. |

reset High Limit. | Low water flow…………………………… | Check system water pumps. |

| Interrupted pump operation…………….. | Check pump oil if necessary. |

| Modulating control set too high……….. | Reset modulator to a lower setting. |

| Mechanical modulating control………… | Check and replace if necessary. |

|

|

|

Sooting | Air starvation…………………………….. |

| |

tible. Wet down and exercise | Condensation……………………………. |

caution when cleaning. | Toxic fumes which cause a chemical |

| reaction with copper tubes or destroy |

| combustion………………………………. |

| Improper venting………………………… |

Refer to installation instructions regard- ing combustion air requirements.

Set bypass valve to prevent heater inlet temperature from dropping below 105° F.

Remove all sources of fumes, such as freon or chloride, or isolate the heater. Follow recommended vent installation instructions.

Continuous shut down of low water | Insufficient system flow…………………. | Check pumps and piping. |

Low water due to leaking……………….. | Inspect for leaking and repair. | |

| Air in system……………………………... | Inspect for leakage and repair. Install an |

|

| automatic air vent. |

| Line strainer dirty………………………… | Clean. |

| Lime in Heat Exchanger………………… | Ream tubes. |

|

|

|

Low flame.

Outer jacket very hot (blistered paint)

Combustion fan not running. (If applicable)

Low gas supply………………………….. Debris in gas line (pipe dope, rocks, etc.).

Gas line too small. Improper size gas meter. Gas regulator adjustment.

Insects or debris clogging………………. Clean burners.

Burner intake ports low gas pressure…. Adjust gas pressure.

Venting or combustion air………………. Refer to installation instructions regard-

| ing combustion air requirement. |

Broken refractory…..……………………. | Replace refractory panels. |

Fan relay | Replace fan relay. |

Fan | Loose wire connection. |

| Failed fan motor. |

37