INSTALLATION

VENTING ARRANGEMENTS

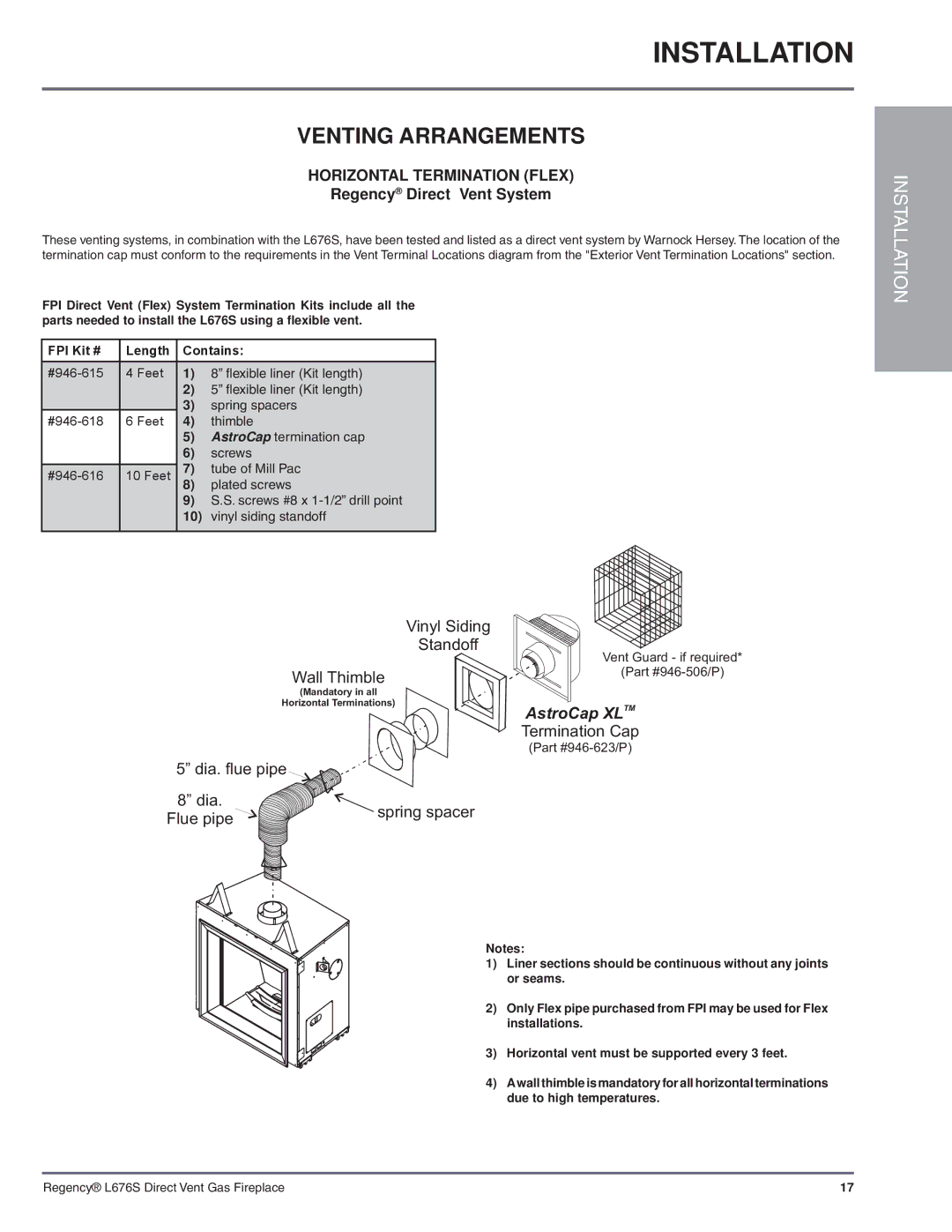

HORIZONTAL TERMINATION (FLEX)

Regency® Direct Vent System

These venting systems, in combination with the L676S, have been tested and listed as a direct vent system by Warnock Hersey. The location of the termination cap must conform to the requirements in the Vent Terminal Locations diagram from the "Exterior Vent Termination Locations" section.

FPI Direct Vent (Flex) System Termination Kits include all the parts needed to install the L676S using a flexible vent.

FPI Kit # | Length | Contains: | |

4 Feet | 1) | 8” flexible liner (Kit length) | |

|

| 2) | 5” flexible liner (Kit length) |

|

| 3) | spring spacers |

6 Feet | 4) | thimble | |

|

| 5) | AstroCap termination cap |

|

| 6) | screws |

|

| 7) | tube of Mill Pac |

10 Feet | |||

|

| 8) | plated screws |

|

| 9) | S.S. screws #8 x |

|

| 10) | vinyl siding standoff |

|

|

|

|

INSTALLATION

Vinyl Siding

Standoff

Wall Thimble

Vent Guard - if required*

(Part

| (Mandatory in all | |

| Horizontal Terminations) | |

| AstroCap XLTM | |

| Termination Cap | |

| (Part | |

5” dia. flue pipe | ||

8” dia. | spring spacer | |

Flue pipe | ||

| ||

Notes:

1) Liner sections should be continuous without any joints or seams.

2) Only Flex pipe purchased from FPI may be used for Flex installations.

3)Horizontal vent must be supported every 3 feet.

4)A wall thimble is mandatory for all horizontal terminations due to high temperatures.

Regency® L676S Direct Vent Gas Fireplace | 17 |