INSTALLATION

HORIZONTAL

INSTALLATIONS

1)Set the unit in its desired location. Check to determine if wall studs or roof rafters are in the way when the venting system is attached. If this is the case, you may want to adjust the location of the unit. Rough in the gas preferably on the right side of the unit and the electrical (junction block is on the left side) on the left.

2)Direct Vent pipe and fittings are designed with special

3)Put a bead of silicone inside the outer section of the adapter and a bead of Stove Mate on the inner collar. Slip the adapter over the existing inner and outer flue collar and fasten to the outer collar only with the 3 supplied screws (drilling pilot holes will make this easier). Level the fireplace and fasten it to the framing using nails or screws through the nailing strips.

4)Assemble the desired combination of pipe and elbows to the appliance adaptor and

Note:

a)

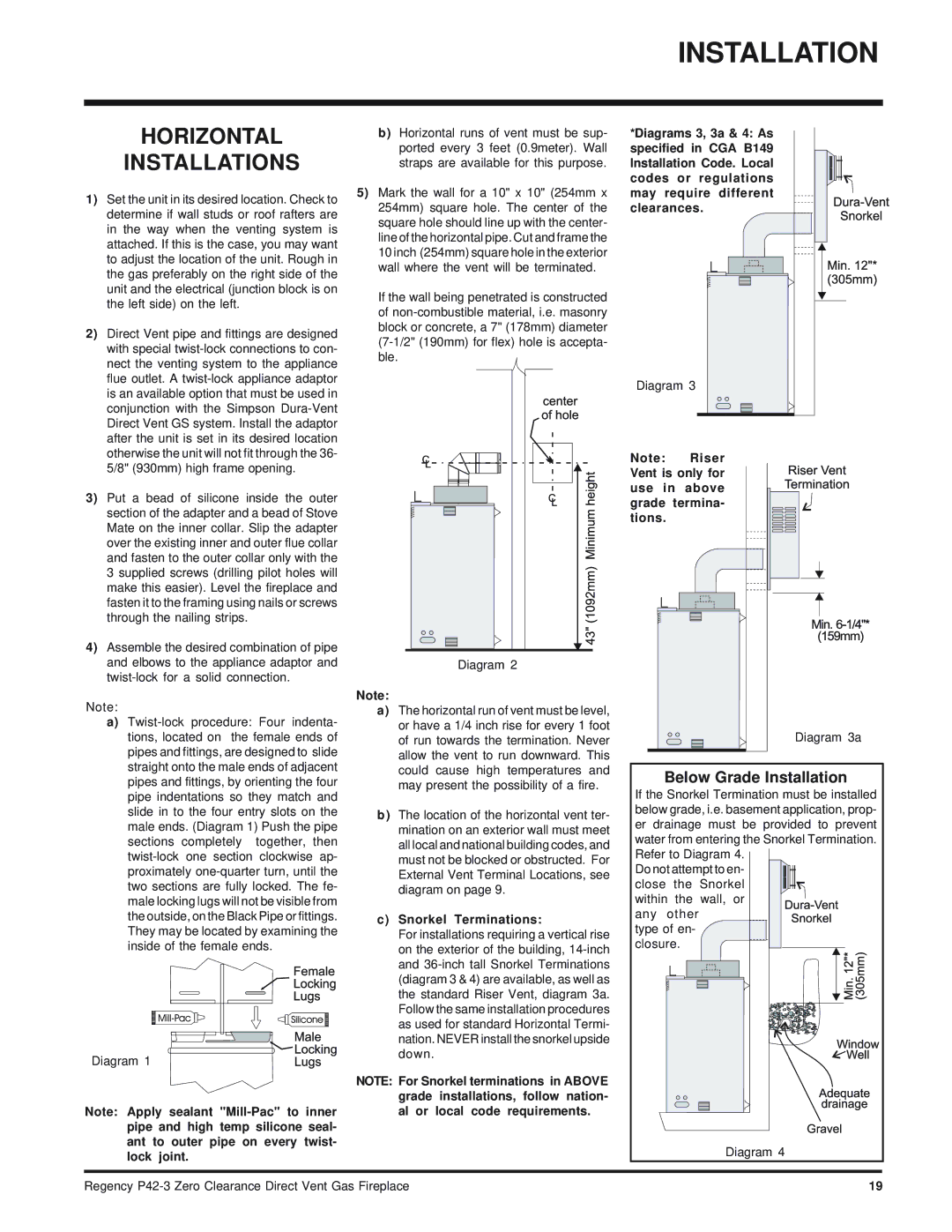

Diagram 1

Note: Apply sealant

b)Horizontal runs of vent must be sup- ported every 3 feet (0.9meter). Wall straps are available for this purpose.

5)Mark the wall for a 10" x 10" (254mm x 254mm) square hole. The center of the square hole should line up with the center- line of the horizontal pipe. Cut and frame the 10 inch (254mm) square hole in the exterior wall where the vent will be terminated.

If the wall being penetrated is constructed of

Diagram 2

Note:

a)The horizontal run of vent must be level, or have a 1/4 inch rise for every 1 foot of run towards the termination. Never allow the vent to run downward. This could cause high temperatures and may present the possibility of a fire.

b)The location of the horizontal vent ter- mination on an exterior wall must meet all local and national building codes, and must not be blocked or obstructed. For External Vent Terminal Locations, see diagram on page 9.

c)Snorkel Terminations:

For installations requiring a vertical rise on the exterior of the building,

NOTE: For Snorkel terminations in ABOVE grade installations, follow nation- al or local code requirements.

*Diagrams 3, 3a & 4: As specified in CGA B149 Installation Code. Local codes or regulations may require different clearances.

Diagram 3

Note: Riser Vent is only for use in above grade termina- tions.

Diagram 3a

Below Grade Installation

If the Snorkel Termination must be installed below grade, i.e. basement application, prop- er drainage must be provided to prevent water from entering the Snorkel Termination. Refer to Diagram 4.

Do not attempt to en- close the Snorkel within the wall, or

any other type of en-

closure.

Diagram 4

Regency | 19 |