Basic Saw Operations (continued)

Resawing

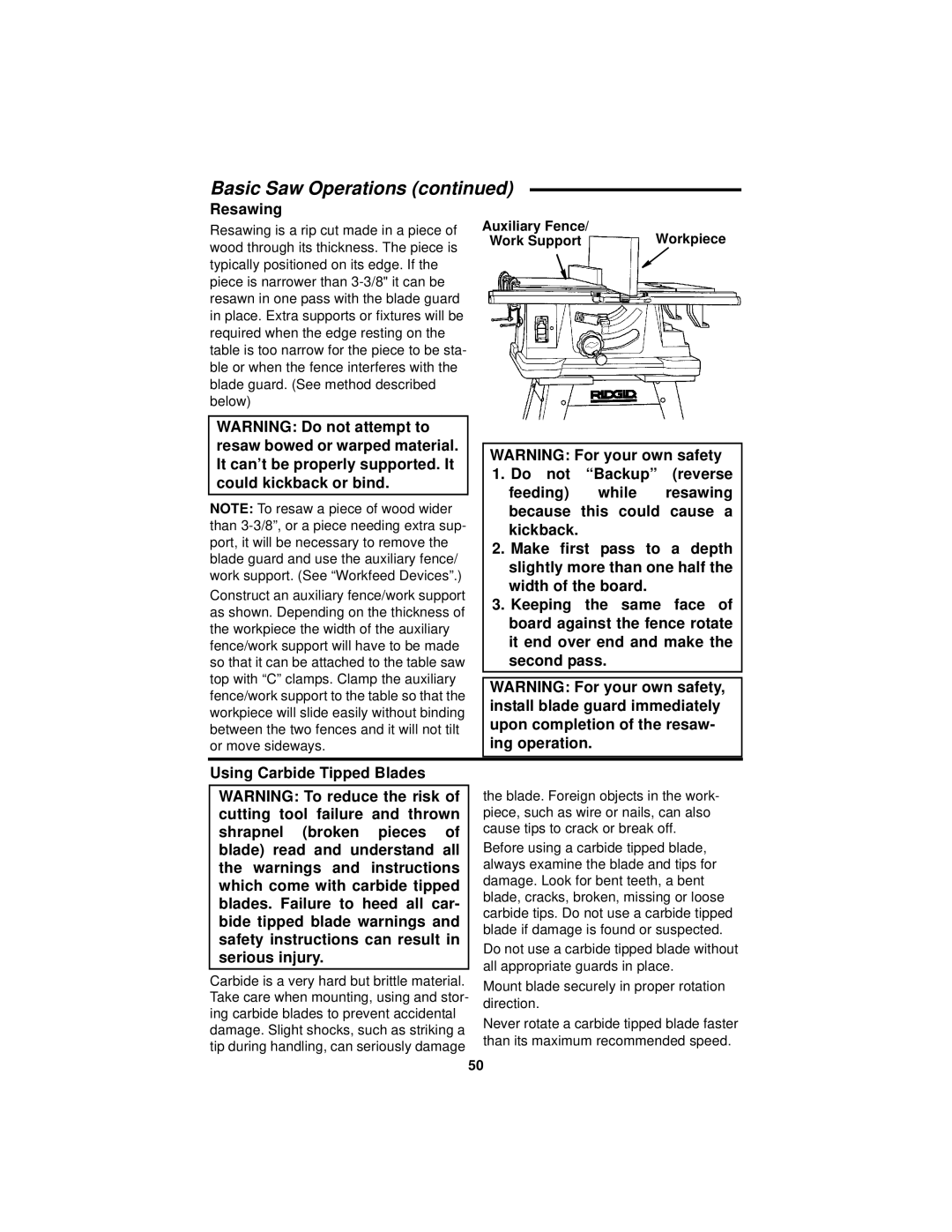

Resawing is a rip cut made in a piece of wood through its thickness. The piece is typically positioned on its edge. If the piece is narrower than

Auxiliary Fence/ | Workpiece |

Work Support |

WARNING: Do not attempt to |

|

|

|

| |

resaw bowed or warped material. |

|

|

|

| |

WARNING: For your own safety | |||||

It can’t be properly supported. It |

| ||||

| 1. Do not | “Backup” | (reverse | ||

could kickback or bind. |

| ||||

| feeding) | while | resawing | ||

|

| ||||

NOTE: To resaw a piece of wood wider | |||||

because this could cause a | |||||

than | kickback. |

|

| ||

port, it will be necessary to remove the | 2. Make first pass to | a depth | |||

blade guard and use the auxiliary fence/ | |||||

slightly more than one half the | |||||

work support. (See “Workfeed Devices”.) | |||||

width of the board. |

| ||||

Construct an auxiliary fence/work support |

| ||||

3. Keeping | the same | face of | |||

as shown. Depending on the thickness of | |||||

board against the fence rotate | |||||

the workpiece the width of the auxiliary | |||||

it end over end and make the | |||||

fence/work support will have to be made | |||||

so that it can be attached to the table saw | second pass. |

| |||

top with “C” clamps. Clamp the auxiliary |

|

|

| ||

WARNING: For your own safety, | |||||

fence/work support to the table so that the | |||||

install blade guard immediately | |||||

workpiece will slide easily without binding | |||||

upon completion of the resaw- | |||||

between the two fences and it will not tilt | |||||

ing operation. |

| ||||

or move sideways. |

| ||||

Using Carbide Tipped Blades

WARNING: To reduce the risk of cutting tool failure and thrown shrapnel (broken pieces of blade) read and understand all the warnings and instructions which come with carbide tipped blades. Failure to heed all car- bide tipped blade warnings and safety instructions can result in serious injury.

Carbide is a very hard but brittle material. Take care when mounting, using and stor- ing carbide blades to prevent accidental damage. Slight shocks, such as striking a tip during handling, can seriously damage

the blade. Foreign objects in the work- piece, such as wire or nails, can also cause tips to crack or break off.

Before using a carbide tipped blade, always examine the blade and tips for damage. Look for bent teeth, a bent blade, cracks, broken, missing or loose carbide tips. Do not use a carbide tipped blade if damage is found or suspected. Do not use a carbide tipped blade without all appropriate guards in place.

Mount blade securely in proper rotation direction.

Never rotate a carbide tipped blade faster than its maximum recommended speed.

50