Saab 9-5, Model Year

Introduction

Instrument panel

Exterior

Interior

Engine compartment

Battery

Even with Advanced AIR Bags

Examples of symbols that can be found in your car

This page has been left blank

Safety

Seats Head restraint Safety belts Child safety Airbag

Safety belts

Safety belt reminder

More upright position Only one person per safety belt

Correct position for safety belt

Better protection when the seat is in a

Is advisable to remove thick items of clothing

Front safety belts

Belt height adjustment

To fasten the belt

Safety belt pretensioners

Safety belt use during pregnancy

Safety belt, rear seat

Safety belt, rear seat Securing an item on the rear seat

Safety

Side airbags

Seats

Height

See

Backrest rake angle

Legroom adjustment

Lumbar support

Memory driver’s seat

Head restraint

Rear-seat head restraints

Protect children from getting trapped in the trunk of a car

Child safety

Car safety tips

For Trunk Release Handle information see page 48

Lower Anchorages and Top Tethers for Children Latch System

Rigid 2-point lower attachment with top tether

Tions

Location of lower anchors

Semi-rigid 2-point lower attachment with top tether

Securing a Child Restraint

Designed for the Latch System

Sedan

Child tether anchorages in parcel shelf, Saab 9-5 Sedan

Lockable latch plate

Locking the lap belt

Installation of rear facing child restraints

Airbag

Inflated airbag driver side

Passenger airbag and driver’s airbag both

Inflated

Airbag system with belt pretensioners

Generator that inflates Airbag

Front passenger seat

Airbag

Passenger Airbag Status Indicator, Canada

Passenger Airbag Status Indicator

Passenger Sensing System

Safety

Safety

Side airbags

Side airbag inflated

Airbag warning light

Side airbag components

What Will You See After an Airbag Inflates?

Airbag servicing

Scrapping or working on airbags and belt pretensioners

What won’t trigger the front airbags?

Frequently asked questions on function of airbags

When do the front airbags inflate?

How loud is the inflation?

Adding Equipment to Your Airbag-Equipped Vehicle

What should I do if the Airbag warning light comes on?

This page has been left empty

Doors Central locking Car alarm

Security

Central locking

Key / Remote control

Doors

Door handles

Locking/unlocking the car

Key / Remote control

Switch for operation of central locking

Remote locking

Unlocking by key

If remote unlocking should fail to work

Locking by key

Locking/unlocking by key

Child safety lock on rear doors Trunk lid switch

Child safety locks

If small children ride in the rear seats,

Unlocking

Trunk Release Handle

Tailgate, 9-5 SportCombi

Locking

Electronic starting interlock immobilizer

Changing the key battery

Remote control battery low. Replace battery

Reprogramming lock system functions

Car alarm

Remote control

Key not accepted. Contact service

Activating the car alarm

If a fault is detected e.g. in the transmitter

Button

Alarm signals

Panic-function

Low. Replace battery

Remote control battery

Overview of functions

Contact service

Overview of LED signals and SID messages

Status LED signal

SID message Reason/action Theft protection failure

Security

This page has been left blank

Instruments and controls

Shown, Canada similar

Indicator and warning lights

Main instrument panel

Brake warning light

Headlight and parking light indicator

Airbag warning light

Indicator, rear fog light

This light shows when the headlights are on high beam see

ESP system, indicator

Autochecking of lights, main instrument panel

Reset button

Instruments

Tachometer

Speedometer Fuel gauge Temperature gauge

Speedometer shown

Pressure gauge

Coolant level low. Refill

Selector lever indication

Frost warning

Outdoor temperature

Saab Information Display SID

SID, buttons and display

Dist

Alarm

Entering values for the functions

Activating speed warning

Select Speed Ø

Resetting values

Using Dist. as a trip meter

Average fuel consumption, Fuel Ø

Check messages

Selecting units and language

Units and language versions

SID has four sets of units

When the lamps are on, the mist will eventually disappear

Switches

Light switches

High/low beam

Rear fog light

Courtesy Headlight Feature

Rear fog light

Instrument illumination

Turn signal and lane change indicators

Turn signal and lane change indicators

Instrument illumination

Reversing lights

Front fog lights

Hazard warning lights

Hazard warning lights

Wipers and washers

Control for setting wiper delay

Headlight washers

Rear-window wiper SportCombi

Rear-window wiper

Automatic climate Control ACC

ACC panel

Panel vents

Panel vent

Air vent at rear side window

Temperature control

MAX cooling, blue indicator

MAX heat, red indication

Functions

Floor vents and rear side windows

Air distribution

Defroster and floor vents

Floor and panel vents

Starting in cold weather

Panel and center rear vent

Starting in hot weather

Adaptation of ACC

Useful tips

Troubleshooting and care, see

Calibration

Condensation water

Ventilated front seats

Heated front seats

Heated rear seat cushion

This page has been left blank

Saab 9-5 Audio System

Safety first

Saab 9-5 Audio System

Steering wheel controls

Audio settings

Switching the audio system On/Off

Audio system will be switched off

Audio system will come on

Radio

Tuning a station

Storing presets

Selecting a radio station

Rolling advertisements

Number of pages with preset stations

Radio Data System RDS

Radio text

Remove an Xmtm 3 category

Xmtm 3 Satellite Radio Service

Finding a Xmtm 3 station

Repeat the steps to remove more cate- gories

Restore removed Xmtm 3 categories

XM Categories

XM TM 3 Radio Messages

Radio Display Message Condition Action Required

Dealer

Fault. Consult with your Saab dealer

Not Found

XM Radion ID Radio ID label channel

CD player

Loading several CDs

CD changer

Loading a CD

Removing a CD

Selecting/changing CD

Selecting/changing CD

Random playback from all CDs

Loading MP3 discs

MP3 player

Activating the MP3 player

Removing MP3 discs

Random playback of MP3 files

Selecting/changing MP3 folder

Rapid playing an MP3 file

Playback order

Song title, artist name, etc

Connecting and activating a portable player

Portable player

AUX input

Cars without CD changer

Setting time and date

General functions

Cars with CD changer

Speed dependent volume compensation

Speed dependent volume compensation

Sound system

Harman/kardon Sound System

Tone controls

Technical data

Power output

Radio module

Multipath propagation

Antennas

Diversity antenna

Cross modulation

Shadow effect

Radio waves, FM/AM

Sources of FM interference

Sources of AM interference

Error code Possible cause

Error codes

Security lock

128

Adjustment 114 Electric windows 115

116

Trunk 129

To adjust the steering wheel

Steering wheel adjustment

Horn

To open

Electric windows

To close

Rearview mirrors

Child safety rear windows ON/OFF

Switch for rear side window

Door mirrors

Button for angling passenger’s mirror down when reversing

Adjusting the door mirrors

Adjusting switch is on the driver’s door

Door mirror folded

Rearview mirror

Rearview mirror

Buttons for garage opener and compass

Programming

Antenna wire is attached to the motor-head unit

Preparations for first-time programming

Turn the ignition on

Reprogramming a single button

Gate Operator / Canadian Programming

Erasing the three buttons

Mirrors

Rearview auto-dimming

Opening a garage door

Changing zones

Compass

Compass zones in Canada

Compass zones in US

Moonroof control

Moonroof

Dren playing Person operating the electric

Their head, hands or fingers

Manual operation of moonroof

Interior lighting

Emergency operation of moonroof

Rotate counterclockwise to close moonroof

Luggage-compartment lighting

Sun visors

Sun visor

Glove compartment

Power Outlet

Sliding cover in glove compartment to admit cold air

Interior equipment and trunk 127

Cup holder in rear armrest 3 Press the edge to open/close

Cup holders

Cup holder in fascia

Cup holder in center console

Trunk

Folding the rear seat, 9-5 Sedan

Outer safety belt hooked onto courtesy handle

Interior equipment and trunk 130

Trunk pass-through hatch

Tie Downs

Folding the rear seat, 9-5 SportCombi

Safety belt located in its belt clip

Opening handle on the right-hand side

Extend the parcel shelf as follows

Parcel shelf, 9-5 SportCombi

Fold the parcel shelf as follows

Alternative location of the parcel shelf if this is removed

Interior equipment and trunk 134

Folding the narrow section of the backrest

Load anchoring

Driving with the trunk lid/tailgate open

Example of cargo anchoring

Cargo tie down eye 3 mounted on the lon- gitudinal rails

Elastic cargo net for lighter objects

Cargo net

Cover over the fixing point for the cargo net

Storage tray 3 under luggage compartment floor SportCombi

Starting and driving

OFF position

Ignition switch

Lock position

On position

If the car does not start

When starting the engine Sit down in the driver’s seat

Starting the engine

If the text

Cars with automatic transmission

Limp-home mode

Useful tips on cold climate starting

Important considerations for driving

Important considerations with catalytic converters

Oxygen-sensor-controlled injection system

Refueling

Refueling

When refueling, hang the filler cap inside the fuel door

Filler cap

Filling a portable fuel container

Fuel Gasoline Engine

Additives

Fuels in Foreign Countries

Wearing in new brake pads

Engine Break-In Period

Gear changing

Manual transmission

Towing of cars with manual transmission, see

Towing

Automatic transmission

Selector lever

Manual mode Sentronic see Sport mode

Selector-lever indicator on main instru- ment panel

Normal mode

Detent positions for selector movement

Kick-down

Lock-up function Park Brake Shift Lock

Shift Lock override

Overheated transmission fluid

Gearbox too hot. Make a safe stop

Descending hills

Driving on hilly roads with a heavy load

Towing of cars with automatic transmission, see

Sentronic, manual mode

Paddles on the steering wheel for changing gear manually

Selector positions

Engine can be started. The key can be removed

Adaptive gear-change patterns

Sport modes

Cruise control

When the ESP system is operative for more than 1 second

To reduce the preset speed

Brake pad wear indicators

Braking

ABS brakes

Braking with ABS evasive steering

Electronic Stability Program ESP

How the ESP system works

Turning the ESP system off

ESP indicator light

ESP OFF-indicator light

ESP button

Parking brake

When the parking brake is on, the indicator

Parking

Pointing uphill and against the curb

Parking on a hill

Pointing downhill and against the curb

Pointing uphill or downhill no curb

Long-term parking

Area monitored by the sensors seen from the side

Saab Parking Assistance

Area monitored by the sensors seen from above

Seconds

Consumption

Economical motoring

Factors affecting fuel

Breaking-in

Driving technique

Road conditions

Engine block heater

Driving in cold weather

Heat it first or spray it with de-icer

Driving in hot weather

Tire chains

Towing a trailer

Trailer hitch attachment

Recommendations for driving in hilly terrain

Trailer weight

Maximum recommended trailer weights for different gradients

1500 Unlimited

Recommendations for cars with automatic transmission

Gearbox too hot Make a safe stop

Checks before driving

Driving considerations

Recommendations for cars with manual gearbox

Distribution of load in trailer

Attach the safety chains to the holes as illustrated

Trailer hitch load

Light Moderate Heavy

Driving with a roof rack load

Fitting the roof carriers SportCombi with roof rails

Driving with a load

Driving at night

Tire pressure, see page 268 and back cover

Tires

Driving in deep water

Driving with a spare wheel fitted

Driving with the trunk lid/tailgate open

Towing the car

Front towing eye

Front towing eye

Rear towing eye

Rear towing eye

Transporting the car

Towing the car

Never use the towing eyes to pull the car unstuck

Jump starting

Starting and driving

Charging the battery/Jump starting

Car care and technical information

Hood

Hood secondary safety catch

Hood release handle

Engine compartment

Emission control systems

Engine families

Orvr Onboard Refueling Vapor Recovery

Saab Trionic engine management system

Checking the oil level

Engine

Engine oil

Balance shafts

Transmission fluid Coolant

Coolant expansion tank

Brake and clutch fluid

Checking the fluid level

Brake and clutch-fluid reservoir

Power steering fluid

Air filter

Battery

Battery

Charging/replacing the battery

Battery size must comply with DIN 53735 MFI 230/2.16

Correct position for battery clamp

Routing of the drive belt

Drive belts

See also page 59, Warning, charging

Changing the windshield wiper blades

Check and clean all wiper blades regularly

Cleaning/adjusting the washer jets

Washer jets

Washer-fluid reservoir holds 6.4 quarts 6 liters. When

Washers

Washer-fluid filler cap

Washer fluid level low. Refill

Use only Long Life bulbs

Changing bulbs

Xenon headlight

Headlight aiming, see

Headlight bulb for high beam Halogen

Low beam bulb

Headlight bulb for low beam Halogen

Parking-light bulb

Front direction indicator

Parking-light bulb

Front fog lights

Rear light clusters, 9-5 Sedan

Rear light cluster, 9-5 Sedan

Rear light clusters, 9-5 SportCombi

Changing bulbs

Trunk lid light and taillights, 9-5 Sedan

Refitting the trim

Rear lights clusters, 9-5 SportCombi

High-mounted stop lights, 9-5 Sedan

High-mounted stop lights

Reassembly

Reassembly

Tailgate bulbs, 9-5 SportCombi

Side direction indicators

License-plate light

Glove-compartment illumination

Dome light, front

Dome light, rear

Other bulbs

Bulb table

Cap Wattage

Sound fuse / Blown fuse

Fuses

Fuse panel in instrument panel

Maxi fuses

Maxi fuses under the hood

Fuse panel in instrument panel

Amp Function

Relay panel under instrument panel

# Function

Starter relay Limp-home function

Fuse box under hood

Fuses Amp Function

Relays Function

Tires

Inflation Tire Pressure

High speed operation

When to check

How to Check

Tire Inspection and Rotation

Wear indicators

When It Is Time for New Tires

Treadwear indicators

Flat spotting

Buying New Tires

Uniform Tire Quality Grading

Treadwear 200 Traction AA Temperature a

Temperature A, B, C

Treadwear

Wheel Alignment and Tire Balance

Wheel Replacement

Used Replacement Wheels

See Changing a wheel on

If a Tire Goes Flat

Uniform Tire Quality Grading Utqg

Tire Sidewall Labeling

Tire Size

215

Speed ratings

Tire markings

Tire load index

TIN-code

Loading Your Vehicle

Tire Terminology and Definitions

Car care and technical information

Steps for Determining Correct Load Limit

Winter tires

Spare wheel under panel in luggage compartment

Tire date code

Do not exceed 50 mph 80 km/h with the compact spare fitted

Following should be observed when

Driving considerations with

Compact spare wheel/tire fitted

Hanging up the cover, 9-5 SportCombi

Changing a wheel

Switch on the hazard warning lights if the car is on a road

Set the parking brake firmly

Car care and technical information 237

Jacking points for a floor jack

Light-alloy wheels 80 ft.lbs Nm Steel wheels 80 ft.lbs Nm

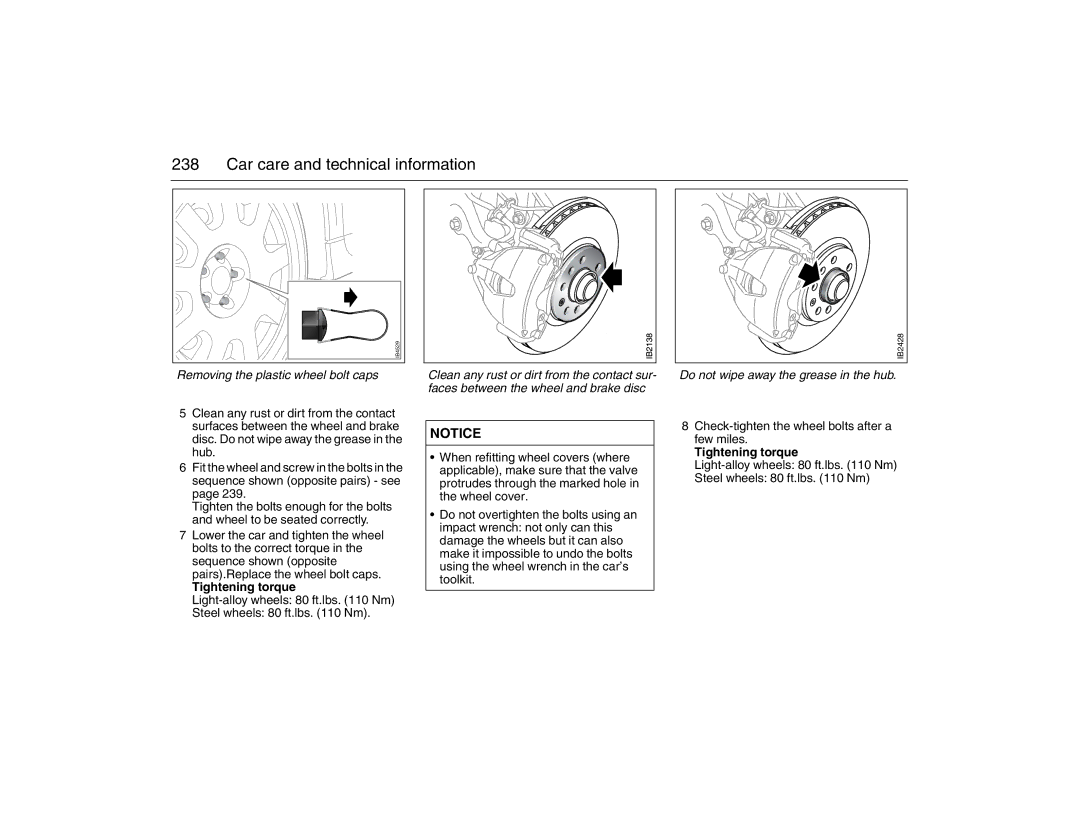

Removing the plastic wheel bolt caps

Tightening torque

Do not wipe away the grease in the hub

Tightening sequence, wheel bolts

Removing the wheel cover

Upholstery and trim

Cleaning and caring for leather upholstery

Textile carpeting

Washing the car

Waxing and polishing

Touching up the paint

Surface-treatment composition

Air conditioning ACC

Two-coat enamel

A/C system is designed for use with R134a refrigerant

Maintenance

Fault diagnosis

Inadequate cooling

Anti-corrosion treatment

Preventive maintenance

What causes rust?

For long trips

Kg on the drivers seat

IB1950

Vertical aiming device

Aiming marker on headlight lens

This page has been left blank

Customer Assistance and Information

Service intervals

Maintenance schedule

Engine oil and filter changes

Warranties and service problem assistance

Service record retention

Service costs

Owner assistance

Service information

Reporting Safety Defects U.S.A

Reporting Safety Defects to the Canadian government

Change of Address Notification U.S. and Canada

Vehicle Data Collection and Event Data Recorders

This page has been left blank

Specifications

VIN on cars sold

General

Specified track applies to wheel sizes

Chassis number in engine bay

Trailer

Luggage compartment

Shafts, 16 valves

Cylinder

Overhead cam

Two balancer

Recommended oil viscosity

Approved engine oils

Servicing/Oil changes

For gasoline engines

220 hp 162 kW

When to change engine oil

3T Ecopower

228.6 ft.lb 310 Nm

Engine variants Outside length

PFR 6H-10

PFR 6H-10 0374 in 0.95 mm

Drive belt 95.08 2415 mm

Type

Type All-synchromesh

Tial

Speed mph / km/h at 1000 rpm in 5th gear 27-29

Joints

Number of turns, lock to lock Power-steering fluid

Dampers Front Gas-filled Rear

CHF 11S or

Winter tires

Wheels and tires recommended dimensions

All season tires

Wheel sizes

Lowest recommended tire pressure, cold tires

Chassis number, stamped on body

Manufacturer

Region

Country

Product line Model series

Following adjustments can be done by the driver

ACC functions Battery Charge mobile phone

System, fault diagnosis Data

System, maintenance

Battery charging/replacing

DICE/TWICE

Frequently asked questions on airbag

Electrical system, technical data Fuel container

Dampers

Index

Remote-control battery, changing Service costs Suspension

Rear seat, 9-5 SportCombi, folding 132 Safety belts

Remote control Sentronic, manual mode

Remove the key 140 Service information

Textile carpeting

Technical data 257

Temperature zones, ACC

Through-load hatch

Index

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page