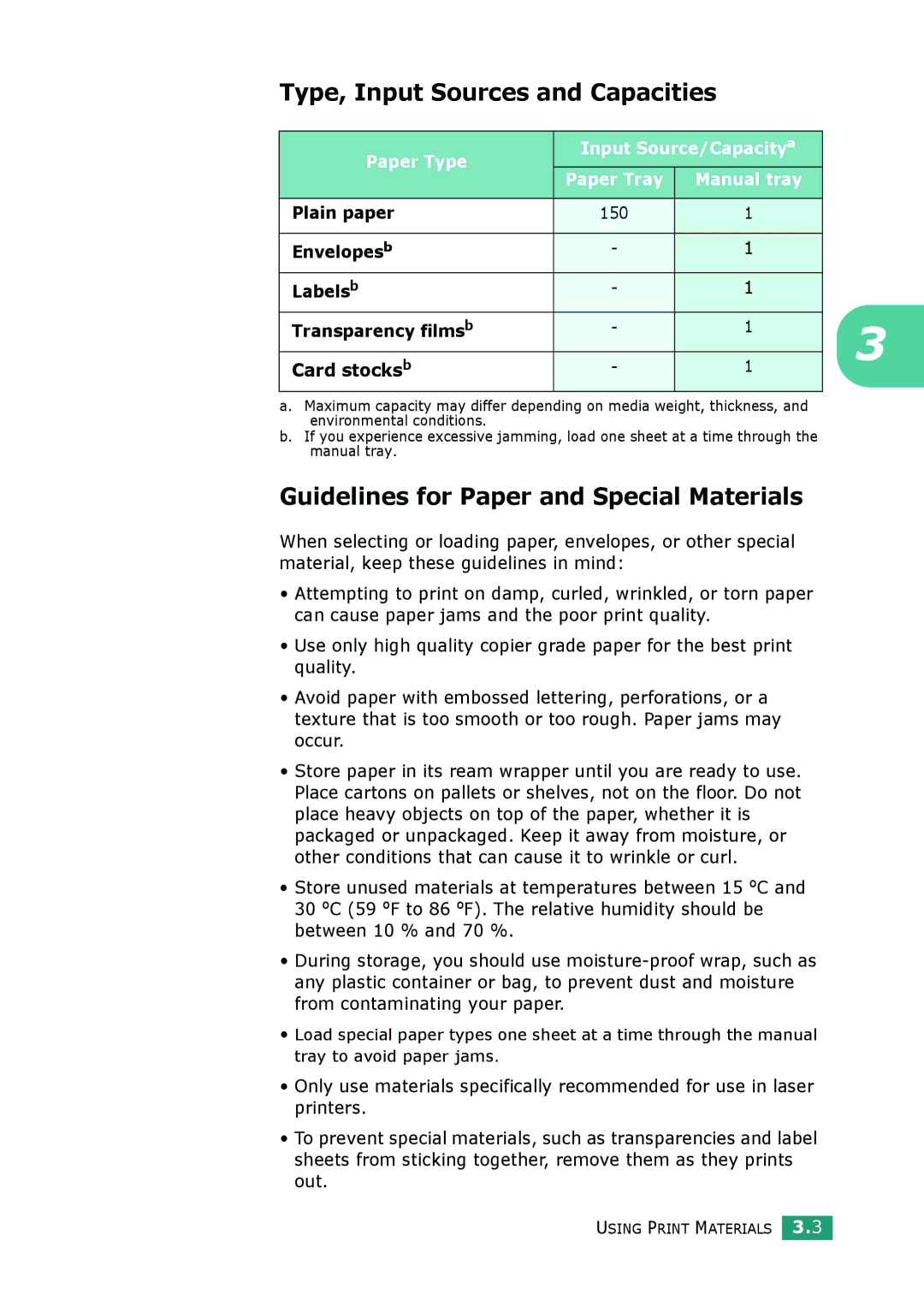

Type, Input Sources and Capacities

Paper Type | Input Source/Capacitya |

|

| |

| Paper Tray | Manual tray |

|

|

|

|

|

|

|

Plain paper | 150 | 1 |

|

|

|

|

|

|

|

Envelopesb | - | 1 |

|

|

Labelsb | - | 1 |

|

|

Transparency filmsb | - | 1 | 3 | |

|

| |||

Card stocksb | - | 1 |

|

|

a.Maximum capacity may differ depending on media weight, thickness, and environmental conditions.

b.If you experience excessive jamming, load one sheet at a time through the manual tray.

Guidelines for Paper and Special Materials

When selecting or loading paper, envelopes, or other special material, keep these guidelines in mind:

•Attempting to print on damp, curled, wrinkled, or torn paper can cause paper jams and the poor print quality.

•Use only high quality copier grade paper for the best print quality.

•Avoid paper with embossed lettering, perforations, or a texture that is too smooth or too rough. Paper jams may occur.

•Store paper in its ream wrapper until you are ready to use. Place cartons on pallets or shelves, not on the floor. Do not place heavy objects on top of the paper, whether it is packaged or unpackaged. Keep it away from moisture, or other conditions that can cause it to wrinkle or curl.

•Store unused materials at temperatures between 15 oC and 30 oC (59 oF to 86 oF). The relative humidity should be between 10 % and 70 %.

•During storage, you should use

•Load special paper types one sheet at a time through the manual tray to avoid paper jams.

•Only use materials specifically recommended for use in laser printers.

•To prevent special materials, such as transparencies and label sheets from sticking together, remove them as they prints out.

USING PRINT MATERIALS 3.3