Page

About the User’s Guide

Contents

Scanning Basics

Printing a Document Canceling a Print Job

Available Fax Setup Options

Canceling a Scheduled Fax

Clearing the Memory

Cleaning the Drum

General Specifications 10.1

Printer Specifications 10.2

Use only No.26 AWG or larger telephone line cord

Important Precautions and Safety Information

Laser Safety Statement

Ozone Safety

Radio Frequency Emissions

Mercury Safety

Power Saver

Recycling

You should also know that

Ringer Equivalence Number

Declaration of Conformity European Countries

Replacing the Fitted Plug for UK Only

Neutral

Wires in the mains lead have the following color code

British English American English

Differences Between British and American English

Introduction

Special Features

Understanding Component Locations

Front View Rear View

These are the main components of your machine

Control Panel Functions

Unpacking

Getting Started

Left 3.9 in./100 mm enough space for ventilation

Installing the Toner Cartridge

Selecting a Location

Clearance Space

Loading Paper

Skip this step and proceed to step

Making Connections

Load paper with the print side facing up

If you have SCX-4321

For France users only Getting Started

Turning the Machine On

Macintosh Driver

Installing Printer Software

System Requirements

Programs for Windows

Feature

Printer Driver Features

Setting Language

Setting Country

Changing Numbers or Names

Setting the Machine ID

Entering Characters Using Number Keypad

Keypad Letters and Numbers

Setting the Date and Time

Setting the Paper Size and Type

Changing the Clock Mode

Toner Save Mode

Using the Save Modes

Speaker, Ringer, Key Sound, and Alarm Sound

Speaker Volume

Machine is connected

Setting the Dial Mode

Paper Type Input Tray/Capacity

Paper Handling

Selecting Print Materials

Paper Type, Input Sources, and Capacities

Guidelines for Paper and Special Materials

Tray holds 150 sheets of paper

Using the Tray

Using the Manual Tray

Verifying an Output Location

Copying

Loading Paper for Copying

Preparing a Document

Lift and open the document cover

Adjust the document guides to the document size

Making Copies on the Document Glass

Making Copies from the Automatic Document Feeder

Reduced/Enlarged Copy

Setting Copy Options

Darkness

Original Type

Auto Fit Copying

Using Special Copy Features

Clone Copying

Collation Copying

ID Card Copying

Up or 4 Up Copying

Poster Copying

Changing the Default Settings

Setting the Time Out Option

Setting the Favorite Copy Option

Basic Printing

Canceling a Print Job

Printing a Document Canceling a Print Job

From the Document menu, select Cancel Printing

Scanning

Scanning Basics

Your SCX-4x21 Series offers four ways to scan. These are

Changing the Fax Setup options

Available Fax Setup Options

Option Description

You can select the default fax receiving mode

On, Off, and On-Err, which prints only when a

For more information about using the code

Drpd Mode on

To fax a document using the Automatic Document Feeder ADF

Loading a Document

To fax a document from the document glass

Adjusting the Document Resolution

Mode Recommended for

Sending a Fax Automatically

Automatic Redialing

Sending a Fax Manually

Redialing the Last Number

Confirming Transmission

About Receiving Modes

Receiving Automatically in Fax Mode

Receiving Manually in Tel Mode

Receiving Automatically in Ans/ Fax Mode

Receiving Manually Using an Extension Telephone

Receiving Faxes Using the Drpd Mode

Receiving Faxes in the Memory

Group Dialing

Sending a Fax using a Speed Dial Number

Setting a Group Dial Number

Speed Dialing

Press Phone Book

Searching for a Number in Memory

Editing Group Dial Numbers

Searching Sequentially through the Memory

Printing a Phonebook List

Sending Broadcast Faxes

Searching with a Particular First Letter

Sending a Delayed Fax

Sending a Priority Fax

If you do not want to assign a name, skip this step

Adding Documents To a Scheduled Fax

Canceling a Scheduled Fax

Printing Reports

Using Secure Receiving Mode

Power Failure Report

Using Advanced Fax Settings

Changing Setting Options

Advanced Fax Setting Options

Clearing the Memory

Maintenance

Cleaning the Inside

Setting the Machine to be Checked by Phone

Cleaning Your Machine

Cleaning the Outside

Saving toner

Cleaning the Scan Unit

Maintaining the Toner Cartridge

Toner cartridge storage

Setting the Notify Toner Option

Redistributing Toner

Replacing the Toner Cartridge

Cleaning the Drum

Ignoring the Toner Empty Message

Items Yield Average

Replacing the ADF Rubber Pad

Troubleshooting

Clearing Document Jams

Input Misfeed

Message Location of Jam Go to

Exit Misfeed

Tray

Manual Tray

Paper Exit Area

Fuser Area or Around the Toner Cartridge

Clearing LCD Error Messages

Display Meaning Suggested solutions

Tips for Avoiding Paper Jams

Service

Low Heat Error

Unplug the power cord

Open Heat Error

Stop/Clear

Solving Other Problems

Paper Feeding Problems

Condition Suggested solutions

Condition Possible cause Suggested solutions

Printing Problems

Toner specs

Printing Quality Problems

Light or faded

Print

Scatter Distributed on the printed

Condition Suggested solutions Background

Copying Problems

Scanning Problems

Problem Possible Cause and Solution

Common Linux Problems

Common Macintosh Problems

Problems in Printer Setup Utility

Software. See Software User’s Guide

General Specifications

Specifications

Module

Scanner and Copier Specifications

Printer Specifications

Compatibility Twain standard / WIA standard Scanning method

Facsimile Specifications

Paper Specifications

Overview

Supported Sizes of Paper

Guidelines for Using Paper

Paper Dimensions Weight Capacity

Symptom Problem with Paper Solution

Envelopes

Paper Specifications

Paper Output Capacity

Paper Storage Environment

Envelope Storage

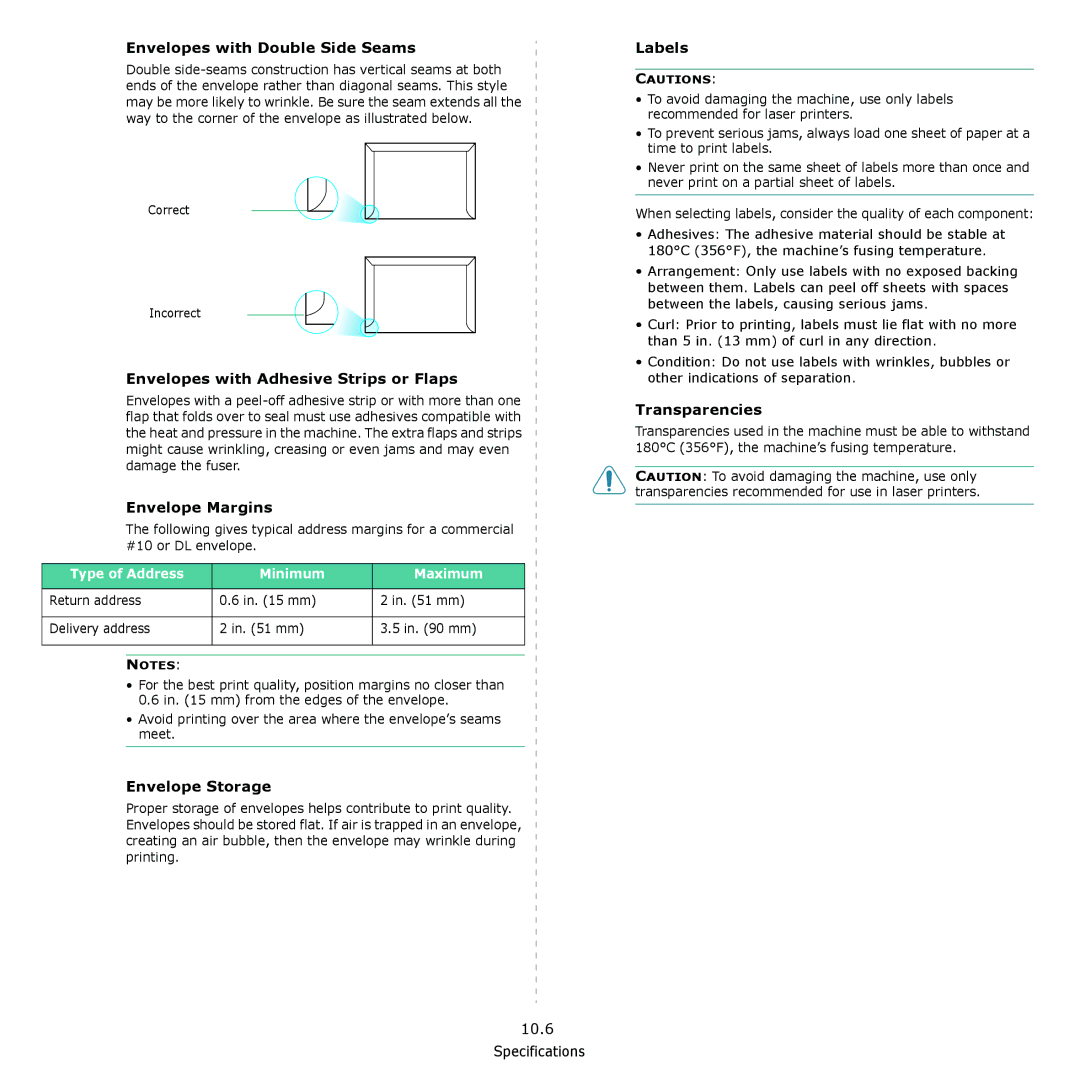

Envelopes with Double Side Seams

Envelopes with Adhesive Strips or Flaps

Envelope Margins

Index

Page

Software User’s Guide

Contents

Sharing the Printer Locally

Using Your Printer with a Macintosh

Installing Printer Software in Windows

Installing Printer Software in Windows

Choose the type of installation

Removing Printer Software

Reinstalling Printer Software

Select your printer driver from the Name drop-down list

Layout Options

Printer Settings

Layout Tab

Orientation

Scaling

Paper Tab

Copies

Size

Advanced Options

Resolution

Toner Save Mode

Graphics Tab

Extras Tab

About Tab

Printer Tab

Using Help

Using a Favorite Setting

Printing Multiple Pages on One Sheet of Paper N-Up Printing

Advanced Printing

Printing a Reduced or Enlarged Document

Printing Posters

Click OK and start printing Advanced Printing

Using Watermarks

Using an Existing Watermark

Fitting Your Document to a Selected Paper Size

Watermark section. The Edit Watermark window appears

Creating a Watermark

Editing a Watermark

Deleting a Watermark

Edit Overlay window, click Create Overlay

Using Overlays

What is an Overlay?

Creating a New Page Overlay

Using a Page Overlay

Deleting a Page Overlay

Click Delete Overlay

Check the Share this printer box

Setting Up a Host Computer

Setting Up a Client Computer

Sharing the Printer Locally

To exit, click the Exit button at the bottom of each tab

Using Printer Settings Utility

Scan Settings Tab

Restore Defaults

Phonebook Tab fax available

Firmware Update Tab

Custom You may choose the options you want to install

Scanning Using Samsung SmarThru

Installing Samsung SmarThru

Click Install SmarThru

Using Samsung SmarThru

Uninstalling Samsung SmarThru

Using Onscreen Help File

Scanning Using the WIA Driver

Scanning Process with TWAIN- enabled Software

Using Your Printer in Linux

Installing the MFP Driver

Getting Started

Installing the MFP Driver

Click Uninstall

Using the MFP Configurator

Uninstalling the MFP Driver

Opening the MFP Configurator

Classes Tab

Printers Configuration

Scanners Configuration

Printers Tab

Configuring Printer Properties

MFP Ports Configuration

Sharing Ports Between Printers and Scanners

Printing from Applications

Printing Files

To print any document file

Click Properties

Scanning a Document

Using the Image Editor

Adding Job Type Settings

You can use the following tools to edit the image

Uninstalling the Printer driver

Using Your Printer with a Macintosh

Installing Software for Macintosh

Install the Printer driver

For a Network-connected Macintosh

Setting Up the Printer

Install the Scan driver

Uninstalling the Scan driver

Printing a Document

Changing Printer Settings

Layout Setting

Printing

Select the page order from the Layout Direction option

Printer Features Setting

Printing Multiple Pages on One Sheet of Paper

Paper Type

Scanning

Index

Toner save, set 10 TWAIN, scan

Toner save 10 true-type option

Rev.1.0