EVS Toolroom Lathe w/DRO

Customer Service

Updates

Scope of Manual

Manual Feedback

Table of Contents

Warranty

About This Machine

Features

Foreword

Capabilities

General identification Model SB1060PF shown

General Identification

Controls Components

Master Power Switch

Headstock Controls

Carriage Controls

Control Panel

Tailstock Controls

Adjustable carriage clutch knob

Foot brake and spindle ON/OFF lever

Foot Brake

Model SB1059F, SB1060PF, SB1061PF EVS Toolroom Lathe w/DRO

Product Specifications

Main Motor

Tailstock Information

Construction

Model Number SB1042PF SB1043PF SB1045PF

Model SB1042PF, SB1043PF, SB1045PF EVS Toolroom Lathe w/DRO

Main Motor

Headstock Information

Construction

Understanding Risks of Machinery

Basic Machine Safety

F E T Y

Additional Metal Lathe Safety

Additional Chuck Safety

Things Youll Need

Preparation Overview

Typical preparation process is as follows

Availability

Power Supply Requirements

Full-Load Current Rating

Circuit Requirements

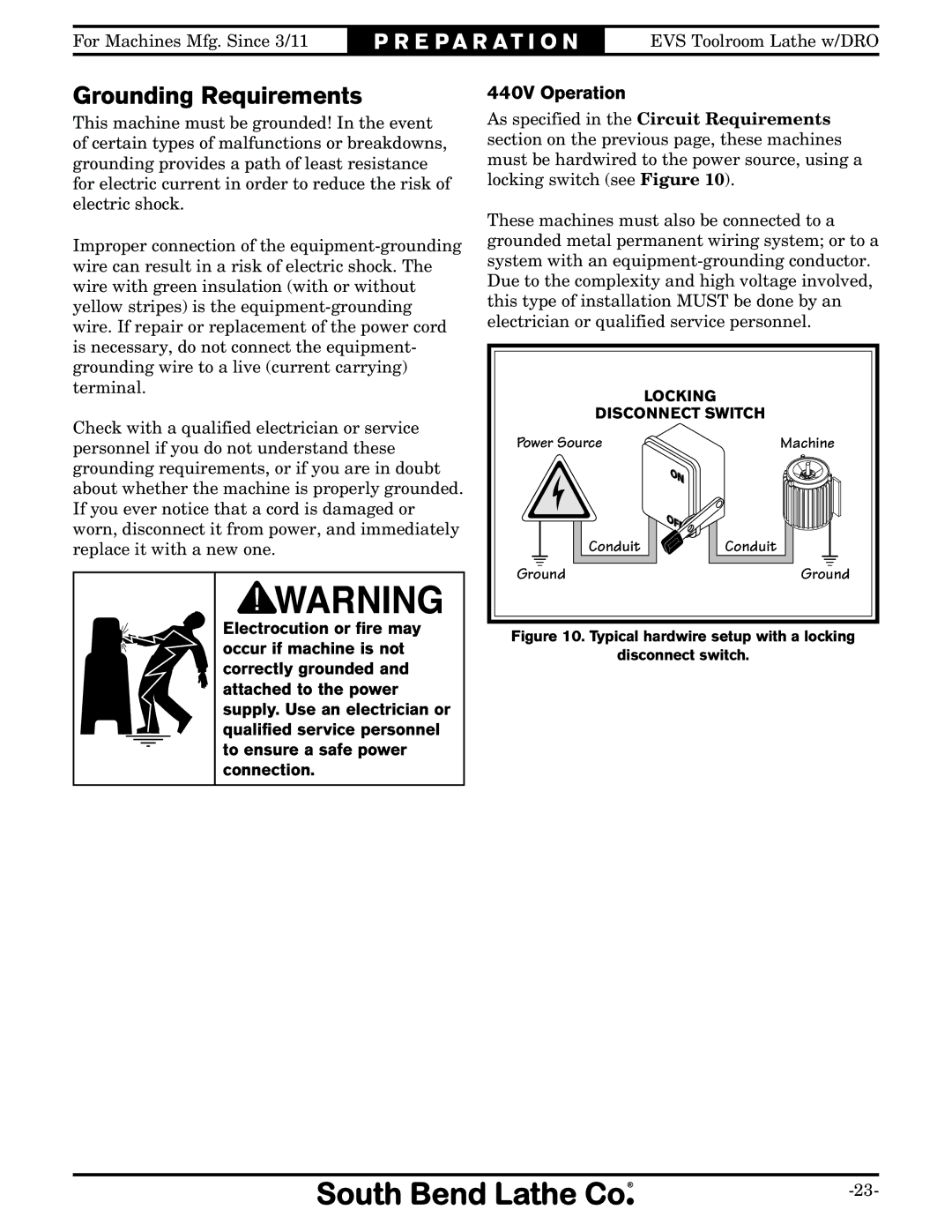

440V Operation

Grounding Requirements

Unpacking

Installed & Not Shown Qty

Inventory

Main Inventory 1 Figure Qty

Before cleaning, gather the following

Cleaning & Protecting

Basic steps for removing rust preventative

Location

To lift and move the lathe

Lifting & Moving

Leveling

Leveling & Mounting

Lubricating Lathe

Assembly

Bolting to Concrete Floors

Adding Coolant

Power Connection

Supply

Connecting Power

To test run your machine

Test Run

Engaged

E P a R a T I O N

Factory adjustments that should be verified

Recommended Adjustments

Spindle Break-In

To perform the spindle break-in

Operation Overview

Chuck & Faceplate Mounting

Installation & Removal Devices

To install the chuck

Chuck Installation

Registration Marks

Chuck Removal

To remove the chuck

Jaw Chuck

Scroll Chuck Clamping

Mounting Workpiece

Jaw tightening sequence

Faceplate

Tailstock

Using Quill

Positioning Tailstock

To mount a non-concentric workpiece to the faceplate

To install tooling in the tailstock

Installing Tooling

Removing Tooling

Offsetting Tailstock

To offset the tailstock

Tools Needed Qty

Items Needed Qty

Aligning Tailstock to Spindle Centerline

To align the tailstock to the spindle centerline

Dead Centers

Centers

Mounting Dead Center in Spindle

Live Centers

Removing Center from Spindle

Mounting Center in Tailstock

Mounting Workpiece Between Centers

Removing Center from Tailstock

Steady Rest

To install and use the steady rest

Compound Rest

Follow Rest

Tool Needed Qty

To set the compound rest at a certain angle

To install a tool in the tool post

Installing Tool

Four-Way Tool Post

Aligning Cutting Tool with Spindle Centerline

To align the cutting tool with the tailstock center

Micrometer Stop

Top View To set the micrometer stop

Side View

Spindle Speed

Manual Feed

Setting Spindle Speed

Power Feed

Gearbox range lever

Power Feed Controls

Apron feed selection and direction knobs

Example Power Feed Rate of 0.0025/rev

Setting Power Feed Rate

Standard End Gear Configuration

End Gears

Alternate End Gear Configuration

Configuring End Gears

Headstock & Gearbox Threading Controls

Threading Controls

Example Metric Thread Pitch of 2.5mm

Engaged

Apron Controls

Thread Dial

Thread Dial Chart

TPI Divisible By

Odd Numbered TPI

Even TPI Not Divisible By

⁄2 Fractional TPI

⁄4 or 3⁄4 Fractional TPI

Coolant System

Chip Drawer

To use the coolant system on your lathe

Rod Support

SB1279-10 Pc. Precision 5-C Collet Set

Accessories

SB1272-Collect Attachment

SB1271-Taper Attachment

Maintenance Schedule

South Bend Lathe Co. Lathe Monthly Maintenance Chart

Lubrication

Oil Pressure Safety Switch

Headstock

Changing Headstock Oil

Checking & Adding Oil

Items Needed Qty

Draining headstock oil

To to change the headstock oil

Apron

Quick-Change Gearbox

Draining Oil

Checking Oil Level

Draining Oil & Flushing Reservoir

One-Shot Oiler

Ball Oilers

Longitudinal Leadscrew

Handling & Care

End Gears

Lubricating

Hazards

Coolant System Service

Changing Coolant

Adding Fluid

To change the coolant

To prepare the lathe for storage

Machine Storage

Compound Rest

Backlash Adjustment

Cross Slide

Gib Adjustment

Leadscrew End Play Adjustment

To remove leadscrew end play

Front saddle gib adjustment screw Carriage Lock Clamp

To adjust the V-belts

Half Nut Adjustment

To adjust the half nut

Belts

Needed Qty

Brake Service

To replace the brake shoes

Brake switch

To replace the shear pin

Leadscrew Shear Pin Replacement

Shear pin access

Gap Removal

Gap Insert Removal & Installation

Gap Installation

TR O U B L E S H O OTI N G

TR O U B L E S H O OTI N G

TR O U B L E S H O OTI N G

Wiring Diagram Color KEY

Electrical Safety Instructions

To correct wiring that is out of phase

Correcting Phase Polarity

ON/OFF

Wiring Overview

Component location index

Component Location Index

Page100

Electrical Box Wiring

To Incoming Power

Electrical box

Electrical Box

Oil Pump Motor & Pressure Sensor

Spindle Motor

Motor

Spindle ON/OFF Switch

Coolant Pump Wiring

Disconnect

Control Panel Wiring

Pontnet

Additional Component Wiring

Headstock Housing

Description

Headstock Housing Parts List

122

Headstock Gears

105

Pipe Plug 1/2 NPT

Headstock Gears Parts List

Gearbox

Gearbox

Description

Gearbox Parts List

110

Apron

112

Apron Parts List

114

720 723 724 719 726 716

Tool Post & Compound Rest

825

Saddle & Cross Slide

117

118

Saddle & Cross Slide Parts List

Bed & Shafts

BED GAP Piece SB1059F

Bed & Shafts Parts List

1016 1002 1001 1007 1006

End Gears SB1042PF, SB1043PF, SB1045PF

End Gears SB1059F, SB1060PF, SB1061PF

Motor & Headstock Oil System

PVA75

Motor & Headstock Oil System Parts List

Stand & Panels SB1042PF-43PF, SB1059F-61PF

PW03M Flat Washer 6MM

Stand & Panels Parts List SB1042PF-43PF, SB1059F-61PF

Stand & Panels SB1045PF

Upper Catch Tray

Stand & Panels Parts List SB1045PF

1312

Steady Rest Follow Rest

1558 1550 1551 1552 1554 1553 1555 1556 1559 1560

Micrometer Stop Thread Dial

Brake

Control Panel Viewed from Behind

Electrical Cabinet & Control Panel

1802

1910

Front Machine Labels

Rear Machine Labels

Warranty

Southbendlathe.com