XR-1520, XR-1020 specifications

The Star Micronics XR-1520 and XR-1020 series printers are durable, high-performance devices designed for a variety of printing applications, particularly in retail and hospitality environments. These compact printers are engineered to deliver efficient receipt and label printing, catering to the needs of businesses that demand reliability and speed.One of the standout features of the XR-1520 and XR-1020 is their advanced thermal printing technology. This method eliminates the need for ink or toner, reducing the operational costs significantly while also minimizing maintenance. The printers utilize direct thermal printing, which produces high-quality prints with sharp text and graphics. This is particularly advantageous for businesses that require clear and legible receipts.

Both models are equipped with fast print speeds, capable of delivering up to 200 mm per second. This ensures quick transaction times, enhancing customer satisfaction and streamlining service. The XR-1520, designed for high-volume environments, can handle larger print jobs efficiently, while the XR-1020 is ideal for smaller businesses or those with moderate printing needs.

Durability is another critical feature of these printers. Star Micronics has engineered the XR series to withstand the rigors of a busy retail environment. They boast robust construction that protects against everyday wear and tear, while their compact design allows for easy placement on countertops or in tight spaces.

Connectivity options are versatile, accommodating a range of modern point-of-sale systems. The XR-1520 and XR-1020 support USB, Ethernet, and serial connections, ensuring compatibility with various devices. Additionally, they are equipped with Bluetooth capabilities, allowing for wireless printing from mobile devices, further enhancing their functionality.

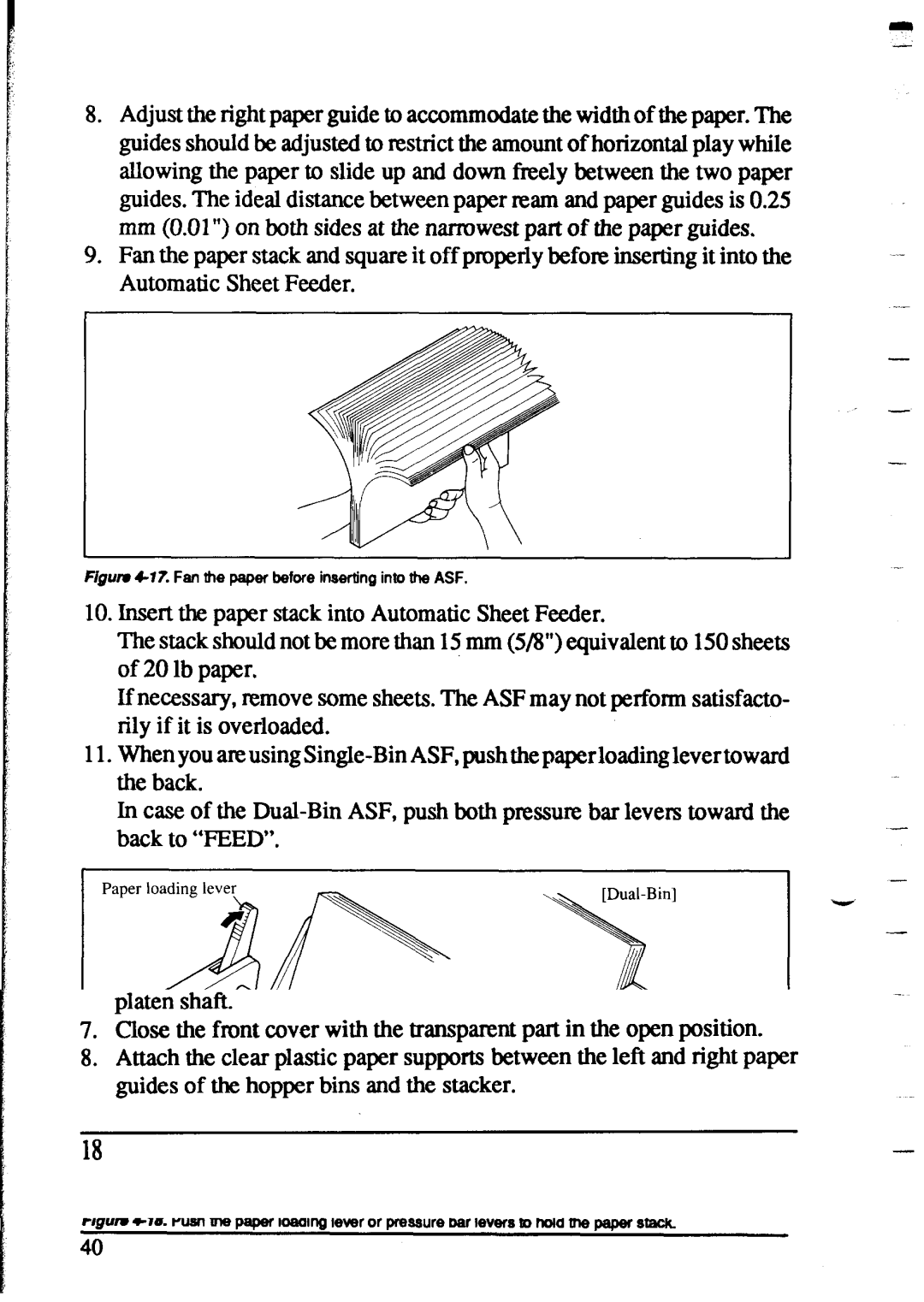

User-friendliness is paramount in the design of both models. They come with intuitive controls for easy operation and integration. They also feature an easy paper loading mechanism that reduces the downtime associated with replacing paper rolls.

In summary, the Star Micronics XR-1520 and XR-1020 printers stand out with their advanced thermal printing technology, high-speed performance, robust durability, versatile connectivity options, and user-friendly design. These characteristics make them an excellent choice for businesses seeking dependable, efficient, and high-quality printing solutions.