Throughput.

Press throughput specifies the total weight of material through the extruder per minute. The value can be entered in grams, kilograms, ounces, or pounds per minute. The unit of measure is changed by pressing the units button at the middle right of the screen. Changing the unit of measure will NOT change the value displayed on the screen. It is important that this value be adjusted whenever the extruder speed changes.

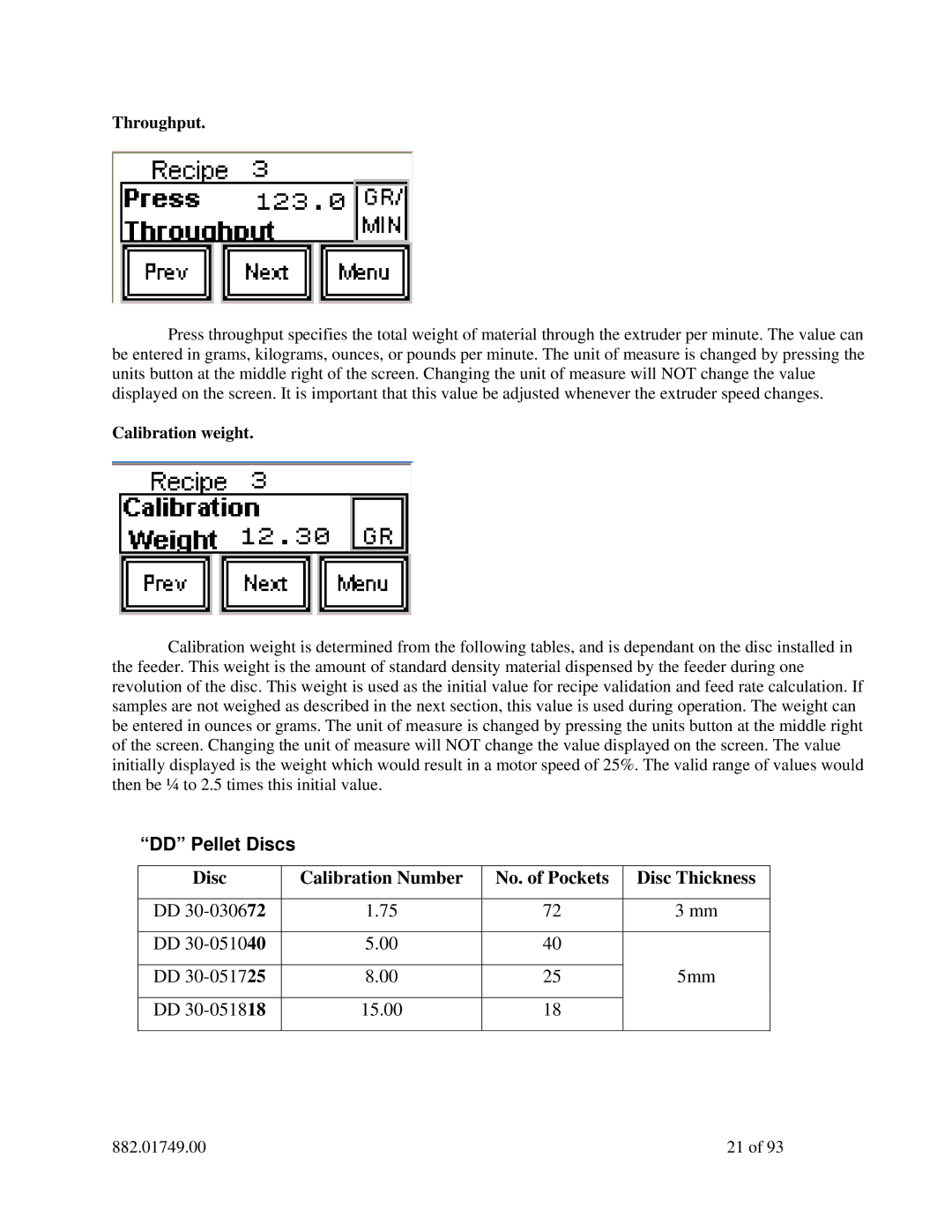

Calibration weight.

Calibration weight is determined from the following tables, and is dependant on the disc installed in the feeder. This weight is the amount of standard density material dispensed by the feeder during one revolution of the disc. This weight is used as the initial value for recipe validation and feed rate calculation. If samples are not weighed as described in the next section, this value is used during operation. The weight can be entered in ounces or grams. The unit of measure is changed by pressing the units button at the middle right of the screen. Changing the unit of measure will NOT change the value displayed on the screen. The value initially displayed is the weight which would result in a motor speed of 25%. The valid range of values would then be ¼ to 2.5 times this initial value.

“DD” Pellet Discs

Disc | Calibration Number | No. of Pockets | Disc Thickness |

|

|

|

|

DD | 1.75 | 72 | 3 mm |

|

|

|

|

DD | 5.00 | 40 |

|

|

|

| 5mm |

DD | 8.00 | 25 | |

|

|

|

|

DD | 15.00 | 18 |

|

|

|

|

|

882.01749.00 | 21 of 93 |