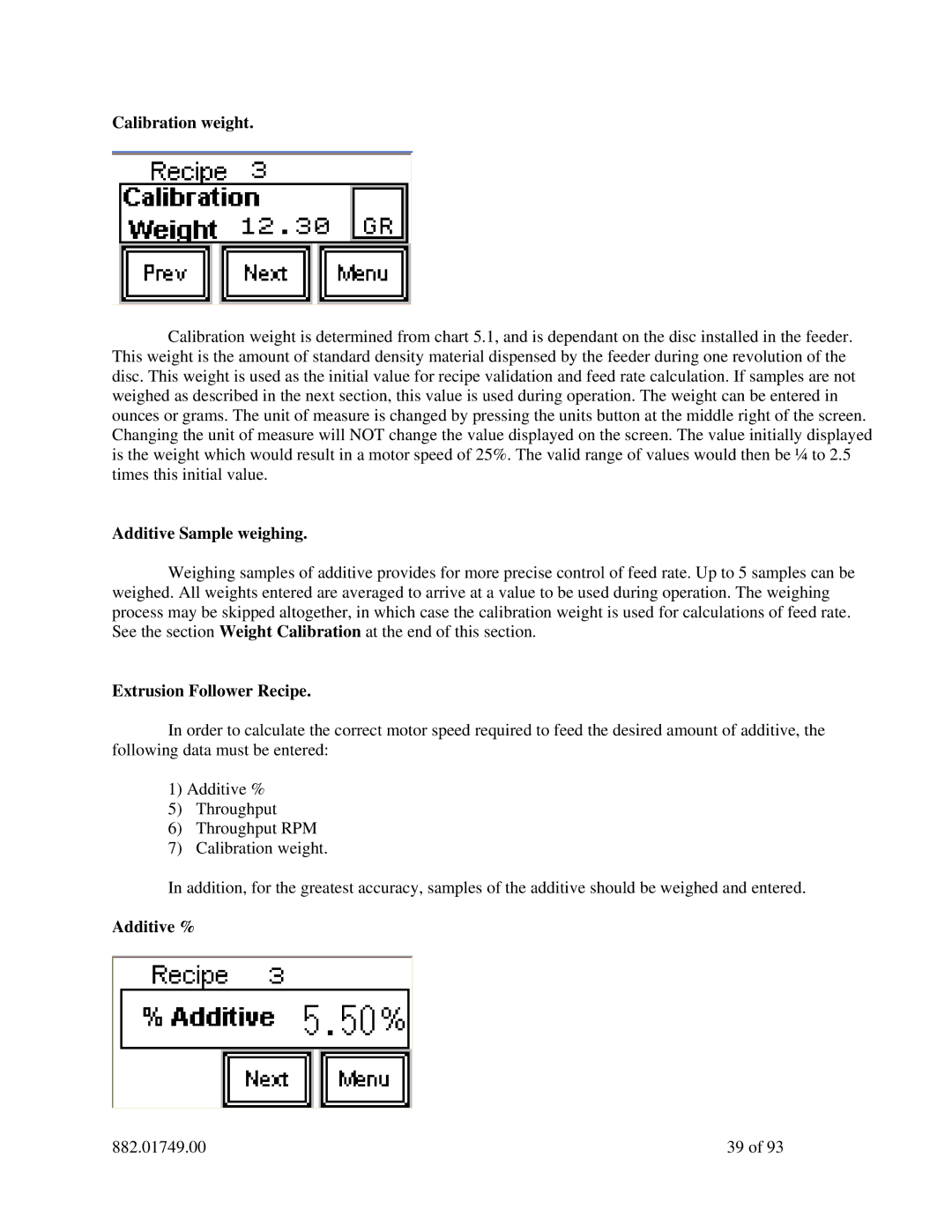

Calibration weight.

Calibration weight is determined from chart 5.1, and is dependant on the disc installed in the feeder. This weight is the amount of standard density material dispensed by the feeder during one revolution of the disc. This weight is used as the initial value for recipe validation and feed rate calculation. If samples are not weighed as described in the next section, this value is used during operation. The weight can be entered in ounces or grams. The unit of measure is changed by pressing the units button at the middle right of the screen. Changing the unit of measure will NOT change the value displayed on the screen. The value initially displayed is the weight which would result in a motor speed of 25%. The valid range of values would then be ¼ to 2.5 times this initial value.

Additive Sample weighing.

Weighing samples of additive provides for more precise control of feed rate. Up to 5 samples can be weighed. All weights entered are averaged to arrive at a value to be used during operation. The weighing process may be skipped altogether, in which case the calibration weight is used for calculations of feed rate. See the section Weight Calibration at the end of this section.

Extrusion Follower Recipe.

In order to calculate the correct motor speed required to feed the desired amount of additive, the following data must be entered:

1) Additive %

5)Throughput

6)Throughput RPM

7)Calibration weight.

In addition, for the greatest accuracy, samples of the additive should be weighed and entered.

Additive %

882.01749.00 | 39 of 93 |