Extrusion - Constant: Wire the “cycle/run” cable (two- conductor gray cable) to a set of dry (NO VOLTAGE) contacts that CLOSE when the screw rotates. (See Figure 5.) The connection inside the controller should be on terminal block #10 and PLC input X5.

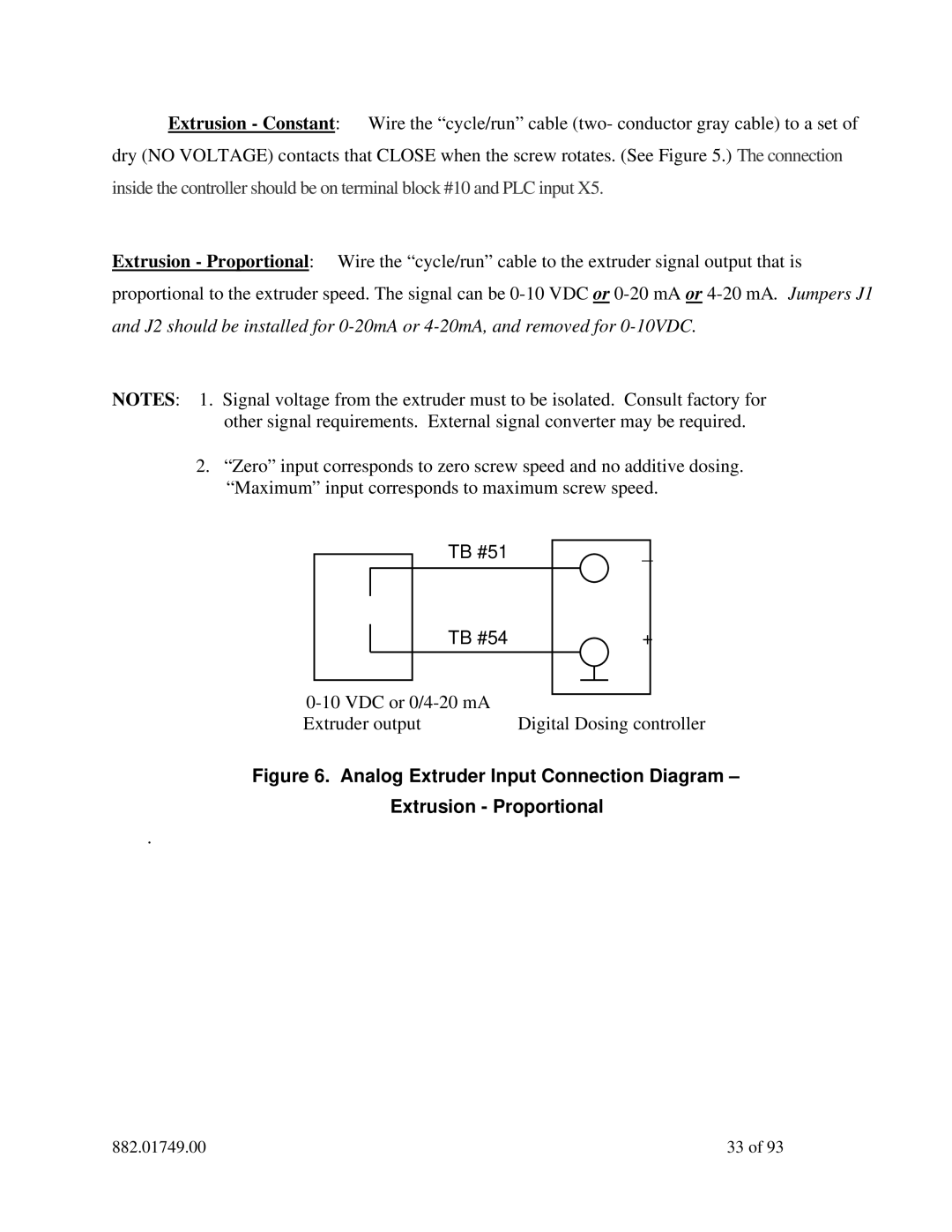

Extrusion - Proportional: Wire the “cycle/run” cable to the extruder signal output that is proportional to the extruder speed. The signal can be

NOTES: 1. Signal voltage from the extruder must to be isolated. Consult factory for other signal requirements. External signal converter may be required.

2.“Zero” input corresponds to zero screw speed and no additive dosing. “Maximum” input corresponds to maximum screw speed.

TB #51 | _ |

|

|

| TB #54 | + | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

| ||||

Extruder output | Digital Dosing controller | ||||||||

Figure 6. Analog Extruder Input Connection Diagram –

Extrusion - Proportional

.

882.01749.00 | 33 of 93 |