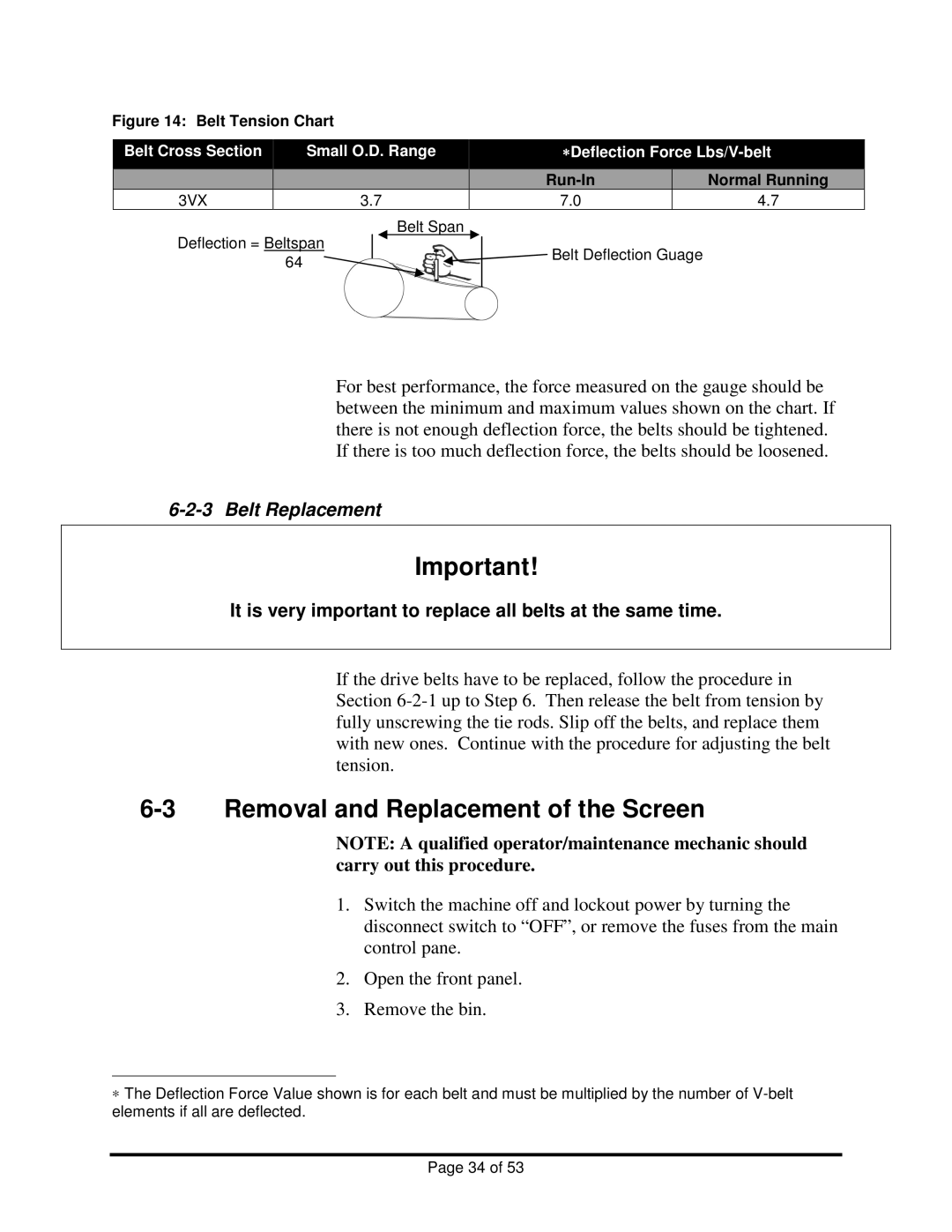

Figure 14: Belt Tension Chart

| Belt Cross Section |

|

| Small O.D. Range |

|

| ∗Deflection Force |

| |||

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Normal Running |

| |

| 3VX | 3.7 |

| 7.0 |

| 4.7 |

| ||||

| Deflection = Beltspan | Belt Span |

|

|

|

|

| ||||

|

|

| Belt Deflection Guage |

|

| ||||||

|

|

| 64 |

|

|

|

|

| |||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

For best performance, the force measured on the gauge should be between the minimum and maximum values shown on the chart. If there is not enough deflection force, the belts should be tightened. If there is too much deflection force, the belts should be loosened.

6-2-3 Belt Replacement

Important!

It is very important to replace all belts at the same time.

If the drive belts have to be replaced, follow the procedure in Section

6-3 Removal and Replacement of the Screen

NOTE: A qualified operator/maintenance mechanic should carry out this procedure.

1.Switch the machine off and lockout power by turning the disconnect switch to “OFF”, or remove the fuses from the main control pane.

2.Open the front panel.

3.Remove the bin.

∗The Deflection Force Value shown is for each belt and must be multiplied by the number of

Page 34 of 53