24 | E n g l i s h |

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() I X .

I X .

S e t - U p &

A d j u s t m e n t

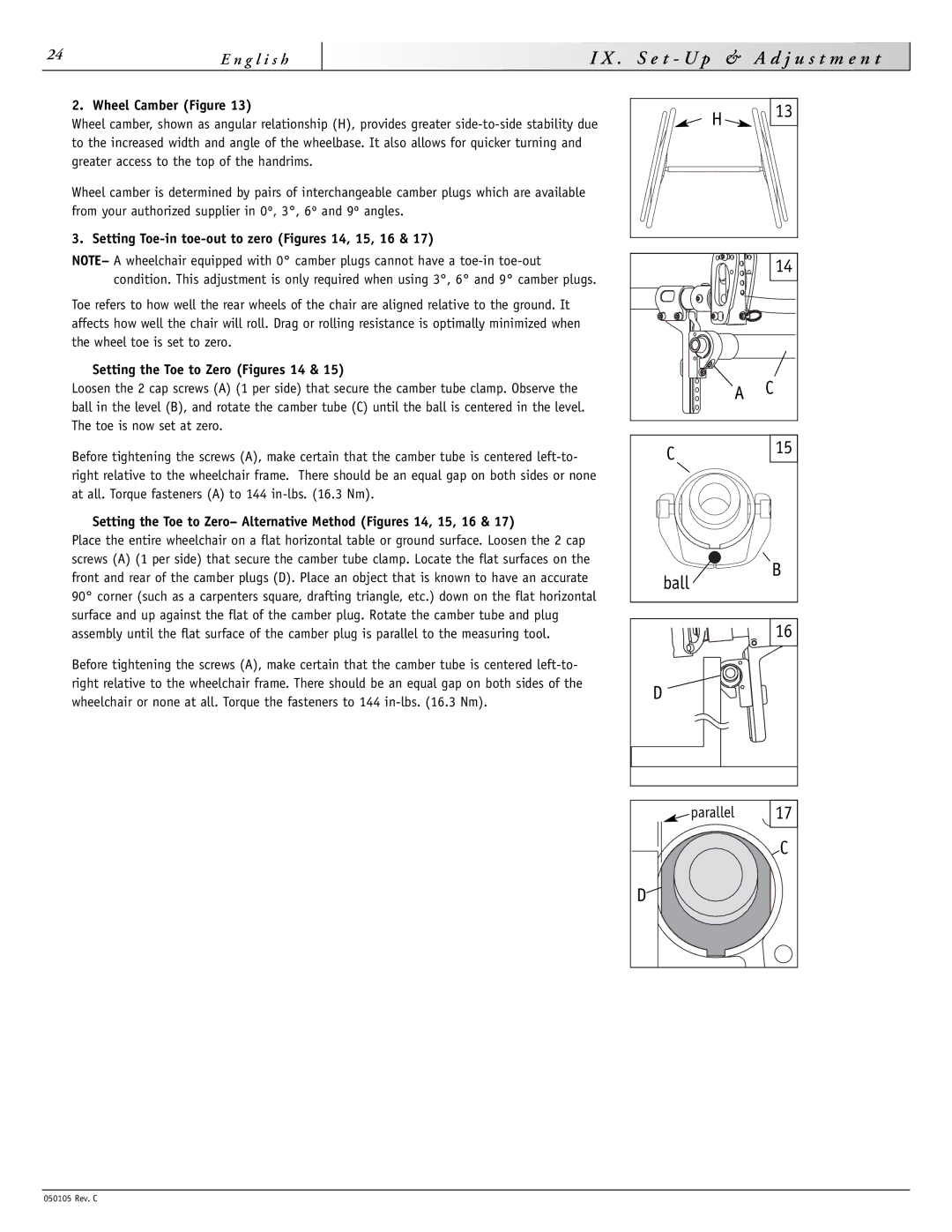

2. Wheel Camber (Figure 13)

Wheel camber, shown as angular relationship (H), provides greater

Wheel camber is determined by pairs of interchangeable camber plugs which are available from your authorized supplier in 0º, 3°, 6º and 9º angles.

3. Setting Toe-in toe-out to zero (Figures 14, 15, 16 & 17)

NOTE– A wheelchair equipped with 0° camber plugs cannot have a

Toe refers to how well the rear wheels of the chair are aligned relative to the ground. It affects how well the chair will roll. Drag or rolling resistance is optimally minimized when the wheel toe is set to zero.

Setting the Toe to Zero (Figures 14 & 15)

Loosen the 2 cap screws (A) (1 per side) that secure the camber tube clamp. Observe the ball in the level (B), and rotate the camber tube (C) until the ball is centered in the level. The toe is now set at zero.

Before tightening the screws (A), make certain that the camber tube is centered

Setting the Toe to Zero– Alternative Method (Figures 14, 15, 16 & 17)

Place the entire wheelchair on a flat horizontal table or ground surface. Loosen the 2 cap screws (A) (1 per side) that secure the camber tube clamp. Locate the flat surfaces on the front and rear of the camber plugs (D). Place an object that is known to have an accurate 90° corner (such as a carpenters square, drafting triangle, etc.) down on the flat horizontal surface and up against the flat of the camber plug. Rotate the camber tube and plug assembly until the flat surface of the camber plug is parallel to the measuring tool.

Before tightening the screws (A), make certain that the camber tube is centered

H | 13 |

| |

| 14 |

A | C |

C | 15 |

| |

ball | B |

| |

| 16 |

D |

|

parallel | 17 |

| C |

D |

|

050105 Rev. C