Operational Theory | BDS 3960 | |

|

|

|

|

|

|

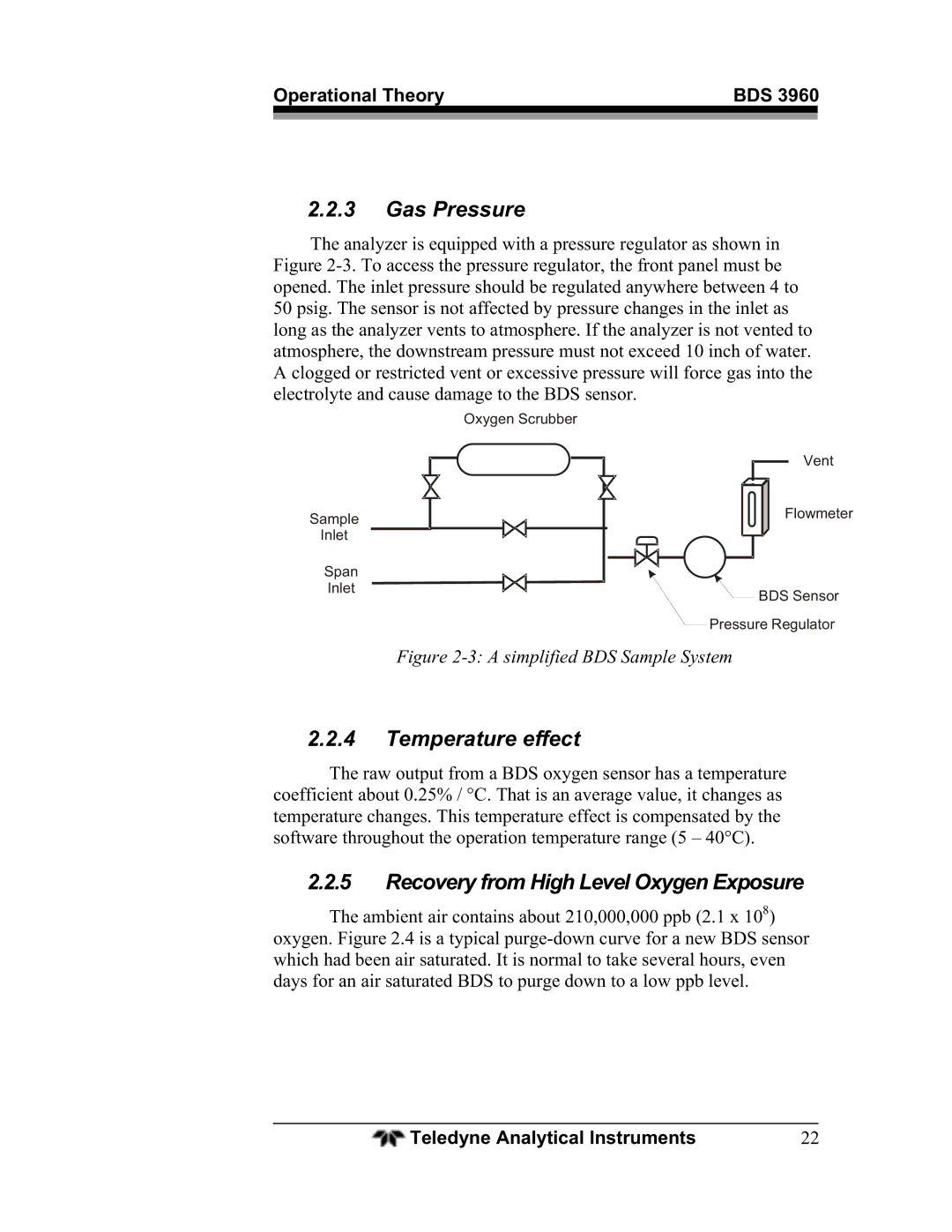

2.2.3Gas Pressure

The analyzer is equipped with a pressure regulator as shown in Figure

| Oxygen Scrubber | ||||||||||

|

|

|

|

|

|

|

|

|

|

| Vent |

Sample |

|

|

|

|

|

|

|

|

|

| Flowmeter |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

Inlet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Span |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

Inlet |

|

|

|

|

|

|

|

|

| BDS Sensor | |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| Pressure Regulator | ||||||

|

|

|

|

| |||||||

Figure 2-3: A simplified BDS Sample System

2.2.4Temperature effect

The raw output from a BDS oxygen sensor has a temperature coefficient about 0.25% / °C. That is an average value, it changes as temperature changes. This temperature effect is compensated by the software throughout the operation temperature range (5 – 40°C).

2.2.5Recovery from High Level Oxygen Exposure

The ambient air contains about 210,000,000 ppb (2.1 x 108) oxygen. Figure 2.4 is a typical

Teledyne Analytical Instruments | 22 |