Maintenance | BDS 3960 | |

|

|

|

|

|

|

3.After the sensor has been purged for at least two weeks and the baseline is stable, monitor the oxygen reading and ambient temperature over a minimum period of 24 hours.

Take the maximum and minimum oxygen readings, and the maximum and minimum temperature readings.

4.Calculate the coefficient using the relation:

Coefficient = (O2 max - O2 min) ÷ (Temp max - Temp min)

For example:

In a 24 hour run:

O2 max = 3.55 ppb

O2 min = 1.75 ppb

Temp max = 24.5 degrees C.

Temp min = 22.1 degrees C.

Coefficient =

This value is currently set to zero, since the sensor is temperature controlled and should be left at zero unless qualified personnel give instructions to change it.

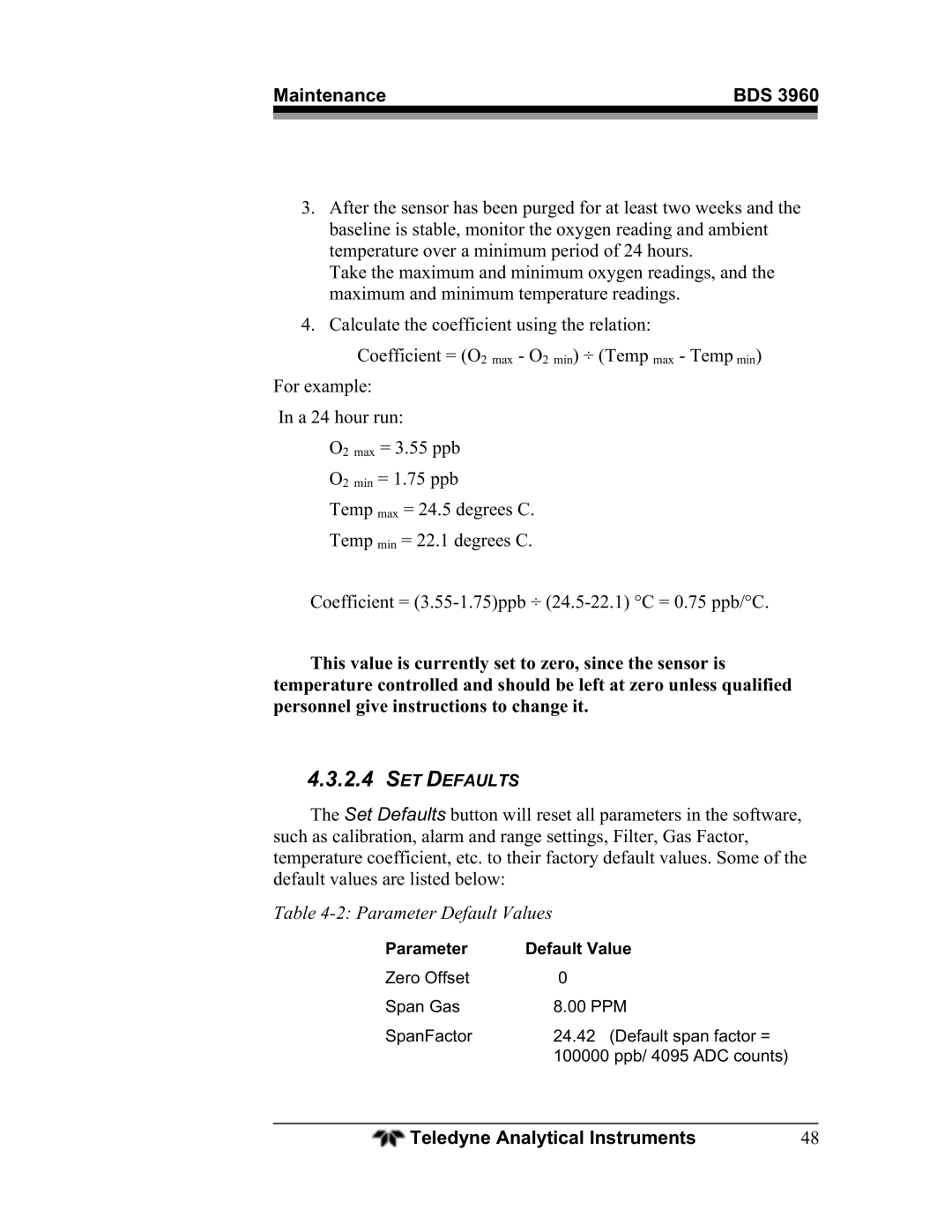

4.3.2.4SET DEFAULTS

The Set Defaults button will reset all parameters in the software, such as calibration, alarm and range settings, Filter, Gas Factor, temperature coefficient, etc. to their factory default values. Some of the default values are listed below:

Table 4-2: Parameter Default Values

Parameter | Default Value |

Zero Offset | 0 |

Span Gas | 8.00 PPM |

SpanFactor | 24.42 (Default span factor = |

| 100000 ppb/ 4095 ADC counts) |

Teledyne Analytical Instruments | 48 |