period two

Absorption Chiller Types

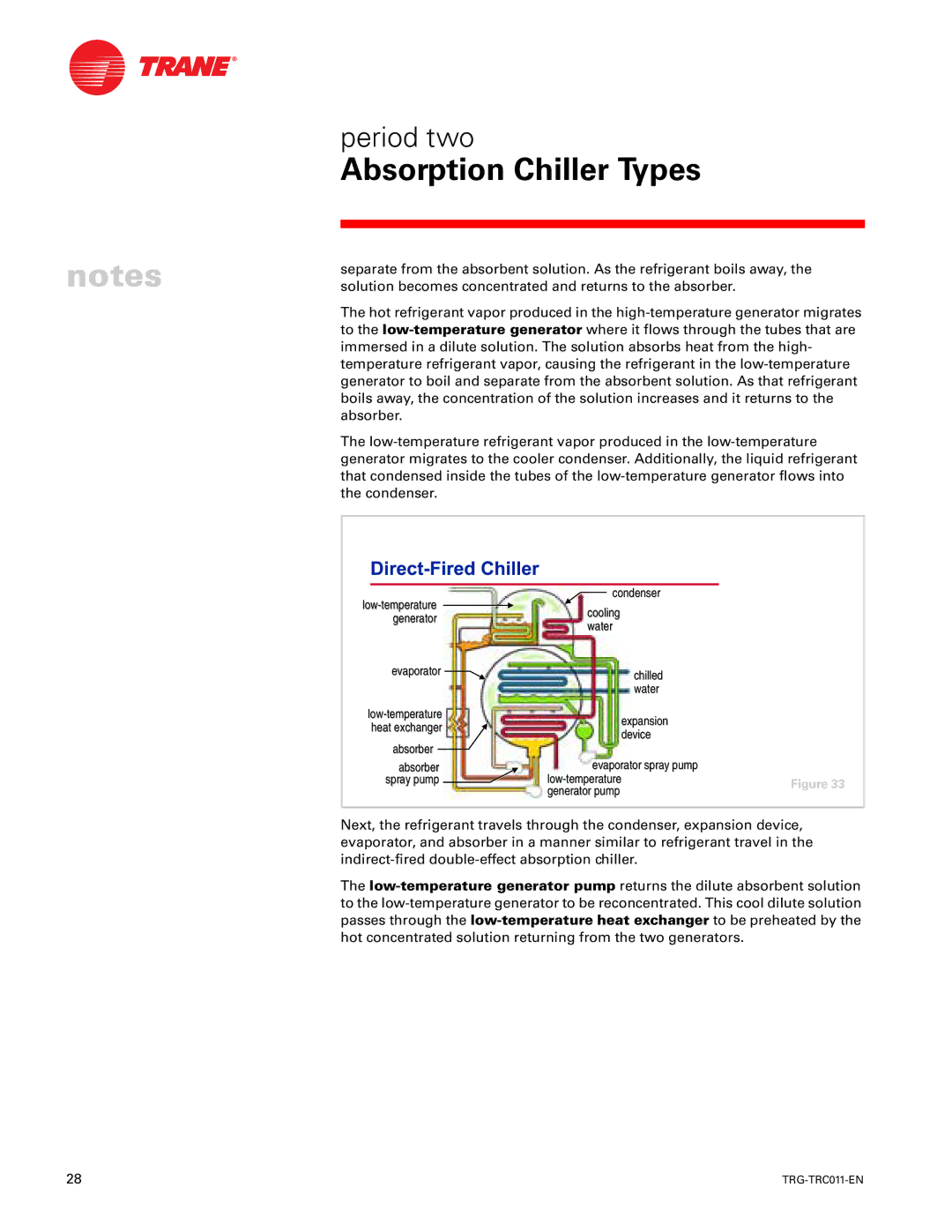

separate from the absorbent solution. As the refrigerant boils away, the solution becomes concentrated and returns to the absorber.

The hot refrigerant vapor produced in the high-temperature generator migrates to the low-temperature generator where it flows through the tubes that are immersed in a dilute solution. The solution absorbs heat from the high- temperature refrigerant vapor, causing the refrigerant in the low-temperature generator to boil and separate from the absorbent solution. As that refrigerant boils away, the concentration of the solution increases and it returns to the absorber.

The low-temperature refrigerant vapor produced in the low-temperature generator migrates to the cooler condenser. Additionally, the liquid refrigerant that condensed inside the tubes of the low-temperature generator flows into the condenser.

condenser

low-temperature | | cooling | |

| |

generator | | |

| water | |

| | |

evaporator | | chilled | |

| | |

| | water | |

low-temperature | | expansion | |

heat exchanger | | |

| device | |

| | |

absorber | | | |

absorber | | evaporator spray pump | |

spray pump | | low-temperature | Figure 33 |

| | generator pump |

| | |

Next, the refrigerant travels through the condenser, expansion device, evaporator, and absorber in a manner similar to refrigerant travel in the indirect-fired double-effect absorption chiller.

The low-temperature generator pump returns the dilute absorbent solution to the low-temperature generator to be reconcentrated. This cool dilute solution passes through the low-temperature heat exchanger to be preheated by the hot concentrated solution returning from the two generators.