period five

Application Considerations

notes

| | | | | | | | | operate | | | | | | | | |

| | | | | | | | | absorption | | | | | | | |

| | | | | | | | | chiller | | | | | | | | | |

load | | operate | | | | | | | | | | | | | | | operate |

cooling | | electric | | | | | | | | | | | | | | | electric |

| chiller | | | | | | | | | | | | | | | chiller |

| | | | | | | | | | | | | | | | | | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 11 12 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 11 12 |

on-peak

Combination Chiller Plants

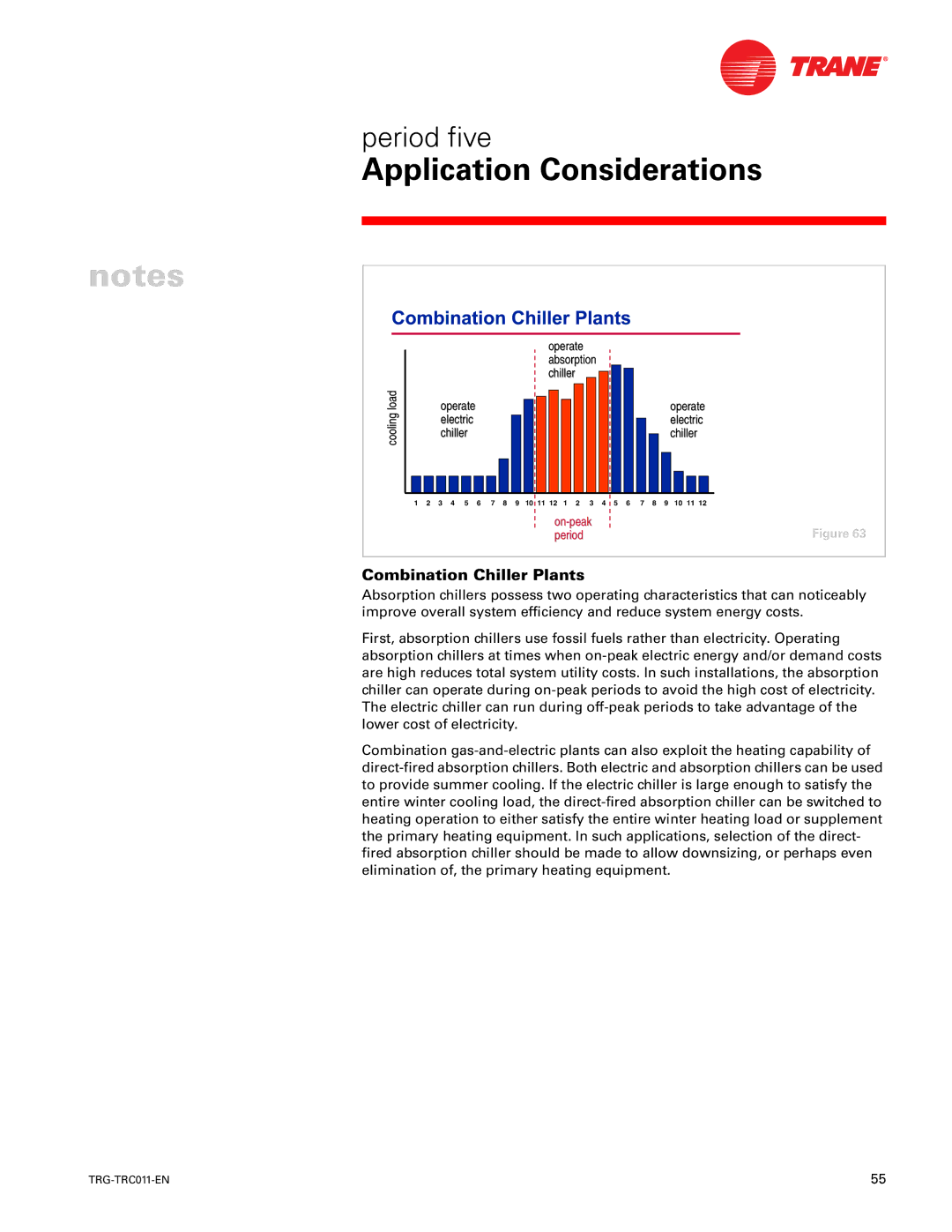

Absorption chillers possess two operating characteristics that can noticeably improve overall system efficiency and reduce system energy costs.

First, absorption chillers use fossil fuels rather than electricity. Operating absorption chillers at times when on-peak electric energy and/or demand costs are high reduces total system utility costs. In such installations, the absorption chiller can operate during on-peak periods to avoid the high cost of electricity. The electric chiller can run during off-peak periods to take advantage of the lower cost of electricity.

Combination gas-and-electric plants can also exploit the heating capability of direct-fired absorption chillers. Both electric and absorption chillers can be used to provide summer cooling. If the electric chiller is large enough to satisfy the entire winter cooling load, the direct-fired absorption chiller can be switched to heating operation to either satisfy the entire winter heating load or supplement the primary heating equipment. In such applications, selection of the direct- fired absorption chiller should be made to allow downsizing, or perhaps even elimination of, the primary heating equipment.