period six

Review

notes

and vapor refrigerant then flows into the evaporator pan, from which the evaporator spray pump continuously pumps the liquid refrigerant to be sprayed over the tubes. As heat transfers from the chilled water flowing through the tubes to the cooler refrigerant, the refrigerant boils (vaporizes) and the resulting refrigerant vapor is drawn into the absorber.

Inside the absorber, the refrigerant vapor is absorbed by the lithium bromide solution, releasing heat to the cooling water which is circulated through the tubes. Absorption of the refrigerant vapor creates a low pressure area within the absorber, inducing a continuous flow of refrigerant from the evaporator to the absorber. The absorber spray pump mixes concentrated absorbent solution (returning from the generator) with dilute solution (from inside the absorber) and delivers this intermediate solution to the absorber sprays. The lithium bromide solution becomes diluted as it absorbs the refrigerant. To complete the cycle, the generator pump continuously returns the dilute absorbent solution to the generator to be reconcentrated. This cool dilute solution passes through a heat exchanger to be preheated by the hot concentrated solution returning from the generator.

Figure 70

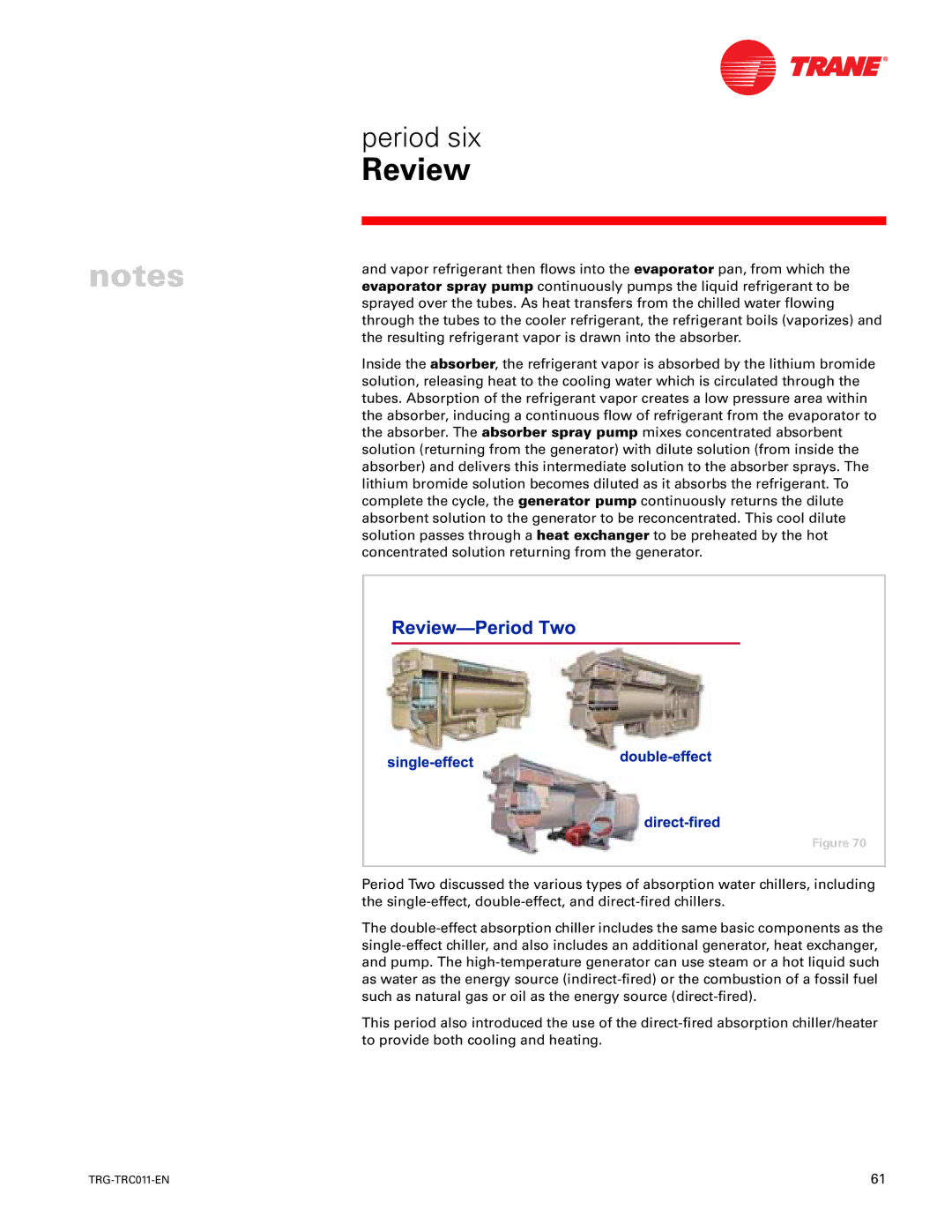

Period Two discussed the various types of absorption water chillers, including the

The

This period also introduced the use of the

61 |