period three

Capacity Control

notes

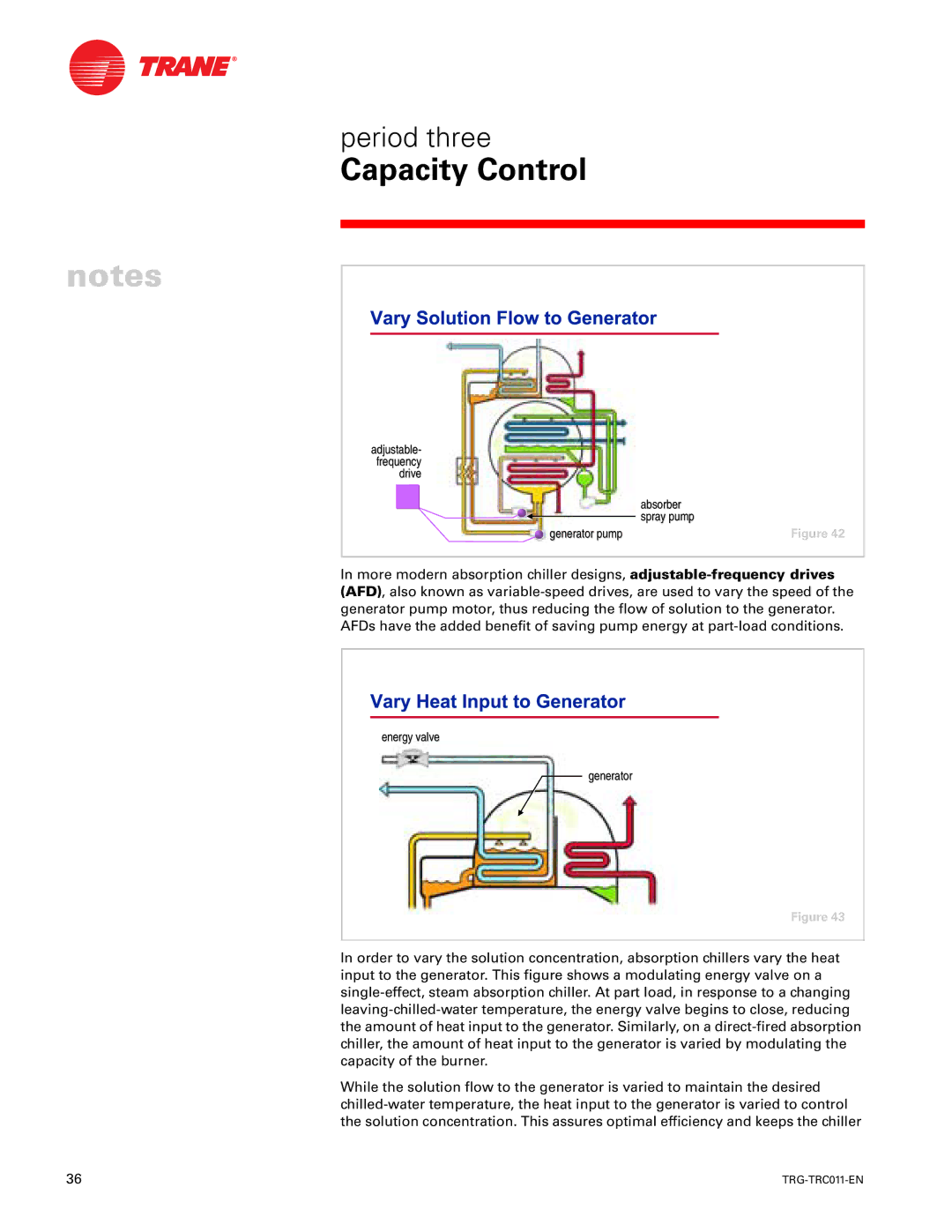

adjustable- frequency drive

| absorber |

| spray pump |

generator pump | Figure 42 |

In more modern absorption chiller designs, adjustable-frequency drives (AFD), also known as variable-speed drives, are used to vary the speed of the generator pump motor, thus reducing the flow of solution to the generator. AFDs have the added benefit of saving pump energy at part-load conditions.

energy valve

generator

Figure 43

In order to vary the solution concentration, absorption chillers vary the heat input to the generator. This figure shows a modulating energy valve on a single-effect, steam absorption chiller. At part load, in response to a changing leaving-chilled-water temperature, the energy valve begins to close, reducing the amount of heat input to the generator. Similarly, on a direct-fired absorption chiller, the amount of heat input to the generator is varied by modulating the capacity of the burner.

While the solution flow to the generator is varied to maintain the desired chilled-water temperature, the heat input to the generator is varied to control the solution concentration. This assures optimal efficiency and keeps the chiller