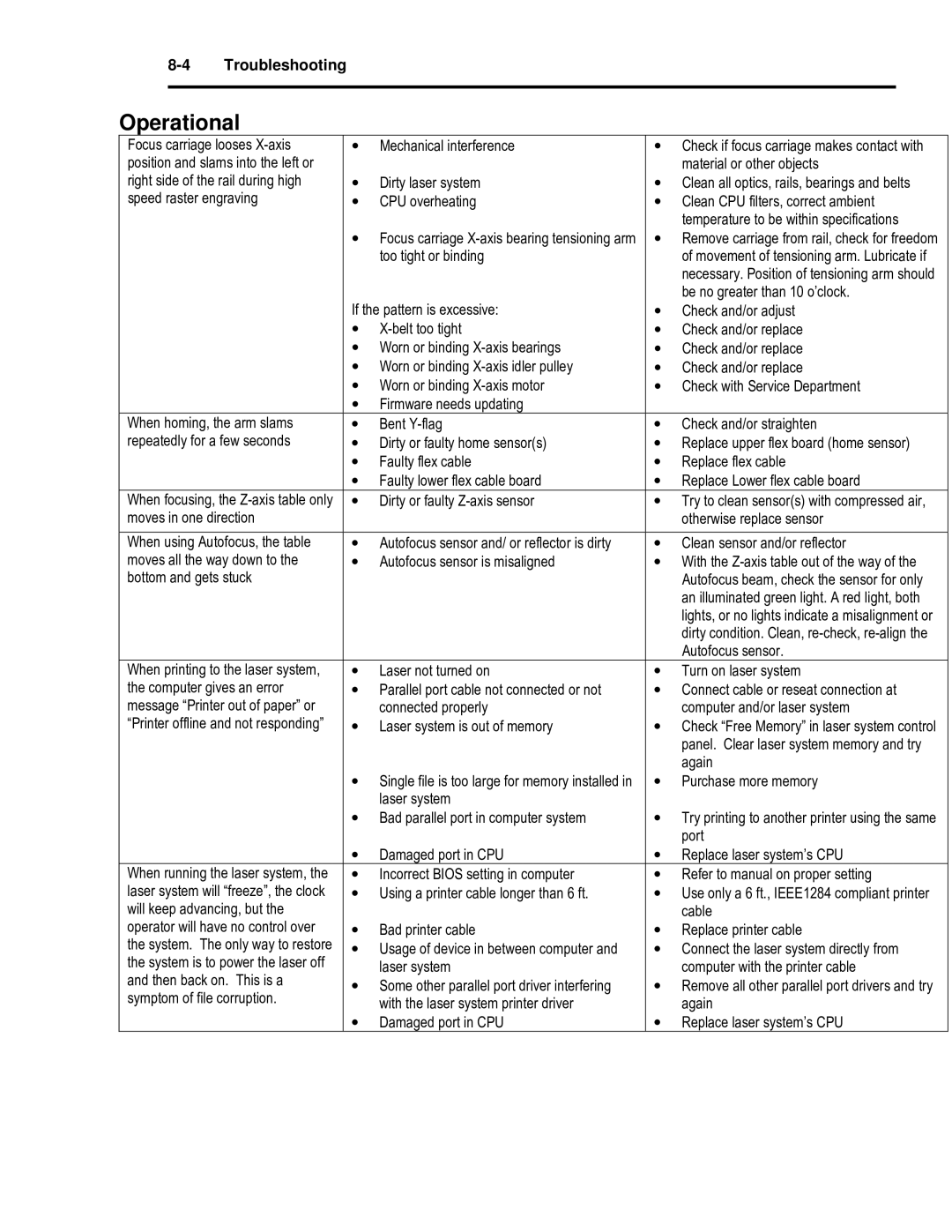

8-4 Troubleshooting

Operational

Focus carriage looses | • | Mechanical interference | • Check if focus carriage makes contact with | ||

position and slams into the left or |

|

|

| material or other objects | |

right side of the rail during high | • | Dirty laser system | • Clean all optics, rails, bearings and belts | ||

speed raster engraving | • | CPU overheating | • Clean CPU filters, correct ambient | ||

|

|

|

| temperature to be within specifications | |

| • Focus carriage | • Remove carriage from rail, check for freedom | |||

|

| too tight or binding |

| of movement of tensioning arm. Lubricate if | |

|

|

|

| necessary. Position of tensioning arm should | |

|

|

|

| be no greater than 10 o’clock. | |

| If the pattern is excessive: | • | Check and/or adjust | ||

| • | • | Check and/or replace | ||

| • Worn or binding | • | Check and/or replace | ||

| • Worn or binding | • | Check and/or replace | ||

| • Worn or binding | • Check with Service Department | |||

| • | Firmware needs updating |

|

| |

When homing, the arm slams | • | Bent | • | Check and/or straighten | |

repeatedly for a few seconds | • | Dirty or faulty home sensor(s) | • Replace upper flex board (home sensor) | ||

| • | Faulty flex cable | • | Replace flex cable | |

| • Faulty lower flex cable board | • Replace Lower flex cable board | |||

When focusing, the | • | Dirty or faulty | • Try to clean sensor(s) with compressed air, | ||

moves in one direction |

|

|

| otherwise replace sensor | |

|

|

|

| ||

When using Autofocus, the table | • | Autofocus sensor and/ or reflector is dirty | • Clean sensor and/or reflector | ||

moves all the way down to the | • | Autofocus sensor is misaligned | • With the | ||

bottom and gets stuck |

|

|

| Autofocus beam, check the sensor for only | |

|

|

|

| an illuminated green light. A red light, both | |

|

|

|

| lights, or no lights indicate a misalignment or | |

|

|

|

| dirty condition. Clean, | |

|

|

|

| Autofocus sensor. | |

When printing to the laser system, | • | Laser not turned on | • Turn on laser system | ||

the computer gives an error | • | Parallel port cable not connected or not | • Connect cable or reseat connection at | ||

message “Printer out of paper” or |

| connected properly |

| computer and/or laser system | |

“Printer offline and not responding” | • | Laser system is out of memory | • Check “Free Memory” in laser system control | ||

|

|

|

| panel. Clear laser system memory and try | |

|

|

|

| again | |

| • Single file is too large for memory installed in | • | Purchase more memory | ||

|

| laser system |

|

| |

| • Bad parallel port in computer system | • Try printing to another printer using the same | |||

|

|

|

| port | |

| • Damaged port in CPU | • Replace laser system’s CPU | |||

When running the laser system, the | • | Incorrect BIOS setting in computer | • Refer to manual on proper setting | ||

laser system will “freeze”, the clock | • | Using a printer cable longer than 6 ft. | • Use only a 6 ft., IEEE1284 compliant printer | ||

will keep advancing, but the |

|

|

| cable | |

operator will have no control over | • | Bad printer cable | • | Replace printer cable | |

the system. The only way to restore | • | Usage of device in between computer and | • Connect the laser system directly from | ||

the system is to power the laser off | |||||

| laser system |

| computer with the printer cable | ||

and then back on. This is a |

|

| |||

• | Some other parallel port driver interfering | • Remove all other parallel port drivers and try | |||

symptom of file corruption. | |||||

| with the laser system printer driver |

| again | ||

|

|

| |||

| • Damaged port in CPU | • Replace laser system’s CPU | |||