The Ignitor Spark Module is a

TO IGNITOR

SWITCHES IGNITOR

SPARK

MODULE

Figure

TO SURFACE BURNER IGNITOR

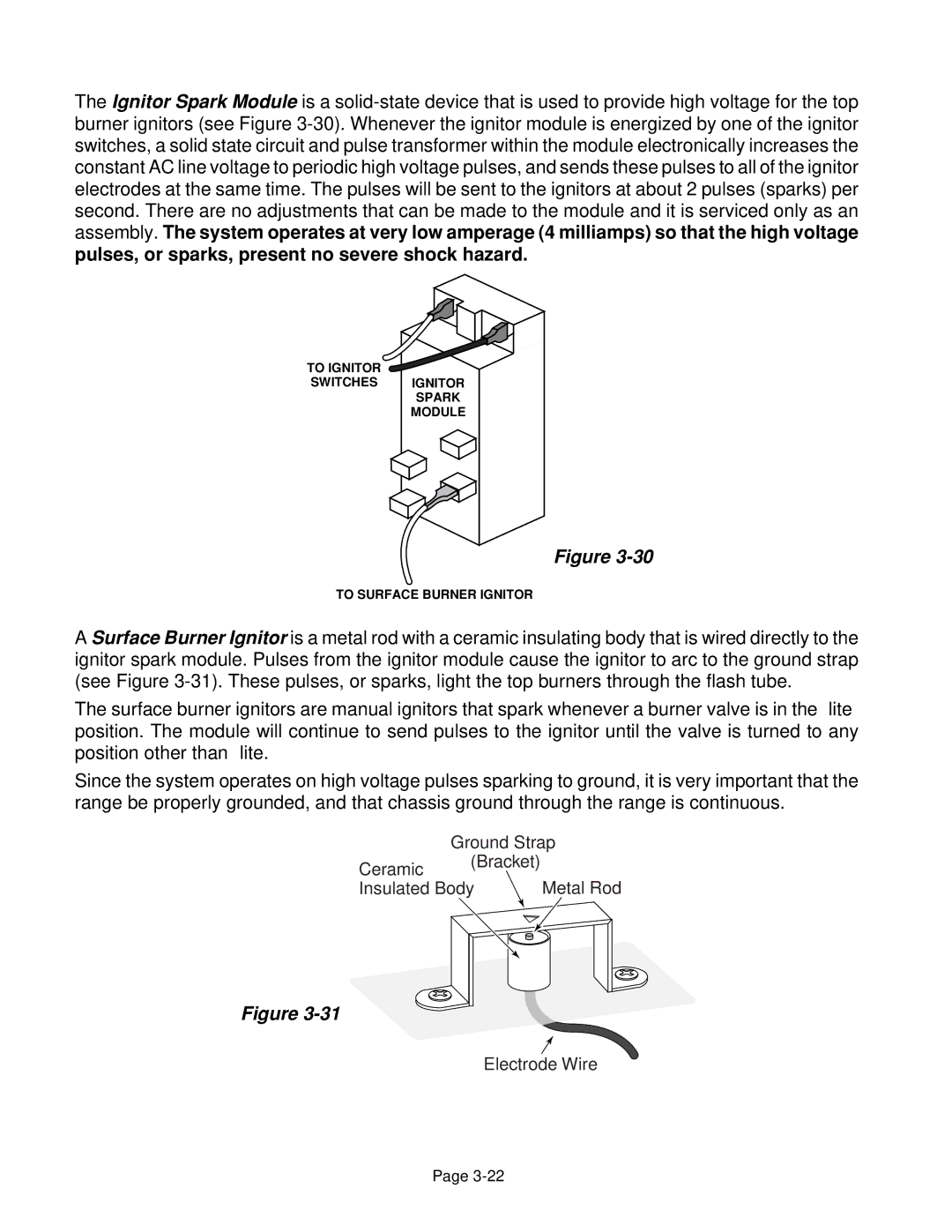

A Surface Burner Ignitor is a metal rod with a ceramic insulating body that is wired directly to the ignitor spark module. Pulses from the ignitor module cause the ignitor to arc to the ground strap (see Figure

The surface burner ignitors are manual ignitors that spark whenever a burner valve is in the “lite” position. The module will continue to send pulses to the ignitor until the valve is turned to any position other than “lite.”

Since the system operates on high voltage pulses sparking to ground, it is very important that the range be properly grounded, and that chassis ground through the range is continuous.

| Ground Strap | |

Ceramic | (Bracket) |

|

| Metal Rod | |

Insulated Body | ||

Figure

Electrode Wire

Page