VENTING

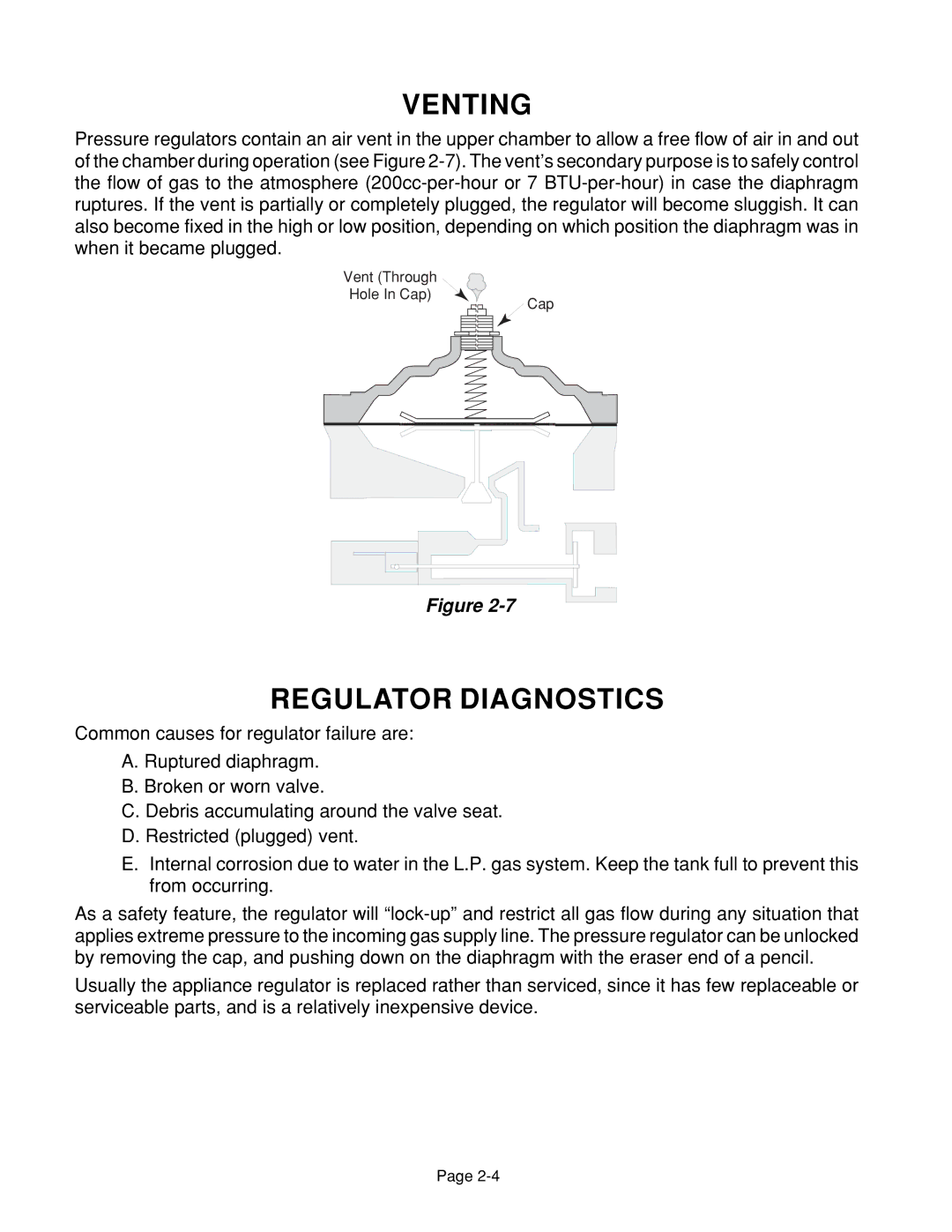

Pressure regulators contain an air vent in the upper chamber to allow a free flow of air in and out of the chamber during operation (see Figure

Vent (Through

Hole In Cap)

Cap

Figure |

REGULATOR DIAGNOSTICS

Common causes for regulator failure are:

A. Ruptured diaphragm.

B. Broken or worn valve.

C. Debris accumulating around the valve seat.

D. Restricted (plugged) vent.

E.Internal corrosion due to water in the L.P. gas system. Keep the tank full to prevent this from occurring.

As a safety feature, the regulator will

Usually the appliance regulator is replaced rather than serviced, since it has few replaceable or serviceable parts, and is a relatively inexpensive device.

Page