Gearbox leakage & Troubleshooting

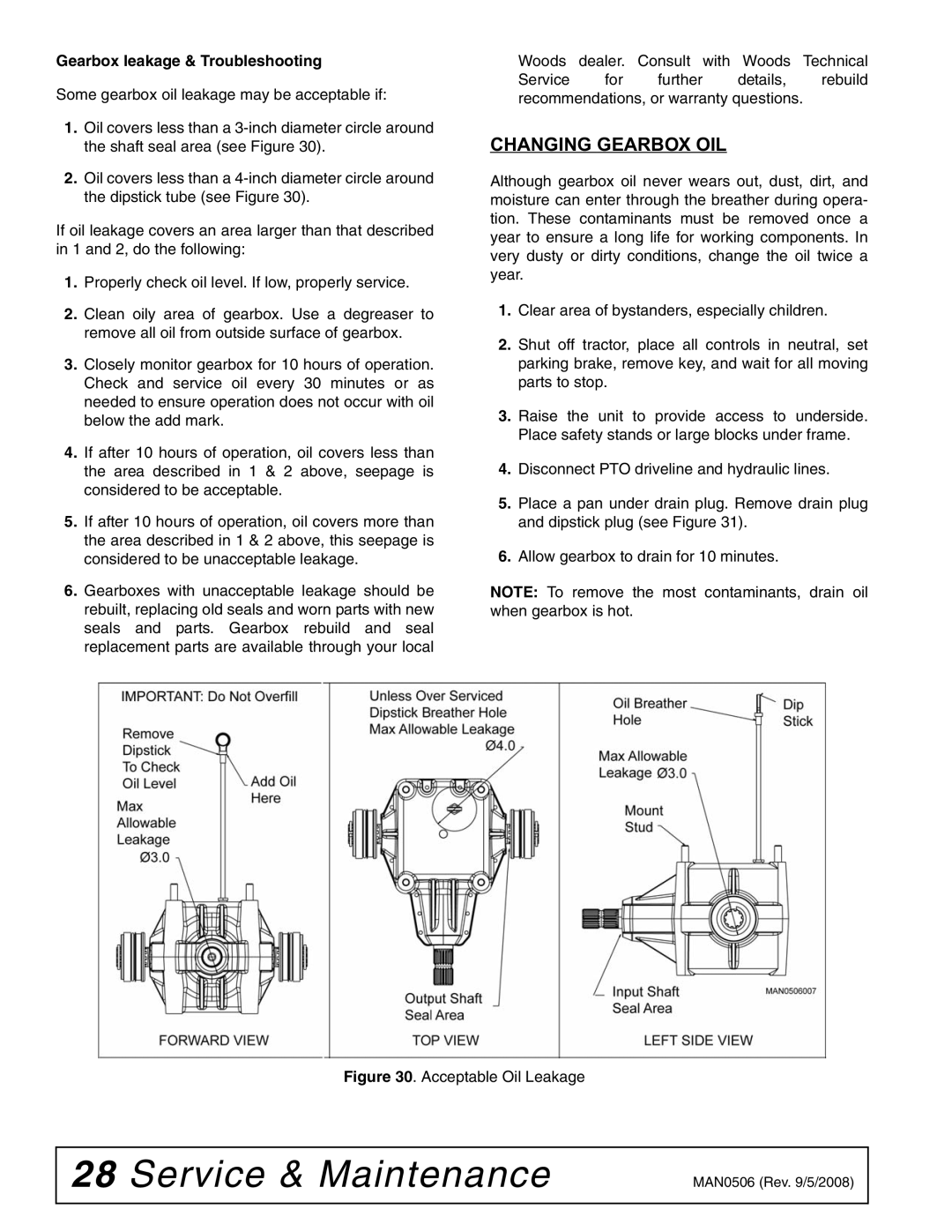

Some gearbox oil leakage may be acceptable if:

1.Oil covers less than a

2.Oil covers less than a

If oil leakage covers an area larger than that described in 1 and 2, do the following:

1.Properly check oil level. If low, properly service.

2.Clean oily area of gearbox. Use a degreaser to remove all oil from outside surface of gearbox.

3.Closely monitor gearbox for 10 hours of operation. Check and service oil every 30 minutes or as needed to ensure operation does not occur with oil below the add mark.

4.If after 10 hours of operation, oil covers less than the area described in 1 & 2 above, seepage is considered to be acceptable.

5.If after 10 hours of operation, oil covers more than the area described in 1 & 2 above, this seepage is considered to be unacceptable leakage.

6.Gearboxes with unacceptable leakage should be rebuilt, replacing old seals and worn parts with new seals and parts. Gearbox rebuild and seal replacement parts are available through your local

Woods dealer. Consult with Woods Technical

Service for further details, rebuild recommendations, or warranty questions.

CHANGING GEARBOX OIL

Although gearbox oil never wears out, dust, dirt, and moisture can enter through the breather during opera- tion. These contaminants must be removed once a year to ensure a long life for working components. In very dusty or dirty conditions, change the oil twice a year.

1.Clear area of bystanders, especially children.

2.Shut off tractor, place all controls in neutral, set parking brake, remove key, and wait for all moving parts to stop.

3.Raise the unit to provide access to underside. Place safety stands or large blocks under frame.

4.Disconnect PTO driveline and hydraulic lines.

5.Place a pan under drain plug. Remove drain plug and dipstick plug (see Figure 31).

6.Allow gearbox to drain for 10 minutes.

NOTE: To remove the most contaminants, drain oil when gearbox is hot.

Figure 30. Acceptable Oil Leakage

28 Service & Maintenance | MAN0506 (Rev. 9/5/2008) |

|

|