Technical Service for

Follow the procedure below if rotor removal or replace- ment is required.

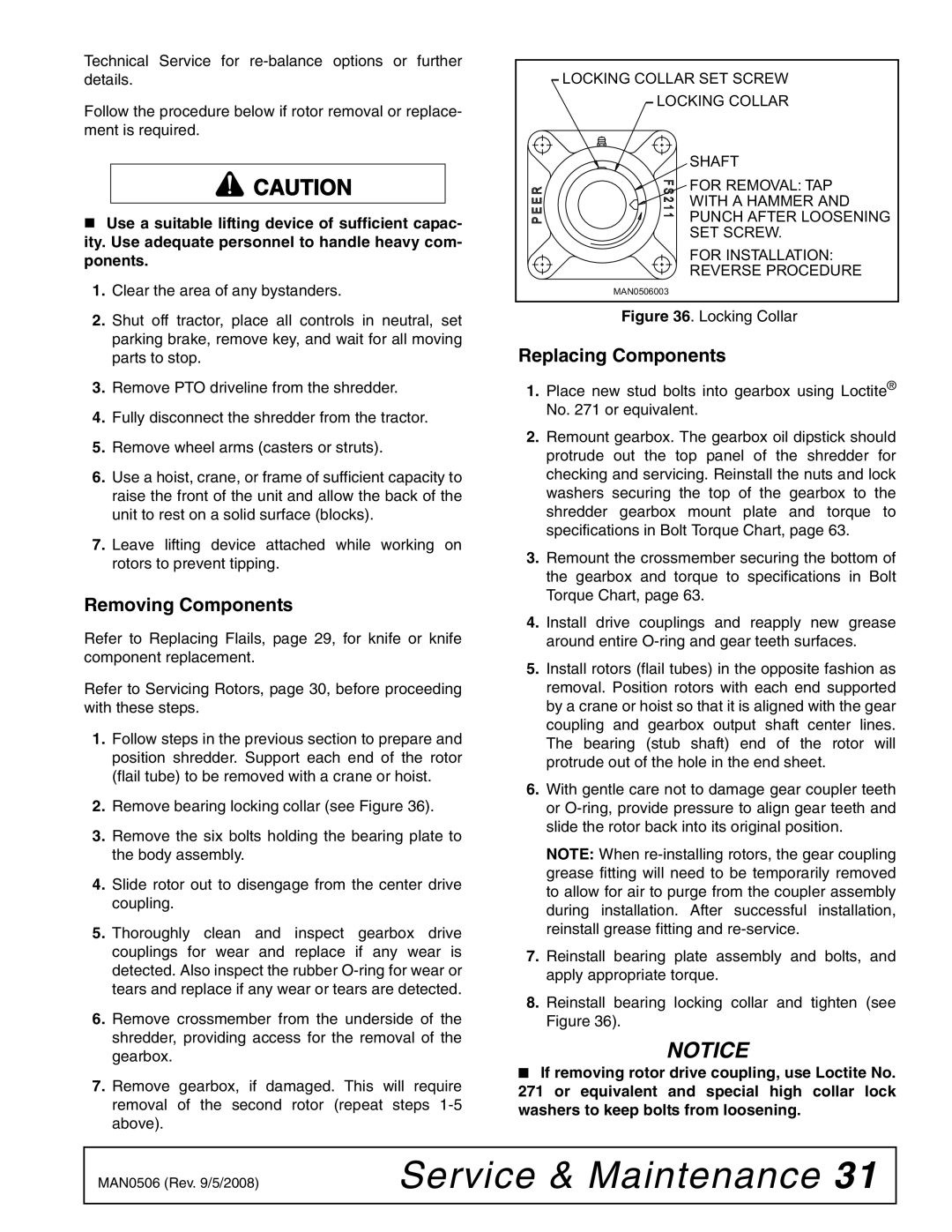

LOCKING COLLAR SET SCREW

LOCKING COLLAR

![]() CAUTION

CAUTION

Use a suitable lifting device of sufficient capac- |

ity. Use adequate personnel to handle heavy com- |

ponents. |

1. Clear the area of any bystanders. |

P E E R | F S 2 1 1 |

| MAN0506003 |

SHAFT

FOR REMOVAL: TAP

WITH A HAMMER AND PUNCH AFTER LOOSENING SET SCREW.

FOR INSTALLATION: REVERSE PROCEDURE

2. | Shut off tractor, place all controls in neutral, set |

| parking brake, remove key, and wait for all moving |

| parts to stop. |

3. | Remove PTO driveline from the shredder. |

4. | Fully disconnect the shredder from the tractor. |

5. | Remove wheel arms (casters or struts). |

6. | Use a hoist, crane, or frame of sufficient capacity to |

| raise the front of the unit and allow the back of the |

| unit to rest on a solid surface (blocks). |

7. | Leave lifting device attached while working on |

| rotors to prevent tipping. |

Removing Components

Refer to Replacing Flails, page 29, for knife or knife component replacement.

Refer to Servicing Rotors, page 30, before proceeding with these steps.

1.Follow steps in the previous section to prepare and position shredder. Support each end of the rotor (flail tube) to be removed with a crane or hoist.

2.Remove bearing locking collar (see Figure 36).

3.Remove the six bolts holding the bearing plate to the body assembly.

4.Slide rotor out to disengage from the center drive coupling.

5.Thoroughly clean and inspect gearbox drive couplings for wear and replace if any wear is detected. Also inspect the rubber

6.Remove crossmember from the underside of the shredder, providing access for the removal of the gearbox.

7.Remove gearbox, if damaged. This will require removal of the second rotor (repeat steps

Figure 36. Locking Collar

Replacing Components

1.Place new stud bolts into gearbox using Loctite® No. 271 or equivalent.

2.Remount gearbox. The gearbox oil dipstick should protrude out the top panel of the shredder for checking and servicing. Reinstall the nuts and lock washers securing the top of the gearbox to the shredder gearbox mount plate and torque to specifications in Bolt Torque Chart, page 63.

3.Remount the crossmember securing the bottom of the gearbox and torque to specifications in Bolt Torque Chart, page 63.

4.Install drive couplings and reapply new grease around entire

5.Install rotors (flail tubes) in the opposite fashion as removal. Position rotors with each end supported by a crane or hoist so that it is aligned with the gear coupling and gearbox output shaft center lines. The bearing (stub shaft) end of the rotor will protrude out of the hole in the end sheet.

6.With gentle care not to damage gear coupler teeth or

NOTE: When

7.Reinstall bearing plate assembly and bolts, and apply appropriate torque.

8.Reinstall bearing locking collar and tighten (see Figure 36).

NOTICE

■If removing rotor drive coupling, use Loctite No. 271 or equivalent and special high collar lock washers to keep bolts from loosening.

MAN0506 (Rev. 9/5/2008) | Service & Maintenance 31 |

|

|