ASSEMBLY

DEALER SET-UP INSTRUCTIONS

Do not allow bystanders in the area when oper- ating, attaching, removing, assembling, or servic- ing equipment.

Do not handle knives with bare hands. Careless or improper handling may result in serious injury.

Keep hands and body away from pressurized lines. Use paper or cardboard, not hands or other body parts to check for leaks. Wear safety goggles. Hydraulic fluid under pressure can easily penetrate skin and will cause serious injury or death.

Make sure that all operating and service person- nel know that if hydraulic fluid penetrates skin, it must be surgically removed as soon as possible by a doctor familiar with this form of injury or gan- grene, serious injury, or death will result. CON-

TACT A PHYSICIAN IMMEDIATELY IF FLUID ENTERS SKIN OR EYES. DO NOT DELAY.

Check that all hardware is properly installed. Always tighten to torque chart specifications unless instructed otherwise in this manual.

![]() CAUTION

CAUTION

Always wear relatively tight and belted clothing to avoid getting caught in moving parts. Wear sturdy,

Use a suitable lifting device of sufficient capac- ity. Use adequate personnel to handle heavy com- ponents.

1.Open the crate and cartons containing the attaching components and mounting hardware.

2.Use the packing list to check that all parts have been shipped.

For Some Models Shipped on End

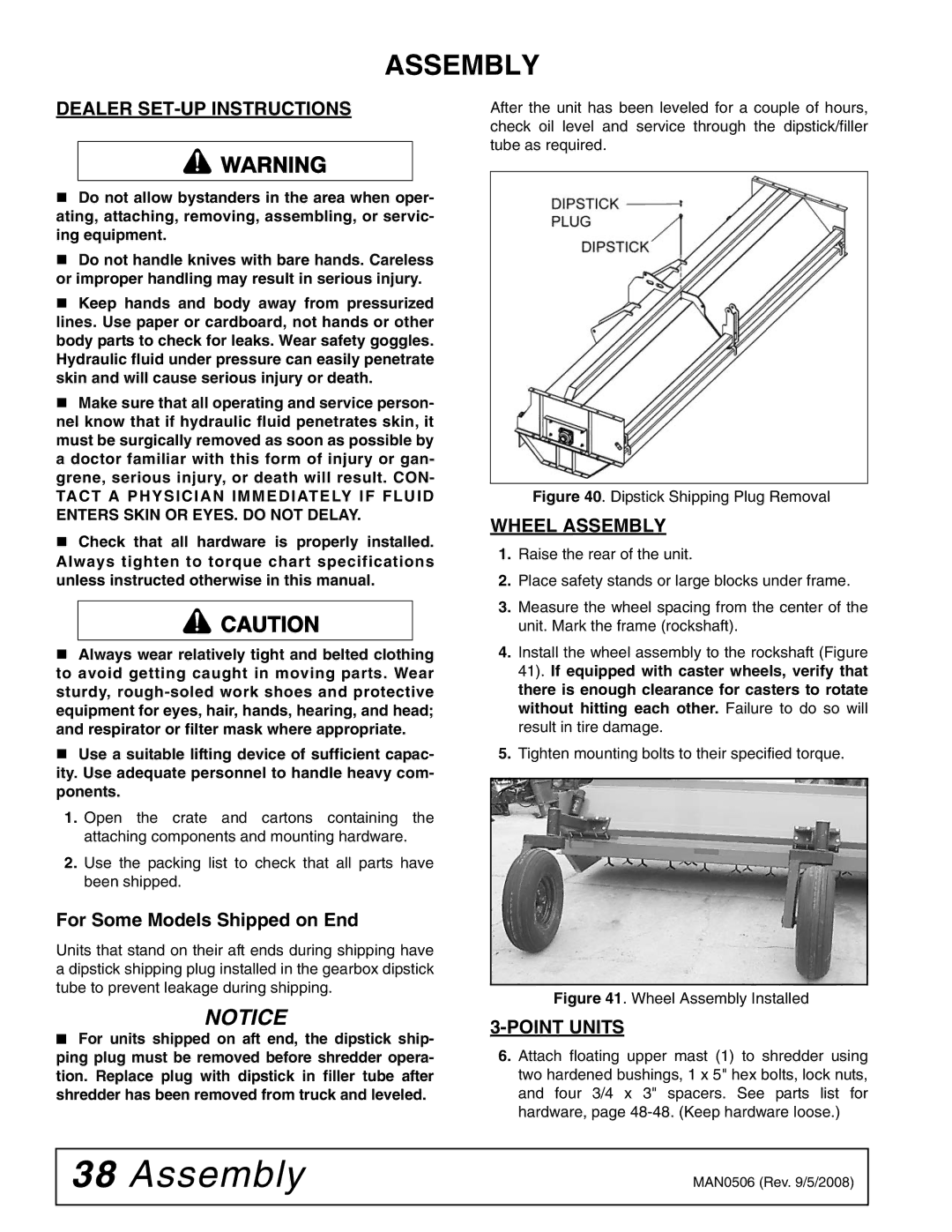

Units that stand on their aft ends during shipping have a dipstick shipping plug installed in the gearbox dipstick tube to prevent leakage during shipping.

NOTICE

■For units shipped on aft end, the dipstick ship- ping plug must be removed before shredder opera- tion. Replace plug with dipstick in filler tube after shredder has been removed from truck and leveled.

After the unit has been leveled for a couple of hours, check oil level and service through the dipstick/filler tube as required.

Figure 40. Dipstick Shipping Plug Removal

WHEEL ASSEMBLY

1.Raise the rear of the unit.

2.Place safety stands or large blocks under frame.

3.Measure the wheel spacing from the center of the unit. Mark the frame (rockshaft).

4.Install the wheel assembly to the rockshaft (Figure 41). If equipped with caster wheels, verify that there is enough clearance for casters to rotate without hitting each other. Failure to do so will result in tire damage.

5.Tighten mounting bolts to their specified torque.

Figure 41. Wheel Assembly Installed

3-POINT UNITS

6.Attach floating upper mast (1) to shredder using two hardened bushings, 1 x 5" hex bolts, lock nuts, and four 3/4 x 3" spacers. See parts list for hardware, page

38 Assembly | MAN0506 (Rev. 9/5/2008) |

|

|