W1761/W1762 12" Table Saw with Riving Knife

Adjusting Fence

The rip fence included with your Model W1761/W1762 Table Saw is designed to provide excellent ripping accu- racy when properly adjusted. There are four main adjust- ments to concern yourself with: square, height, paral- lelism, and clamping pressure. Keep in mind that these adjustments are interconnected and some

Square and Height

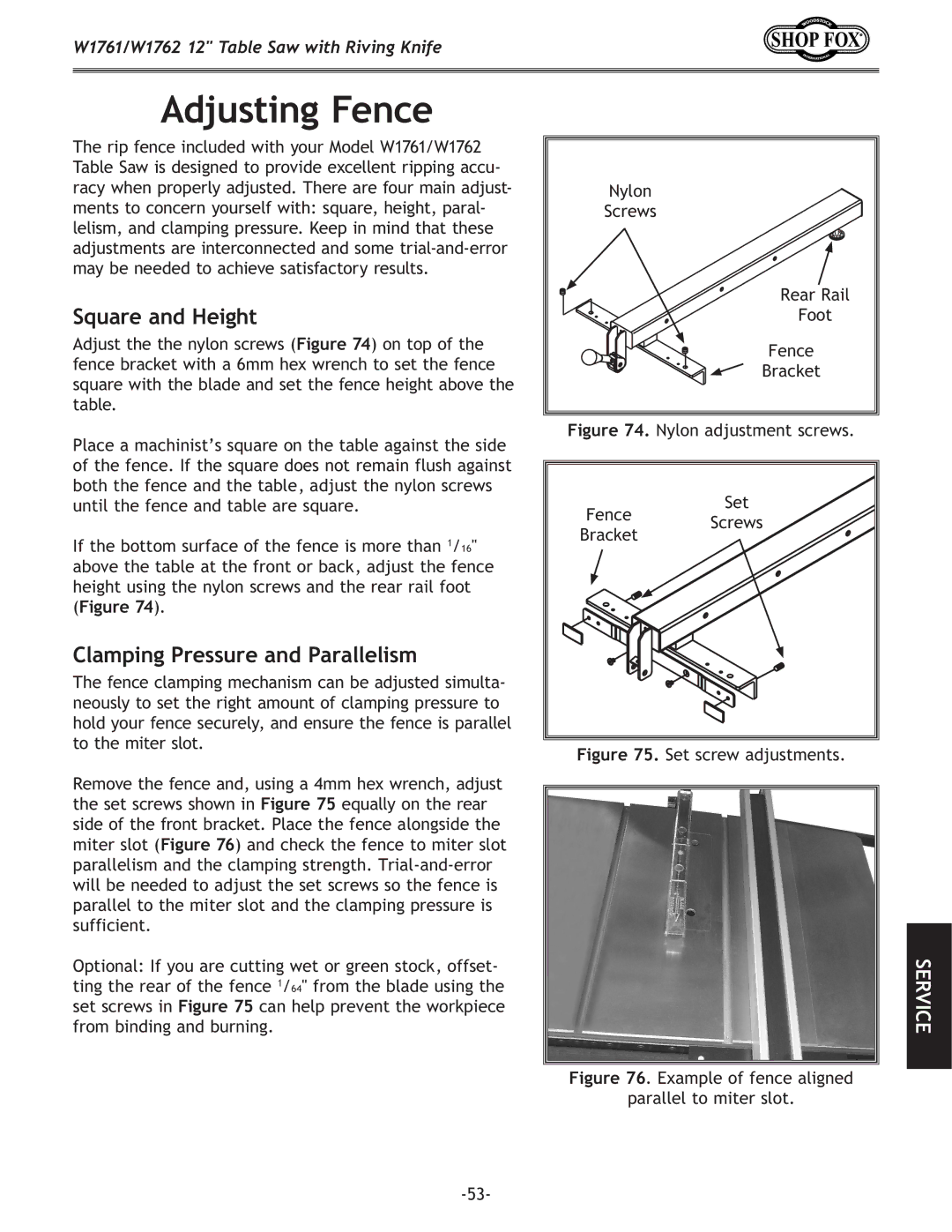

Adjust the the nylon screws (Figure 74) on top of the fence bracket with a 6mm hex wrench to set the fence square with the blade and set the fence height above the table.

Place a machinist’s square on the table against the side of the fence. If the square does not remain flush against both the fence and the table, adjust the nylon screws until the fence and table are square.

If the bottom surface of the fence is more than 1/16" above the table at the front or back, adjust the fence height using the nylon screws and the rear rail foot (Figure 74).

Clamping Pressure and Parallelism

The fence clamping mechanism can be adjusted simulta- neously to set the right amount of clamping pressure to hold your fence securely, and ensure the fence is parallel to the miter slot.

Remove the fence and, using a 4mm hex wrench, adjust the set screws shown in Figure 75 equally on the rear side of the front bracket. Place the fence alongside the miter slot (Figure 76) and check the fence to miter slot parallelism and the clamping strength.

Optional: If you are cutting wet or green stock, offset- ting the rear of the fence 1/64" from the blade using the set screws in Figure 75 can help prevent the workpiece from binding and burning.

Nylon

Screws

Rear Rail

Foot

Fence

Bracket

Figure 74. Nylon adjustment screws.

Fence | Set | |

Screws | ||

Bracket | ||

|

Figure 75. Set screw adjustments.

Figure 76. Example of fence aligned parallel to miter slot.

SERVICE