Pic 3

An optional Beeper model 850 may be fitted to sound at the start of each door movement and provide audible feedback during programming and door position calibration.

PREPARATION

Ensure that the door is free to move by hand without any stiffness or misalignment of track sections, which may cause the roller wheels to jump over the track joints. If the door movement is stiff at any point, the roller wheels should be adjusted to allow the door to be moved by hand pressure without any significant force. Any misalignment of track sections should be corrected to ensure the door runs smoothly.

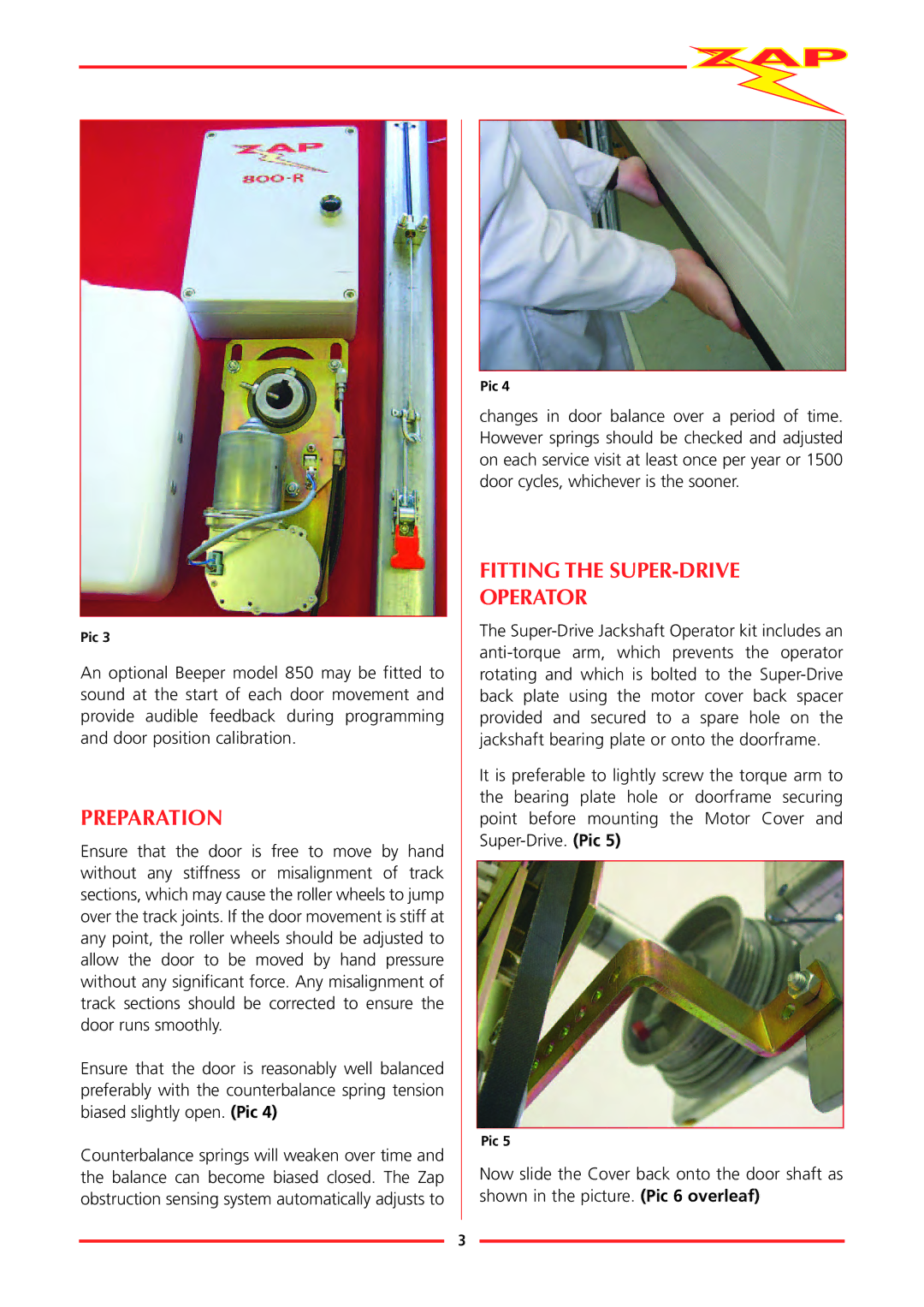

Ensure that the door is reasonably well balanced preferably with the counterbalance spring tension biased slightly open. (Pic 4)

Counterbalance springs will weaken over time and the balance can become biased closed. The Zap obstruction sensing system automatically adjusts to

Pic 4

changes in door balance over a period of time. However springs should be checked and adjusted on each service visit at least once per year or 1500 door cycles, whichever is the sooner.

FITTING THE SUPER-DRIVE

OPERATOR

The

It is preferable to lightly screw the torque arm to the bearing plate hole or doorframe securing point before mounting the Motor Cover and

Pic 5

Now slide the Cover back onto the door shaft as shown in the picture. (Pic 6 overleaf)

3