GasAdjustable

SupplyRegulator

MFC

DryCal

Cal=Trak

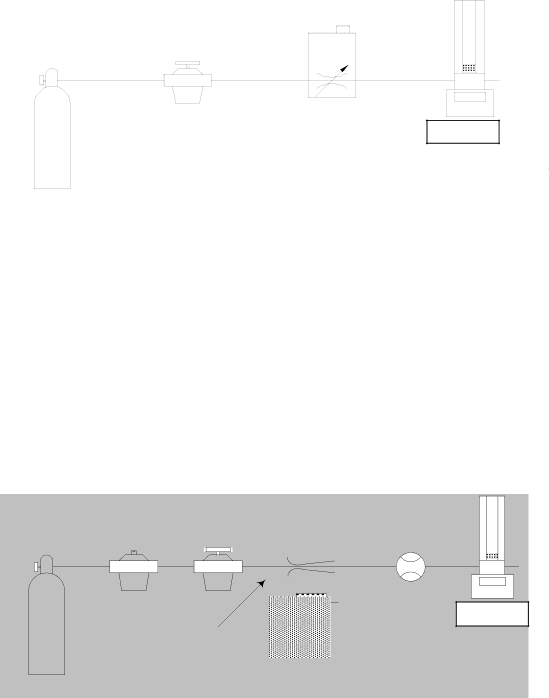

Figure 11 Setup for Calibrating MFCs

7.7Calibration of Mass Flow Meters (MFMs)

Mass flow meters can be calibrated with the setup of Figure 12, which is similar to that shown for LFE transfer standards. Again, the flow must not be affected significantly by the Cal=Trak’s cyclic pressure increase. This can be achieved by use of a sonic nozzle as the stable flow source, or by feeding a fixed restrictor with a precisely regulated pressure of more than 200 kPa. (At 200 kPa [30 PSI], the dynamic flow decrease caused by the piston’s weight will be about 0.05%.) Alternately, a stable mass flow controller may be used to maintain specific flows into the MFM under test. In this scenario, the MFC will function as a pressure stabilizer and precision flow regulator with the Cal=Trak defining the accuracy of the device under test. Contact Sierra Instruments for special

If the MFM under test must be calibrated at pressure (i.e. because it is always used under pressure) then a fine resolution valve (needle valve) and a gauge should be installed between the MFM and the Cal=Trak. Adjust the valve until the pressure gauge reads the correct pressure for the MFM under test.

GasFixed Adjustable Sonic

Supply Regulator Regulator Nozzle

Flow Meter

Stable Pressure | OR Porous Plug | ||||

|

|

|

|

| |

> 200 kPa |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| OR MFC |

| |||

Figure 12 Setup for Calibrating Mass Flow Meters

Cal=TraDryCalk

7.8Calibration of Rotameters (Variable Area Flow Meters)

16