10 Installing Vent Pipe (SLP Pipe)

A. Assemble Vent Sections

To attach the first vent component to the starting collars of the appliance:

•Lock the vent components into place by sliding the pipe section onto the collar.

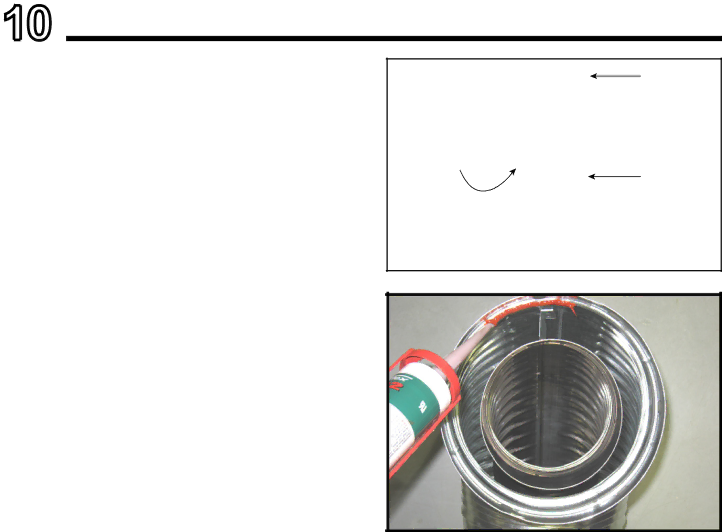

•Align the seam of the pipe and seam of collar to allow engagement. Rotate the vent component to lock into place. Use this procedure for all vent components. See Figure 10.1.

• Slide the gasket over the first vent section and place it flush to the appliance. This will prevent cold air infiltration. High temperature caulk (150 ºC minimum continuous exposure rating) may be used to hold the part in place.

•Continue adding vent components, locking each succeeding component into place.

•Ensure that each succeeding vent component is securely fitted and locked into the preceding component.

Commercial,

For Installation into a commercial,

pipe joints must be sealed with high temperature (150 ºC minimum continuous exposure rating) silicone, including the slip section that connects directly to the horizontal ter- mination cap.

•Apply a bead of silicone sealant inside the female outer pipe joint prior to joining sections. See Figure 10.2

•Only outer pipes need to be sealed. All unit collar, pipe, slip section, elbow and cap outer flues shall be sealed in this manner, unless otherwise stated.

WARNING! Risk of Fire or Explosion! DO NOT break silicone seals on slip sections. Use care when removing termination cap from slip pipe. If slip section seals are bro- ken during removal of the termination cap, vent may leak.

Note: Align seams to engage pipe, then rotate counterclockwise to lock

Figure 10.1 Adding Venting Components

Figure 10.2 High Temperature Silicone Sealant (300ºF minimum continuous exposure rating)

Heat & Glo • | 35 |