VI. Venting / Air Intake Piping

NOTICE

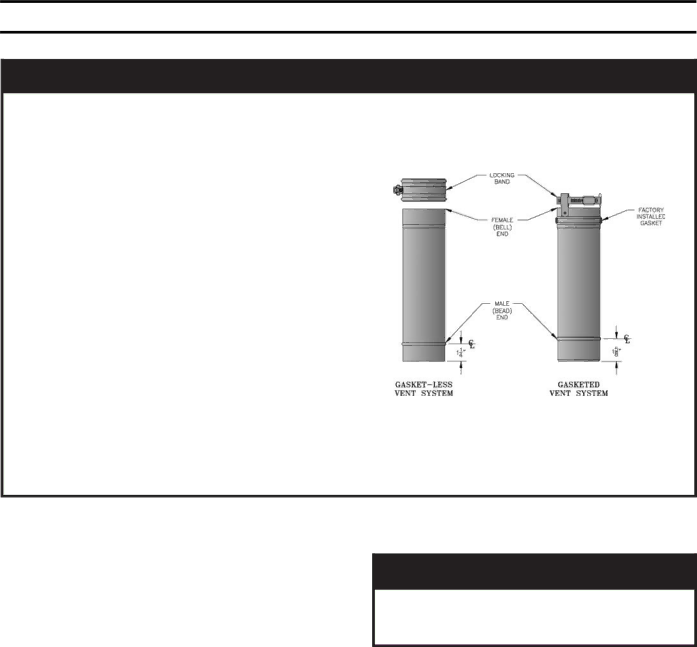

The gasketed vent system components pictured below in Figure A are being phased in and each vent component is interchangeable with the previously supplied

In the event a gasketed vent component and a

1) Any joining of vent components that involves at least one

2) The female end of a |

|

vent component always requires |

|

a clamp band, regardless of the |

|

design of the mating male vent | Figure A: Burnham Vent |

component. |

Each

A Vent Transition Kit, part number 6116302, is available that contains one clamp band and one 3 ounce tube of sealant.

A.General Guidelines.

1.Vent system installation must be in accordance with National Fuel Gas Code, ANSI Z223.1, Venting of Equipment, or applicable provisions of local building codes. Contact local building or fire officials about restrictions and installation inspection in your area.

2.This appliance requires a Special Gas Vent. The product is designed to use Burnham supplied

AL

WARNING

Do not use this boiler with galvaniz ed, 304 or 316 stainless steel or any other non

3.Vent length restrictions are based on equivalent length of vent pipe (total length of straight pipe plus equivalent length of fittings). Maximum vent length is listed in Table 6. Do not exceed maximum vent/ air intake lengths. Table 7 lists equivalent length for fittings. Do not include Vent Terminal or Vent Connector in equivalent feet calculation.

Table 6: Vent/Air Intake Length

3" Vent Pipe (Equiv. Ft.) | 4" Air Intake Pipe (Equiv. Ft.) | ||

|

|

|

|

Min. | Max. | Min. | Max. |

|

|

|

|

8 | 70 | 8 | 70 |

|

|

|

|

11