ASSEMBLY

TRACTOR PREPARATION

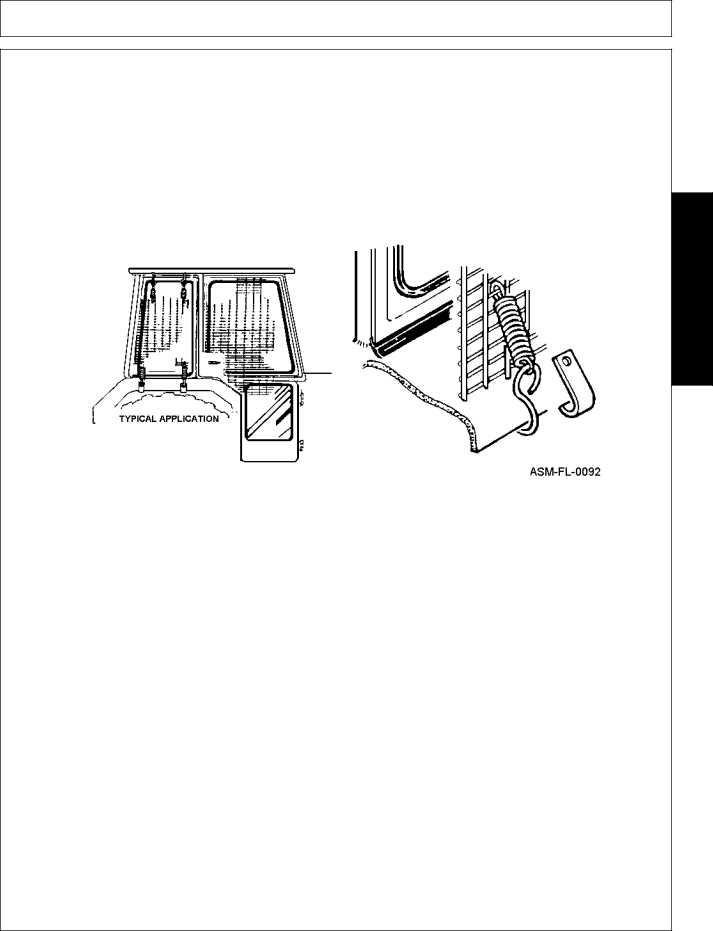

Fitting Operator Guard

A tractor fitted with a cab that has a safety glass windows should be used whenever possible. This is a basic safety precaution applicable to the use of all

Power arms are supplied with an operator guard kit (Part No. 73 13 324) which must be fitted to the tractor before commencing work.

It consists of two areas of wire mesh which can be shaped to suit and be secured against the cab window with a spring loaded hooks; the upper edge being anchored around the cab gutter and the lower edge around the mudwing.

According to the great range of cabs, it may be necessary to adapt or make brackets to secure the mesh.

If the flail is operated on a tractor that is equipped with a a safety frame or roll bar only, an additional frame must be made and fixed to the tractor onto which the guard mesh can be secured. In addition to the guard mesh, a sheet of Polycarbonate transparent glazing must be fitted to the frame to provide further operator protection. This material must also be used when the cab does not have safety glass installed.

The operator guard kit supplied is suitable for all standard applications; i.e., rear mounted on a conventional tractor. For other applications, additional mesh guarding may need to be constructed to give adequate operator protection. A guideline to follow when assessing any additional guarding that may be required is that the operator must always be looking at the flail head through the mesh when it is in any working position.

Polycarbonate transparent sheeting is an impact resistant material which can be readily sawed and shaped according to requirements. Unfortunately, it is susceptible to surface damage and scratching. Therefore, it is advisable to place the material on the inside of the window for protection. No attempt should be made to wipe the sheeting with dirt ingrained cloth.

Toughened grades of polycarbonate sheeting are available under the brand names of “Makrolon”, “Tuffak” and “Lexan”.

In case of difficulty in obtaining this material locally, contact F.W. McConnell Ltd. through your normal dealer.

PA91 03/09 | Assembly Section |

© 2009 Alamo Group Inc.