:ANAPURNA L/XL | OPERATOR MANUAL |

5.5.Printing heads

-Ink supply by means of negative pressure:

By means of negative pressure, the ink is kept in the print heads. A too high setting will cause missing nozzles, or no ink firing at all. When the pressure is too low, the ink will leak out of the heads.

The Neg. Pressure should be set to

When using White ink:

It is possible that the Neg. Pressure needs to be tuned towards

With the white ink, a higher temperature will result in a lower viscosity (more liquid state), which can lead to ink “Pooling” underneath the print head.

“Pooling”: ink build up underneath the print head, causing nozzle failure.

As the head needs to fire drops, the fired drops are not getting through the pool of ink underneath the head. An increase of Neg. Pressure,

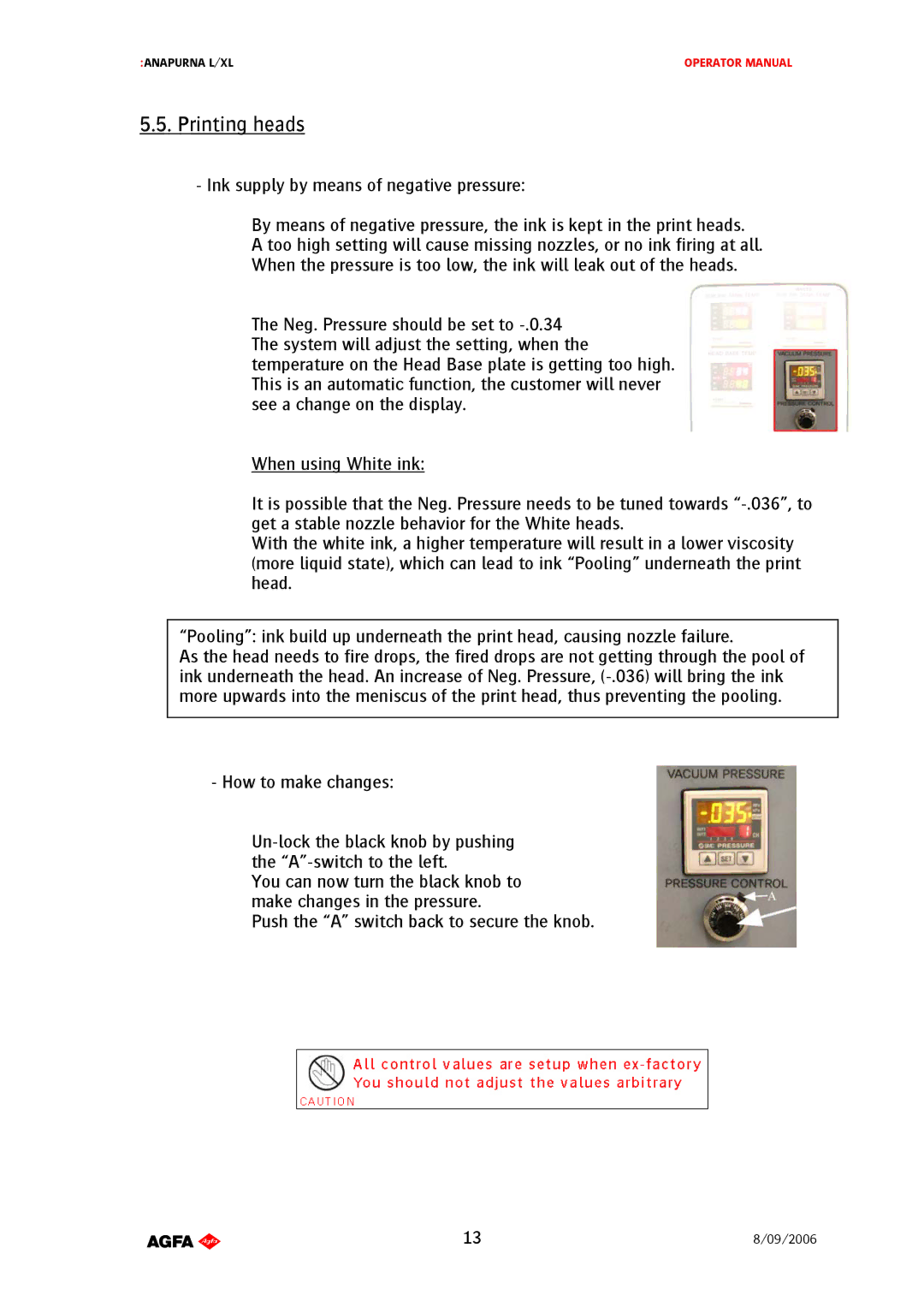

- How to make changes:

You can now turn the black knob to make changes in the pressure.

Push the “A” switch back to secure the knob.

AB]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]13]8/09/2006]