PERFORMANCE MEASUREMENTS

CONSTANT VOLTAGE POWER SUPPLY MEASUREMENTS

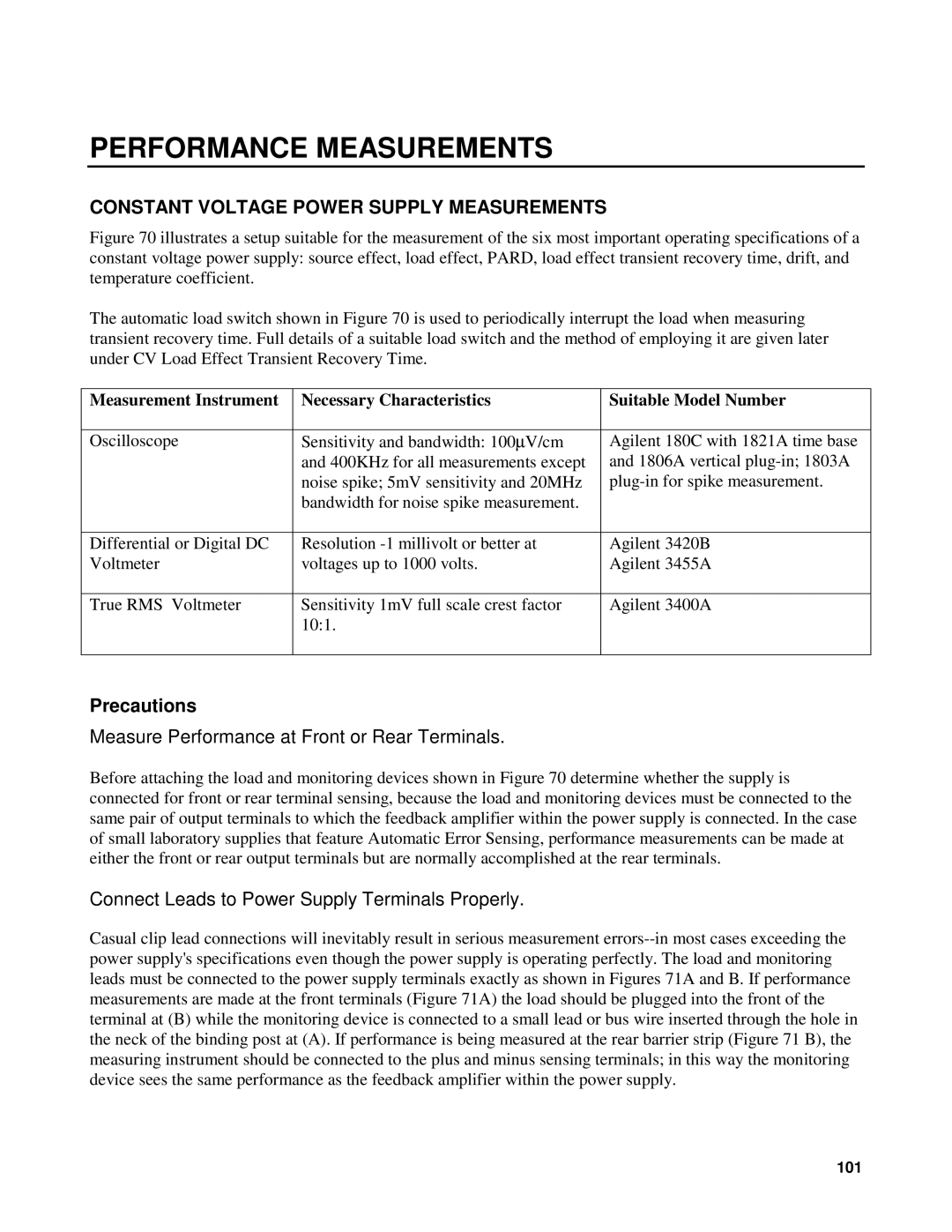

Figure 70 illustrates a setup suitable for the measurement of the six most important operating specifications of a constant voltage power supply: source effect, load effect, PARD, load effect transient recovery time, drift, and temperature coefficient.

The automatic load switch shown in Figure 70 is used to periodically interrupt the load when measuring transient recovery time. Full details of a suitable load switch and the method of employing it are given later under CV Load Effect Transient Recovery Time.

Measurement Instrument | Necessary Characteristics | Suitable Model Number |

|

|

|

Oscilloscope | Sensitivity and bandwidth: 100∝ V/cm | Agilent 180C with 1821A time base |

| and 400KHz for all measurements except | and 1806A vertical |

| noise spike; 5mV sensitivity and 20MHz | |

| bandwidth for noise spike measurement. |

|

|

|

|

Differential or Digital DC | Resolution | Agilent 3420B |

Voltmeter | voltages up to 1000 volts. | Agilent 3455A |

|

|

|

True RMS Voltmeter | Sensitivity 1mV full scale crest factor | Agilent 3400A |

| 10:1. |

|

|

|

|

Precautions

Measure Performance at Front or Rear Terminals.

Before attaching the load and monitoring devices shown in Figure 70 determine whether the supply is connected for front or rear terminal sensing, because the load and monitoring devices must be connected to the same pair of output terminals to which the feedback amplifier within the power supply is connected. In the case of small laboratory supplies that feature Automatic Error Sensing, performance measurements can be made at either the front or rear output terminals but are normally accomplished at the rear terminals.

Connect Leads to Power Supply Terminals Properly.

Casual clip lead connections will inevitably result in serious measurement

101