Some idea of how easily even the shortest leads can degrade the performance of a power supply at the load terminals can be obtained by comparing the output impedance of a

AWG (B & S) | Annealed Copper Resistance at | Nominal current rating (amps)* |

WIRE SIZE | 20°C milliohms/ft. |

|

22 | 16.1 | 5 |

20 | 10.2 | 7 |

18 | 6.39 | 10 |

16 | 4.02 | 13 |

14 | 2.53 | 20 |

12 | 1.59 | 25 |

10 | 0.999 | 40 |

8 | 0.628 | 55 |

6 | 0.395 | 80 |

4 | 0.249 | 105 |

2 | 0.156 | 140 |

0 | 0.0993 | 195 |

00 | 0.0779 | 260 |

* Single conductor in Free Air at 30° C with rubber or thermoplastic insulation

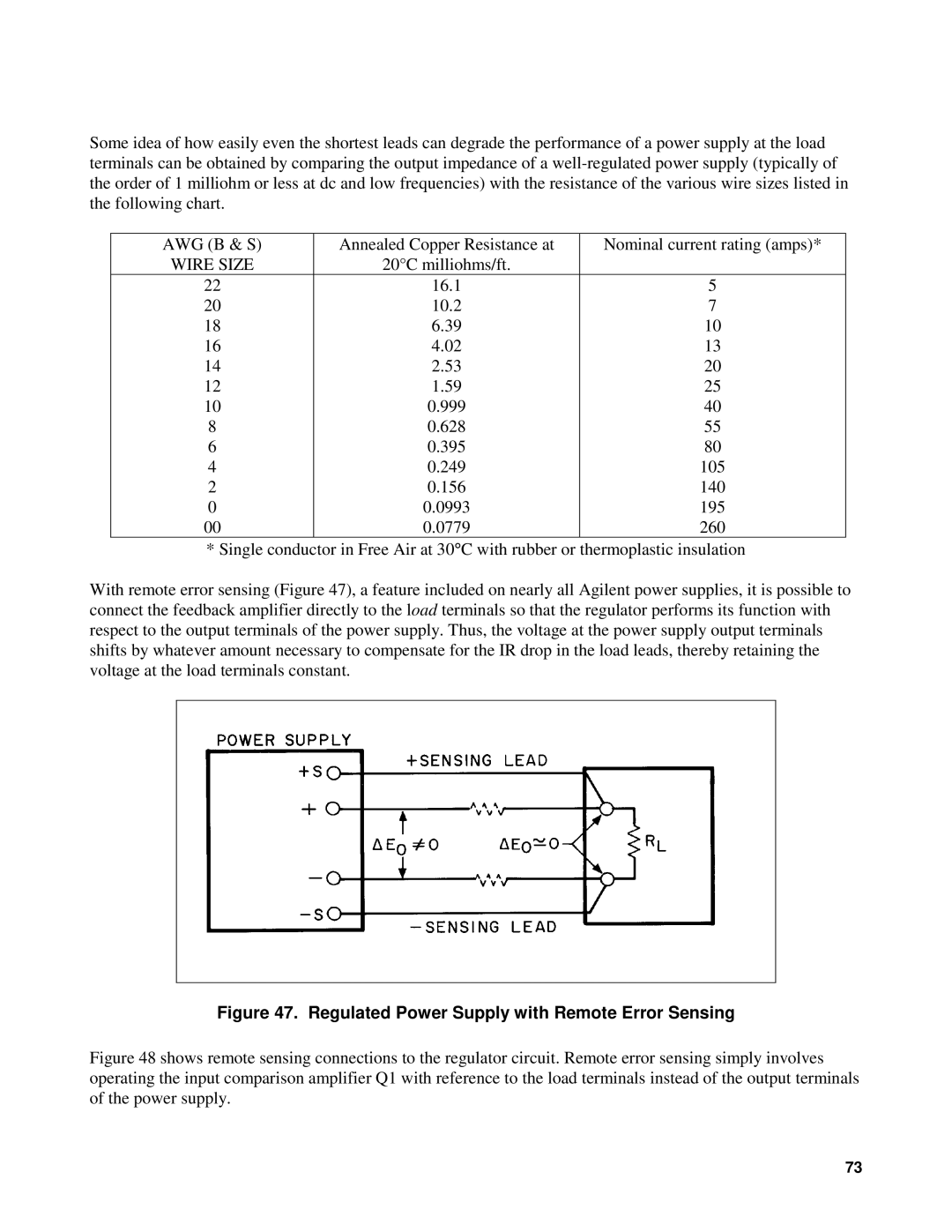

With remote error sensing (Figure 47), a feature included on nearly all Agilent power supplies, it is possible to connect the feedback amplifier directly to the load terminals so that the regulator performs its function with respect to the output terminals of the power supply. Thus, the voltage at the power supply output terminals shifts by whatever amount necessary to compensate for the IR drop in the load leads, thereby retaining the voltage at the load terminals constant.

Figure 47. Regulated Power Supply with Remote Error Sensing

Figure 48 shows remote sensing connections to the regulator circuit. Remote error sensing simply involves operating the input comparison amplifier Q1 with reference to the load terminals instead of the output terminals of the power supply.

73