Specifications and Dimensions

Electrical Installation Requirements

IMPORTANT: Electrical ratings are subject to change. Refer to serial decal for electrical ratings information specific to your machine.

WARNING

This machine must be installed, adjusted, and serviced by qualified electrical maintenance personnel familiar with the construction and operation of this type of machinery. They must also be familiar with the potential hazards involved. Failure to observe this warning may result in personal injury and/or equipment damage, and may void the warranty.

SW004

WARNING

Dangerous voltages are present in the electrical control box(es) and at the motor terminals. Only qualified personnel familiar with electrical test procedures, test equipment, and safety precautions should attempt adjustments and troubleshooting. Disconnect power from the machine and wait 3 minutes before removing the control box cover, and before attempting any service procedures.

W702

WARNING

Ensure that a ground wire from a proven earth ground is connected to the ground lug near the input power block on this machine. Without proper grounding, personal injury from electric shock could occur and machine malfunctions may be evident.

SW008

Electrical connections are made at the rear of the machine. The machine must be connected to the proper electrical supply shown on the identification plate attached to the rear of the machine, using copper conductors only.

IMPORTANT: Alliance Laundry Systems warranty does not cover components that fail as a result of improper input voltage.

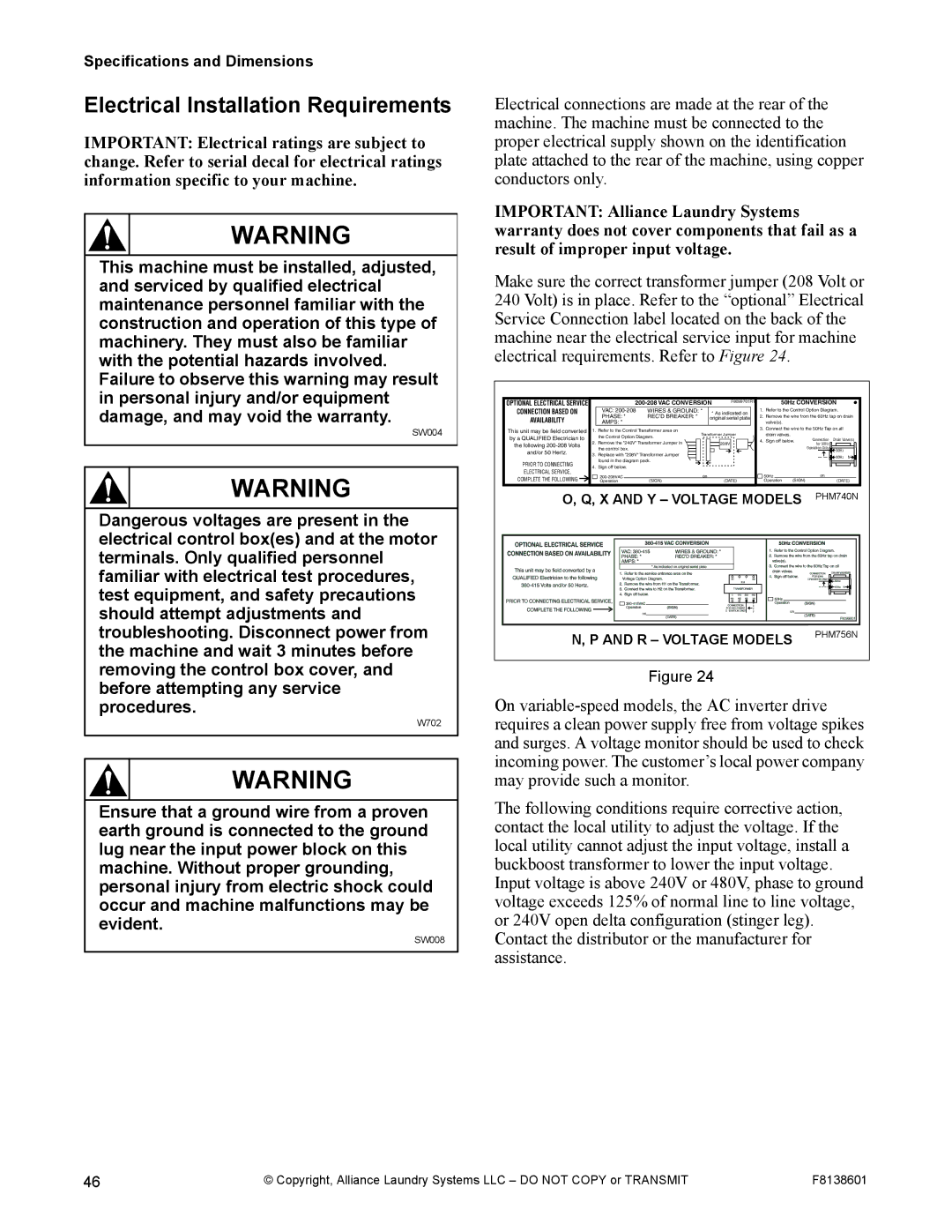

Make sure the correct transformer jumper (208 Volt or 240 Volt) is in place. Refer to the “optional” Electrical Service Connection label located on the back of the machine near the electrical service input for machine electrical requirements. Refer to Figure 24.

OPTIONAL ELECTRICAL SERVICE | F8099701R1 | 50Hz CONVERSION | |||||||

| |||||||||

CONNECTION BASED ON | VAC: | WIRES & GROUND: * |

| * As indicated on | 1. Refer to the Control Option Diagram. | ||||

AVAILABILITY | PHASE: * | REC'D BREAKER: * |

| original serial plate | 2. Remove the wire from the 60Hz tap on drain | ||||

AMPS: * |

|

|

|

| valve(s). |

|

|

| |

This unit may be field converted 1. Refer to the Control Transformer area on |

|

|

| 3. Connect the wire to the 50Hz Tap on all | |||||

Transformer Jumper | drain valves. |

|

|

| |||||

by a QUALIFIED Electrician to | the Control Option Diagram. |

|

|

| |||||

2. Remove the "240V" Transformer Jumper in |

|

| 208V | 4. Sign off below. | Connection Drain Valve(s) | ||||

the following |

|

|

|

| for 50Hz |

| |||

the control box. |

|

|

|

|

|

| Operation Only | 50Hz | |

and/or 50 Hertz. |

|

|

|

|

|

|

| ||

3. Replace with "208V" Transformer Jumper |

|

|

|

|

|

| 60Hz N | ||

| found in the diagram pack. |

|

|

|

|

|

| ||

PRIOR TO CONNECTING |

|

|

|

|

|

|

| ||

4. Sign off below. |

|

|

|

|

|

|

|

| |

ELECTRICAL SERVICE, |

|

| on |

| 50Hz |

| on |

| |

COMPLETE THE FOLLOWING |

|

|

| (SIGN) |

| ||||

Operation | (SIGN) |

|

| (DATE) | Operation |

| (DATE) | ||

O, Q, X AND Y – VOLTAGE MODELS | PHM740N | ||||||||

N, P AND R – VOLTAGE MODELS | PHM756N |

|

Figure 24

On

The following conditions require corrective action, contact the local utility to adjust the voltage. If the local utility cannot adjust the input voltage, install a buckboost transformer to lower the input voltage. Input voltage is above 240V or 480V, phase to ground voltage exceeds 125% of normal line to line voltage, or 240V open delta configuration (stinger leg). Contact the distributor or the manufacturer for assistance.

46 | © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT | F8138601 |