Cook, Hold, Smoke Oven Deluxe Control, 1767-SK/III, 1000-SK/III, 300-TH/III, 1200-SK/III specifications

The Alto-Shaam 1200-TH/III is a revolutionary piece of equipment designed to meet the demands of modern commercial kitchens, blending innovative technology with user-friendly features. Renowned for its versatile capabilities, this model stands out as a reliable solution for restaurants, deli operations, and other foodservice establishments seeking to enhance their cooking and holding processes.At the heart of the Alto-Shaam 1200-TH/III is its advanced Halo Heat technology. This patented system provides uniform heat distribution while maintaining the perfect serving temperature for a variety of foods. Unlike traditional holding equipment that uses aggressive heat sources, the Halo Heat system gently surrounds food with radiant heat, ensuring it remains moist and flavorful without excessive cooking or drying out. This is particularly beneficial for items such as meats, poultry, and prepared side dishes.

The 1200-TH/III features a capacity that is ideal for high-volume operations, with ample space to hold multiple pans of different sizes. This flexible space allows operators to maximize efficiency during peak service times. The unit is designed to accommodate a variety of food presentation styles, making it suitable for buffet setups, catering, or quick-service environments.

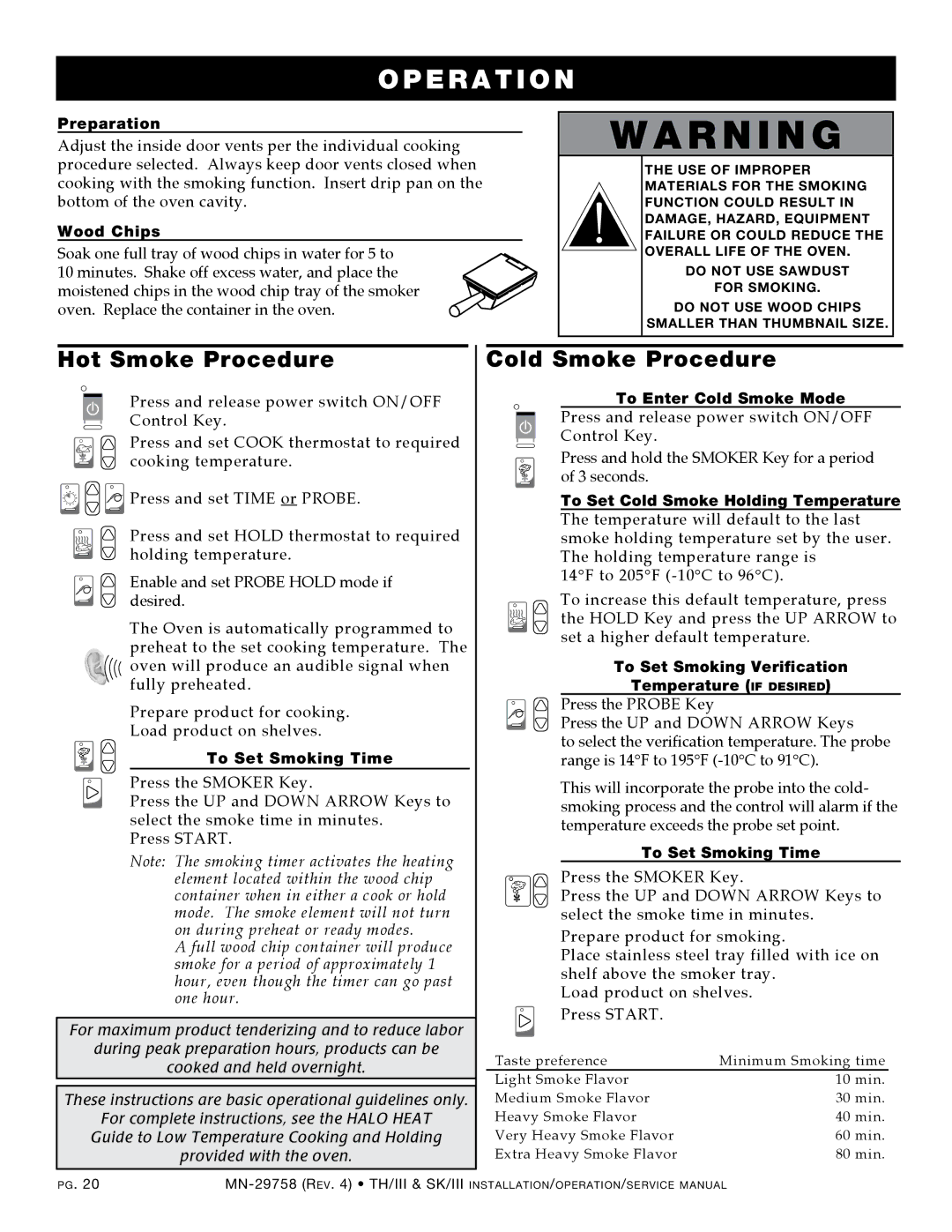

Another commendable feature of the Alto-Shaam 1200-TH/III is its user-friendly digital control panel. The intuitive interface allows for precise temperature control and monitoring, enabling staff to maintain optimal food conditions with minimal training. With programmable settings, users can easily establish different temperature profiles for various food items, streamlining the management of food service operations.

The construction of the Alto-Shaam 1200-TH/III emphasizes durability and ease of maintenance. Built from high-quality stainless steel, it resists corrosion and wear from daily use. Additionally, its removable racks and smooth surfaces facilitate easy cleaning, ensuring compliance with health regulations and promoting a hygienic kitchen environment.

Energy efficiency is another highlight of the Alto-Shaam 1200-TH/III. The innovative design not only reduces energy consumption but also contributes to lower operational costs, making it an economically sound choice for foodservice businesses.

In summary, the Alto-Shaam 1200-TH/III combines advanced technology with practical features to provide a top-tier solution for food holding and serving. Its Halo Heat technology, ample capacity, user-friendly controls, durable construction, and energy-efficient operation make it an essential addition to any commercial kitchen looking to improve food quality and service efficiency.