5 - If called for by point. 3, dismantling and cleaning of the combustion chamber.

6 - If called for by point. 4, dismantling and cleaning of the burner jets.

7 - Visual check of the primary heat exchanger:

-check for overheating in the blade assembly;

-clean the exhaust fan if needed.

8 - Adjustment of the flow rate of the gas: flow rate for lighting, partial load and full load.

9 - Check of the heating safety systems:

-safety device for maximum temperature;

-safety device for maximum pressure.

10- Check of the gas safety systems:

-safety device for lack of gas or flame ionisation (detection electrode);

-safety device for gas cock.

11- Check of the electrical connection (make sure it complies with the instructions in the manual).

12- Check of domestic hot water production efficiency (flow rate and temperature) 13- General check of the combustion

system.

14- Check of the general performance of the unit.

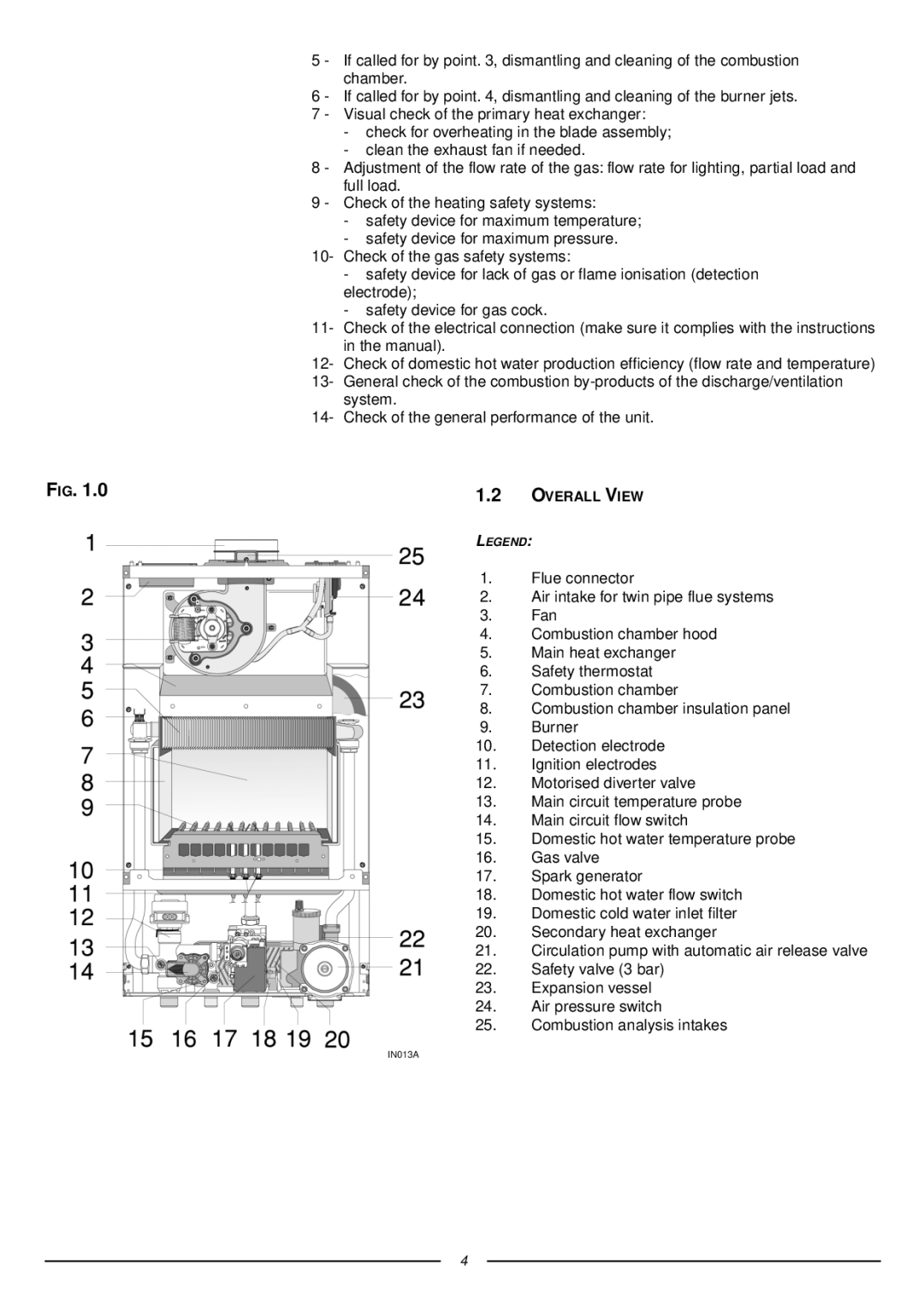

FIG. 1.0 | 1.2 OVERALL VIEW |

LEGEND:

1. Flue connector

2. Air intake for twin pipe flue systems

3. Fan

4. Combustion chamber hood

5. Main heat exchanger

6. Safety thermostat

7. Combustion chamber

8. Combustion chamber insulation panel

9. Burner

10. Detection electrode

11. Ignition electrodes

12. Motorised diverter valve

13. Main circuit temperature probe

14. Main circuit flow switch

15. Domestic hot water temperature probe

16. Gas valve

17. Spark generator

18. Domestic hot water flow switch

19. Domestic cold water inlet filter

20. Secondary heat exchanger

21. Circulation pump with automatic air release valve

22. Safety valve (3 bar)

23. Expansion vessel

24. Air pressure switch

25. Combustion analysis intakes

IN013A

4