![]() BM 2610027879

BM 2610027879

preparing for Saw Operations

Making an Auxiliary fence

Certain types of molding need a fence face extension because of the size and position of the workpiece. Holes are provided in the fence to attach an auxiliary fence. The auxiliary fence is used with the saw in the

0° bevel position only.

1.Place a piece of wood against the miter saw fence (see Figure 36). Wood can have a maximum height of

2.Mark the locations of the support holes on the wood from the back side of the fence.

3.Drill and countersink the holes on the front of the support board.

4.Fasten from front of fence: Attach (each) auxiliary fence using two (2) 3/16" flat head machine screws. With 3/4" auxiliary fence, use

Fasten from back of fence: With 3/4" auxiliary fence, use 1/4" round head wood screws (3/4" long). Drill four pilot holes through auxiliary fence and run screws from rear of metal fence.

5.Make a full depth cut to create the blade slot. Check for interference between the auxiliary fence and the lower blade guard. Make adjustments as necessary.

6.For best

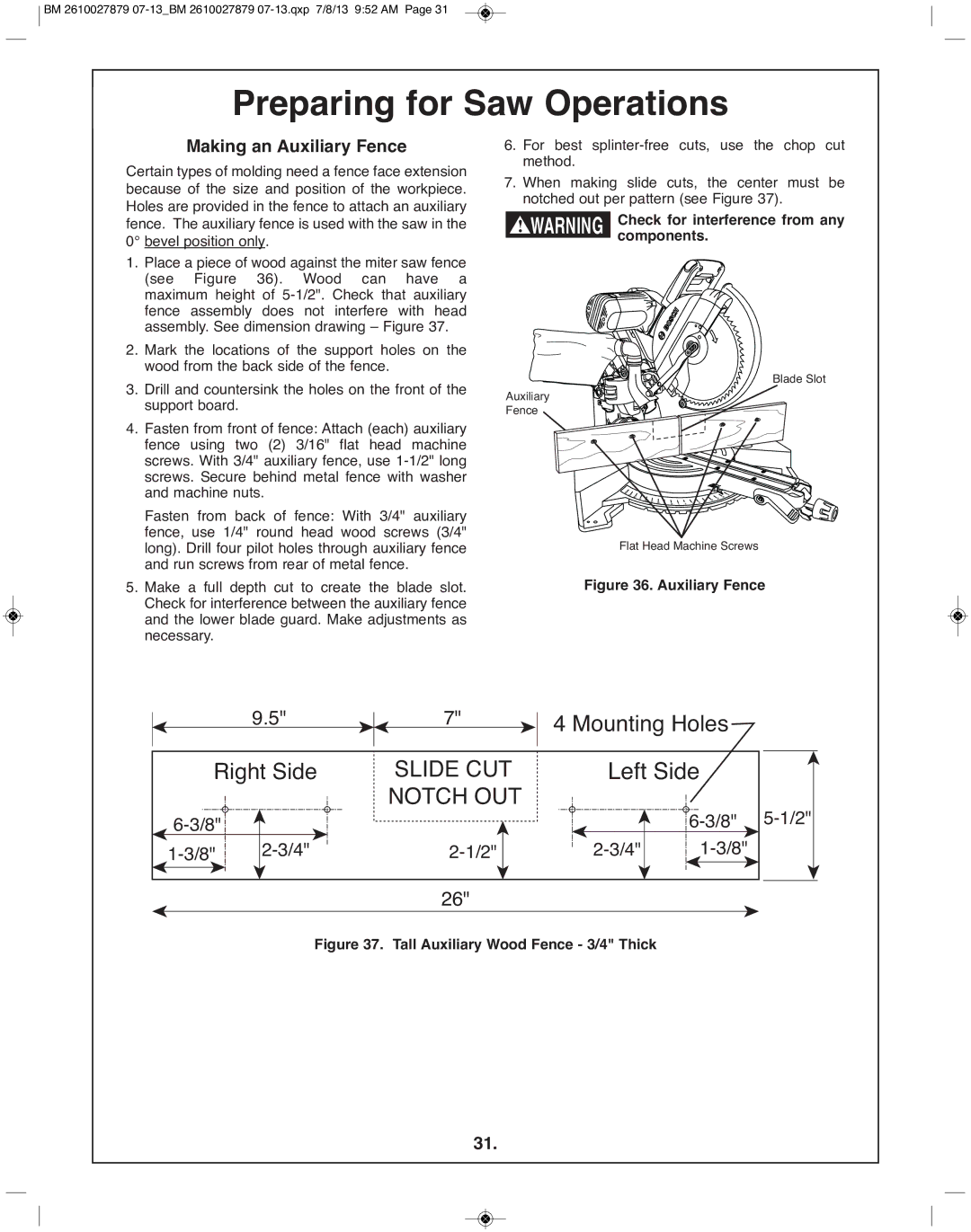

7.When making slide cuts, the center must be notched out per pattern (see Figure 37).

!WARNING Check for interference from any components.

Blade Slot

Auxiliary

Fence

Flat Head Machine Screws

figure 36. Auxiliary fence

9.5"

7"

4 Mounting Holes

Right Side | SLIDE CUT | Left Side |

| ||

| NOTCH OUT |

| |||

|

|

| |||

| |||||

|

| 26" |

|

|

|

| figure 37. Tall Auxiliary Wood fence - 3/4" Thick |

|

| ||

31.