![]() BM 2610027879

BM 2610027879

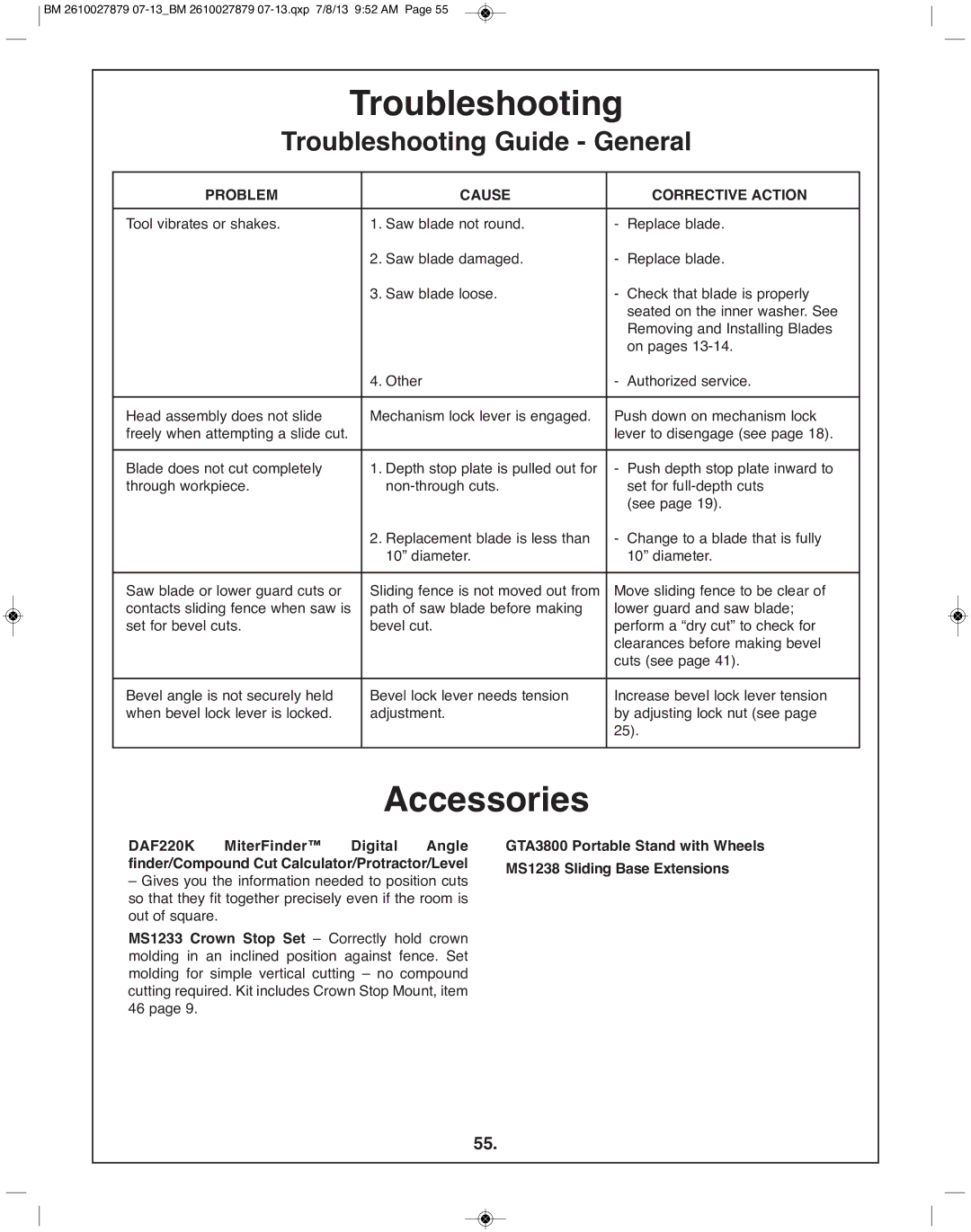

Troubleshooting

Troubleshooting Guide - General

pROBlEM |

| CAUSE |

| CORRECTIVE ACTION |

|

|

|

|

|

Tool vibrates or shakes. | 1. | Saw blade not round. | - | Replace blade. |

| 2. Saw blade damaged. | - | Replace blade. | |

| 3. | Saw blade loose. | - | Check that blade is properly |

|

|

|

| seated on the inner washer. See |

|

|

|

| Removing and Installing Blades |

|

|

|

| on pages |

| 4. | Other | - | Authorized service. |

|

|

| ||

Head assembly does not slide | Mechanism lock lever is engaged. | Push down on mechanism lock | ||

freely when attempting a slide cut. |

|

| lever to disengage (see page 18). | |

|

|

|

|

|

Blade does not cut completely | 1. | Depth stop plate is pulled out for | - | Push depth stop plate inward to |

through workpiece. |

|

| set for | |

|

|

|

| (see page 19). |

| 2. | Replacement blade is less than | - | Change to a blade that is fully |

|

| 10” diameter. |

| 10” diameter. |

|

|

| ||

Saw blade or lower guard cuts or | Sliding fence is not moved out from | Move sliding fence to be clear of | ||

contacts sliding fence when saw is | path of saw blade before making | lower guard and saw blade; | ||

set for bevel cuts. | bevel cut. | perform a “dry cut” to check for | ||

|

|

| clearances before making bevel | |

|

|

| cuts (see page 41). | |

|

|

| ||

Bevel angle is not securely held | Bevel lock lever needs tension | Increase bevel lock lever tension | ||

when bevel lock lever is locked. | adjustment. | by adjusting lock nut (see page | ||

|

|

| 25). | |

|

|

|

|

|

Accessories

DAf220K Miterfinder™ Digital Angle finder/Compound Cut Calculator/protractor/level

–Gives you the information needed to position cuts so that they fit together precisely even if the room is out of square.

MS1233 Crown Stop Set – Correctly hold crown molding in an inclined position against fence. Set molding for simple vertical cutting – no compound cutting required. Kit includes Crown Stop Mount, item 46 page 9.

GTA3800 portable Stand with Wheels

MS1238 Sliding Base Extensions

55.