![]() BM 2610027879

BM 2610027879

Adjustments

Miter Detent System – Adjustment procedure

Calibrating Miter Detent System

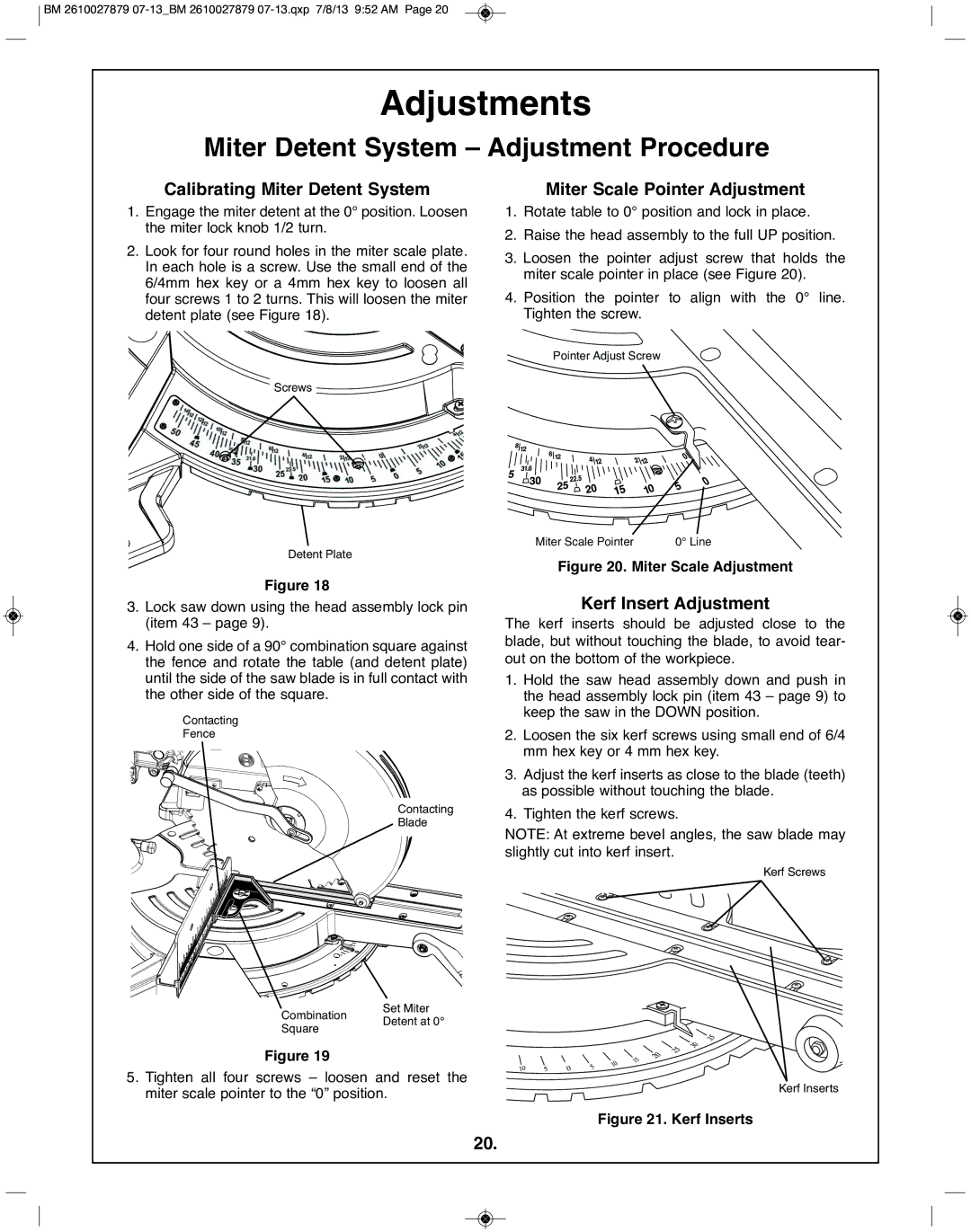

1.Engage the miter detent at the 0° position. Loosen the miter lock knob 1/2 turn.

2.Look for four round holes in the miter scale plate. In each hole is a screw. Use the small end of the 6/4mm hex key or a 4mm hex key to loosen all four screws 1 to 2 turns. This will loosen the miter detent plate (see Figure 18).

Screws

Detent Plate

figure 18

3.Lock saw down using the head assembly lock pin (item 43 – page 9).

4.Hold one side of a 90° combination square against the fence and rotate the table (and detent plate) until the side of the saw blade is in full contact with the other side of the square.

Contacting

Fence

Contacting

Blade

Combination | Set Miter | |

Detent at 0° | ||

Square | ||

|

figure 19

5.Tighten all four screws – loosen and reset the miter scale pointer to the “0” position.

Miter Scale pointer Adjustment

1.Rotate table to 0° position and lock in place.

2.Raise the head assembly to the full UP position.

3.Loosen the pointer adjust screw that holds the miter scale pointer in place (see Figure 20).

4.Position the pointer to align with the 0° line. Tighten the screw.

Pointer Adjust Screw

Miter Scale Pointer | 0° Line |

figure 20. Miter Scale Adjustment

Kerf Insert Adjustment

The kerf inserts should be adjusted close to the blade, but without touching the blade, to avoid tear- out on the bottom of the workpiece.

1.Hold the saw head assembly down and push in the head assembly lock pin (item 43 – page 9) to keep the saw in the DOWN position.

2.Loosen the six kerf screws using small end of 6/4 mm hex key or 4 mm hex key.

3.Adjust the kerf inserts as close to the blade (teeth) as possible without touching the blade.

4.Tighten the kerf screws.

NOTE: At extreme bevel angles, the saw blade may slightly cut into kerf insert.

Kerf Screws

Kerf Inserts

figure 21. Kerf Inserts

20.