![]() BM 2610027879

BM 2610027879

Saw Operations

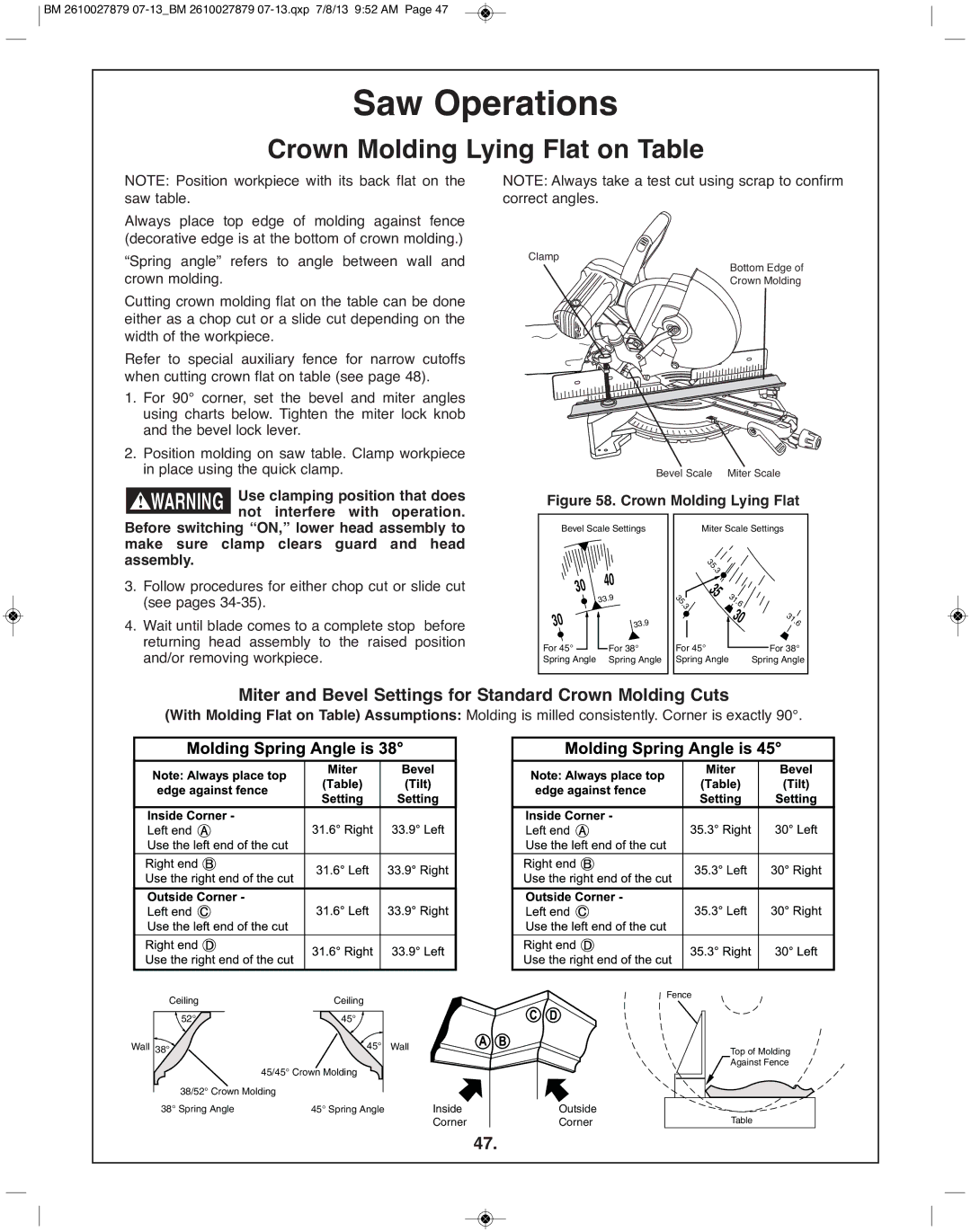

Crown Molding lying flat on Table

NOTE: Position workpiece with its back flat on the saw table.

Always place top edge of molding against fence (decorative edge is at the bottom of crown molding.)

“Spring angle” refers to angle between wall and crown molding.

Cutting crown molding flat on the table can be done either as a chop cut or a slide cut depending on the width of the workpiece.

Refer to special auxiliary fence for narrow cutoffs when cutting crown flat on table (see page 48).

1.For 90° corner, set the bevel and miter angles using charts below. Tighten the miter lock knob and the bevel lock lever.

2.Position molding on saw table. Clamp workpiece in place using the quick clamp.

!WARNING Use clamping position that does not interfere with operation.

NOTE: Always take a test cut using scrap to confirm correct angles.

Clamp

Bottom Edge of

Crown Molding

Bevel Scale Miter Scale

figure 58. Crown Molding lying flat

Before switching “ON,” lower head assembly to make sure clamp clears guard and head assembly.

3.Follow procedures for either chop cut or slide cut (see pages

4.Wait until blade comes to a complete stop before returning head assembly to the raised position and/or removing workpiece.

Bevel Scale Settings

30 | 40 | |

.9 | ||

| ||

| 33 | |

30 | 33 | |

| .9 | |

For 45° | For 38° | |

Spring Angle | Spring Angle |

Miter Scale Settings

35 |

|

|

. |

|

|

3 |

|

|

35 | 31. |

|

35 |

| |

6 |

| |

. |

| |

3 | 30 |

|

| 31. | |

|

| 6 |

For 45° |

| For 38° |

Spring Angle | Spring Angle | |

Miter and Bevel Settings for Standard Crown Molding Cuts

(With Molding flat on Table) Assumptions: Molding is milled consistently. Corner is exactly 90°.

Ceiling | Ceiling |

|

52° | 45° |

|

Wall 38° | 45° | Wall |

| 45/45° Crown Molding |

|

38/52° Crown Molding |

| |

38° Spring Angle | 45° Spring Angle | Inside |

|

| Corner |

Outside Corner

Fence |

Top of Molding |

Against Fence |

Table |

47.