![]() BM 2610021316

BM 2610021316

Basic Saw Operations

A

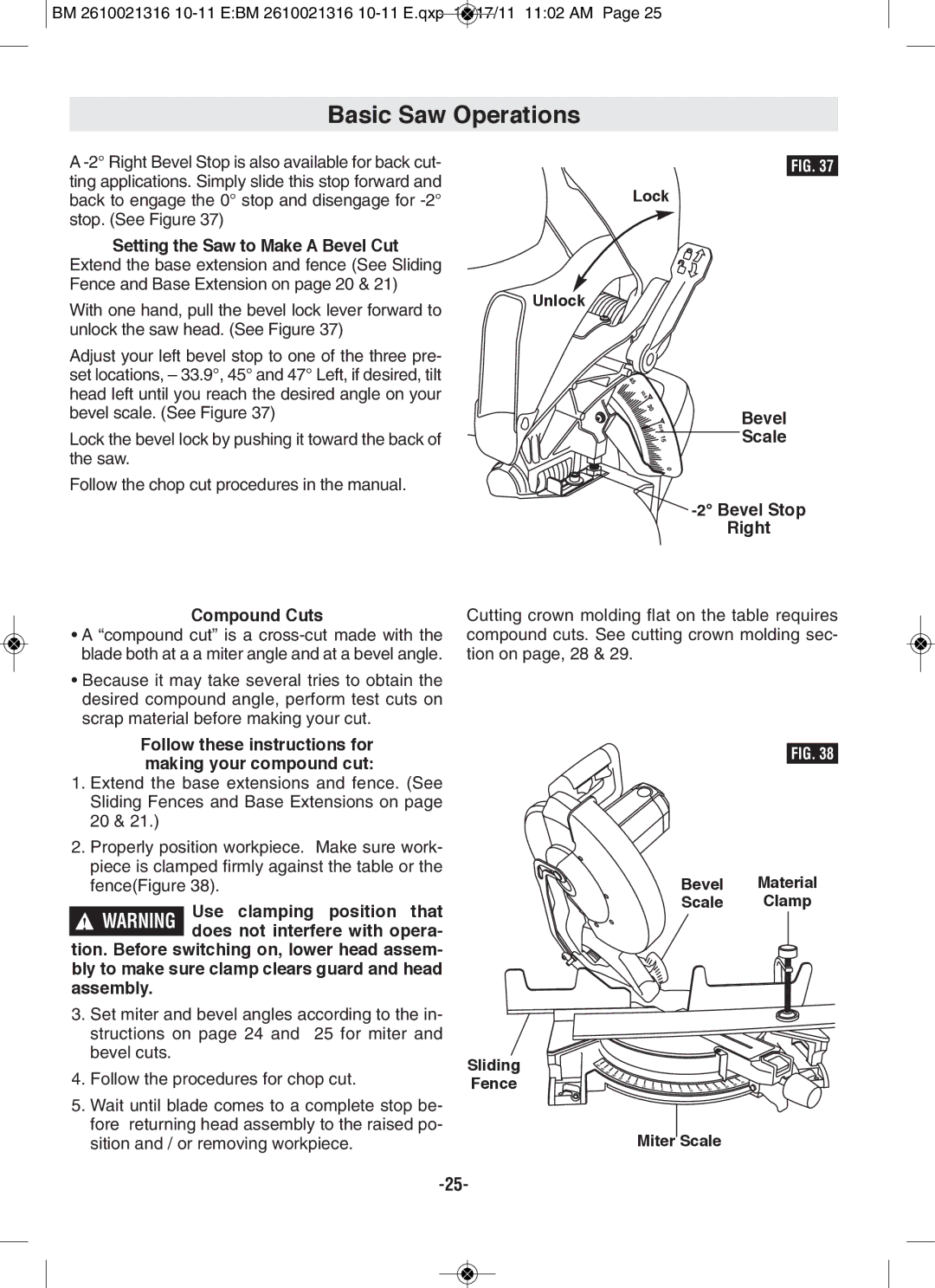

Setting the Saw to Make A Bevel Cut

Extend the base extension and fence (See Sliding Fence and Base Extension on page 20 & 21)

With one hand, pull the bevel lock lever forward to unlock the saw head. (See Figure 37)

Adjust your left bevel stop to one of the three pre- set locations, – 33.9°, 45° and 47° Left, if desired, tilt head left until you reach the desired angle on your bevel scale. (See Figure 37)

Lock the bevel lock by pushing it toward the back of the saw.

Follow the chop cut procedures in the manual.

Compound Cuts

•A “compound cut” is a

•Because it may take several tries to obtain the desired compound angle, perform test cuts on scrap material before making your cut.

follow these instructions for making your compound cut:

1.Extend the base extensions and fence. (See Sliding Fences and Base Extensions on page 20 & 21.)

2.Properly position workpiece. Make sure work- piece is clamped firmly against the table or the fence(Figure 38).

!WARNING Use clamping position that does not interfere with opera-

tion. Before switching on, lower head assem- bly to make sure clamp clears guard and head assembly.

3.Set miter and bevel angles according to the in- structions on page 24 and 25 for miter and bevel cuts.

4.Follow the procedures for chop cut.

5.Wait until blade comes to a complete stop be- fore returning head assembly to the raised po- sition and / or removing workpiece.

FIG. 37

lock

Unlock

Bevel

Scale

-2° Bevel Stop

Right

Cutting crown molding flat on the table requires compound cuts. See cutting crown molding sec- tion on page, 28 & 29.

FIG. 38